A High-Power Millimeter-Wave Broadband Mode Converter Based on Continuous Grating Structure

A mode conversion and grating structure technology, which is applied to waveguide-type devices, connecting devices, antennas, etc., can solve the problems of easy breakdown of grating mirrors, low output mode purity, discontinuous grating mirrors, etc., to facilitate heat dissipation and design. Cooling structure, high purity output mode, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The patent will be further explained below in conjunction with the drawings.

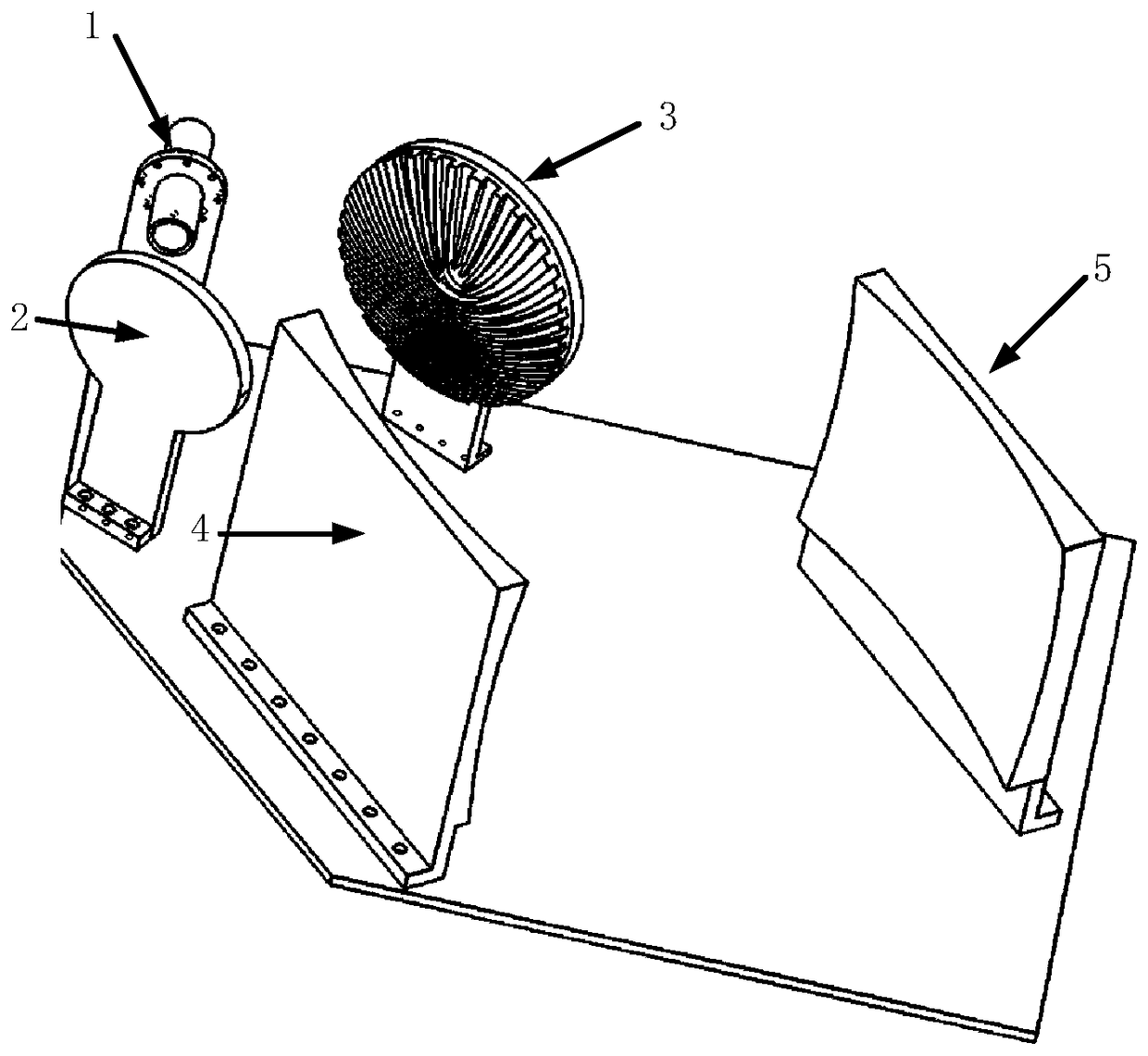

[0028] A high-power millimeter-wave broadband mode converter based on a continuous grating structure includes: a circular waveguide radiator (1), a matching mirror (2), a polarization grating mirror (3), and a phase correction system, wherein the phase correction system consists of two sides The phase correction mirrors (4) and (5) are composed, and the above components are all placed in the same metal cavity.

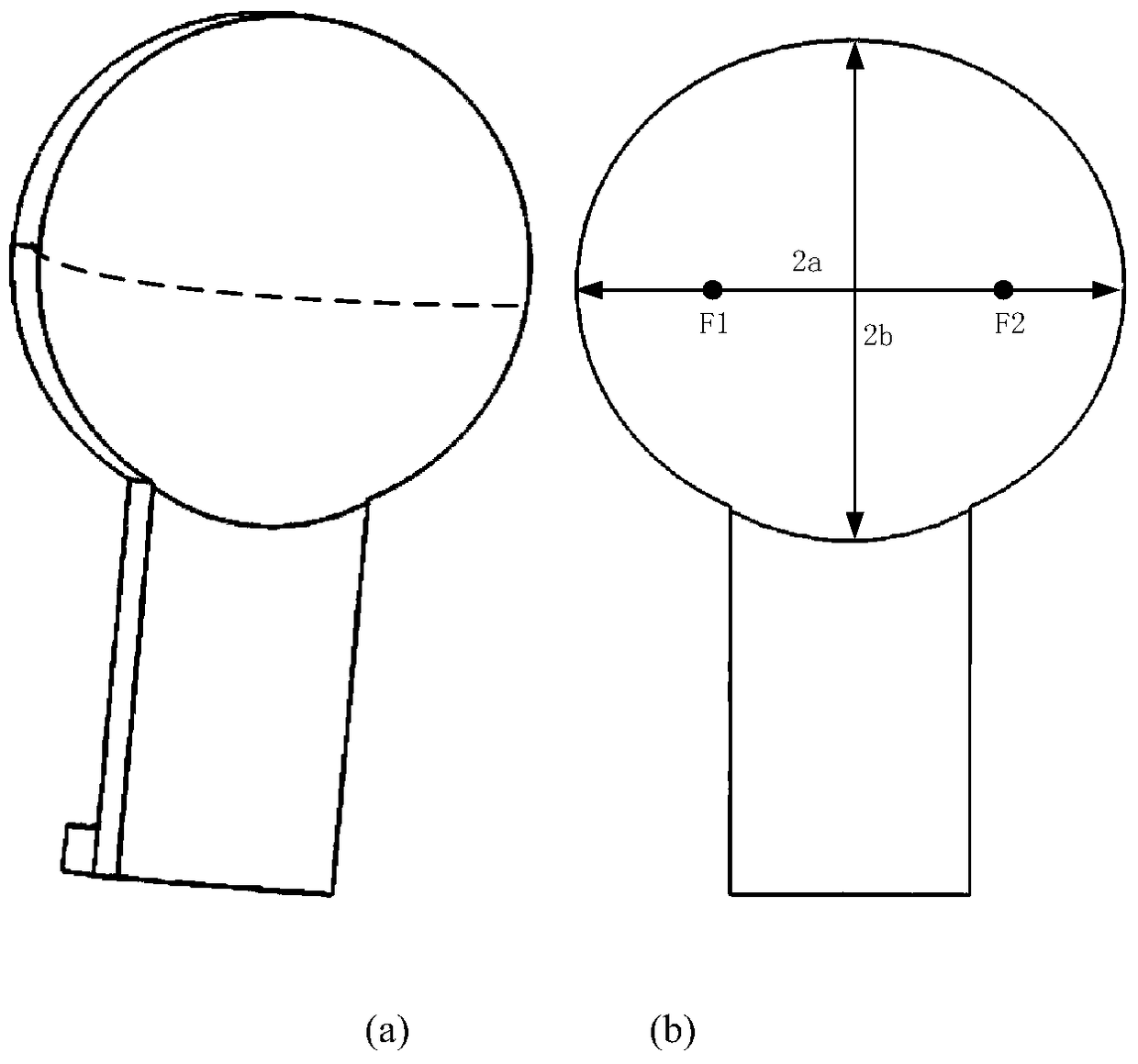

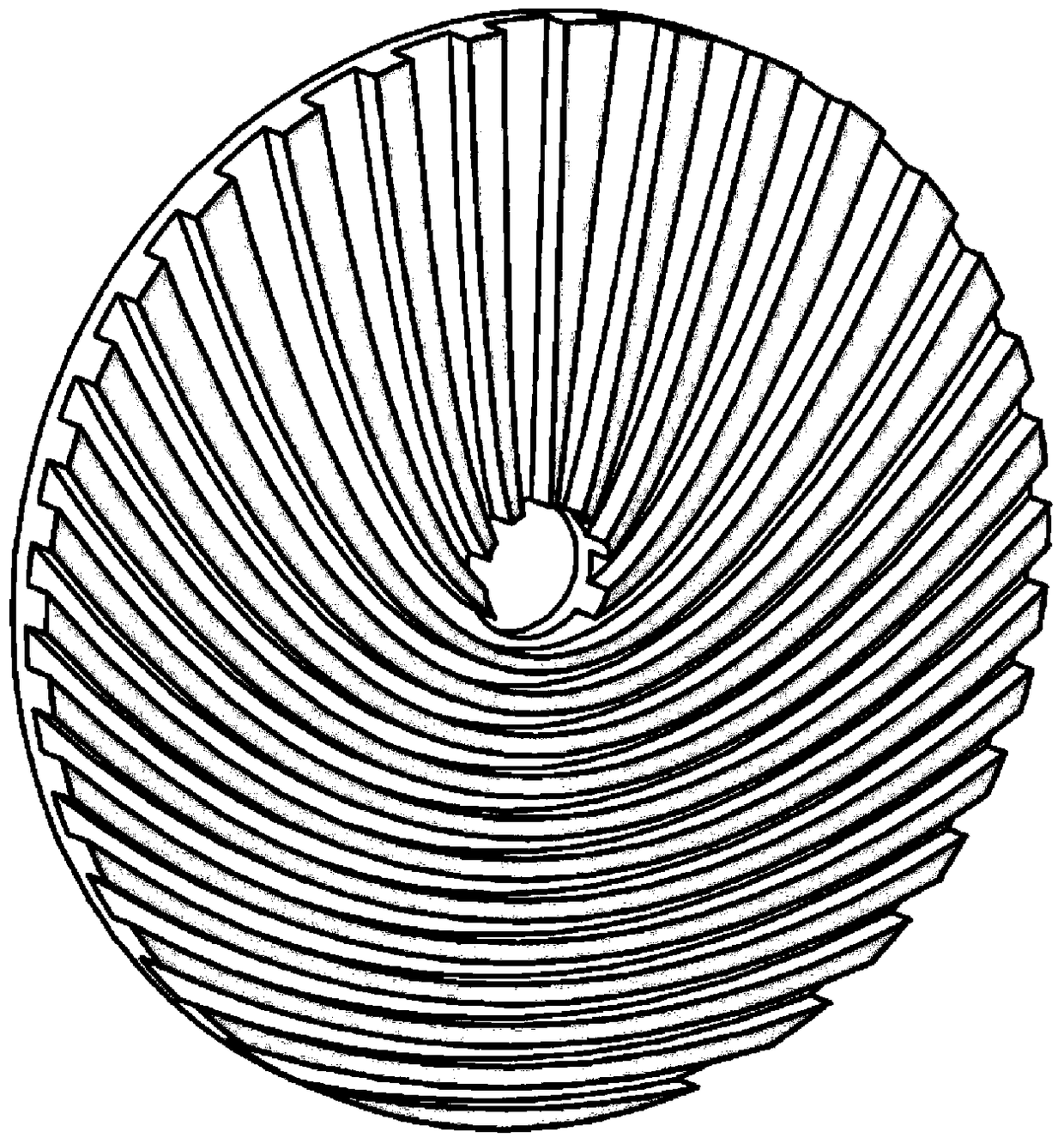

[0029] The radius of the circular waveguide radiator is equal to the high-power millimeter wave TE 0,1 Mode-TEM 00 The radius of the output port of the upstream device connected to the mode converter of the mode; the matching mirror is an ellipsoidal mirror, and its mirror direction is at an angle of 45 degrees with the axis of the open circular waveguide; the polarized grating mirror is a continuous variable-period reflection with a central opening Grating mirror, the normal of the polari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com