Method for preparing cerium dioxide/two-dimensional layered titanium carbide composite material through precipitation process

A ceria, two-dimensional layered technology, which is applied in the field of preparation of ceria/two-dimensional layered titanium carbide composite materials by precipitation method, can solve the problems of not suitable for mass production, narrow application range, small surface area, etc., and achieve load The method is simple and effective, the shape is diverse, and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, refine the powder

[0031] Refinement of ternary layered Ti with a purity greater than 97 wt% by high energy ball milling 3 AlC 2 Ceramic powder, ball milling conditions: the mass ratio of ball stone, mixing material and absolute ethanol is 10:1:1, the ball milling speed is 350r / min, the high energy ball milling time is 2h, and then the obtained solid-liquid mixture is baked at 40°C Dry, get Ti 3 AlC 2 ceramic powder;

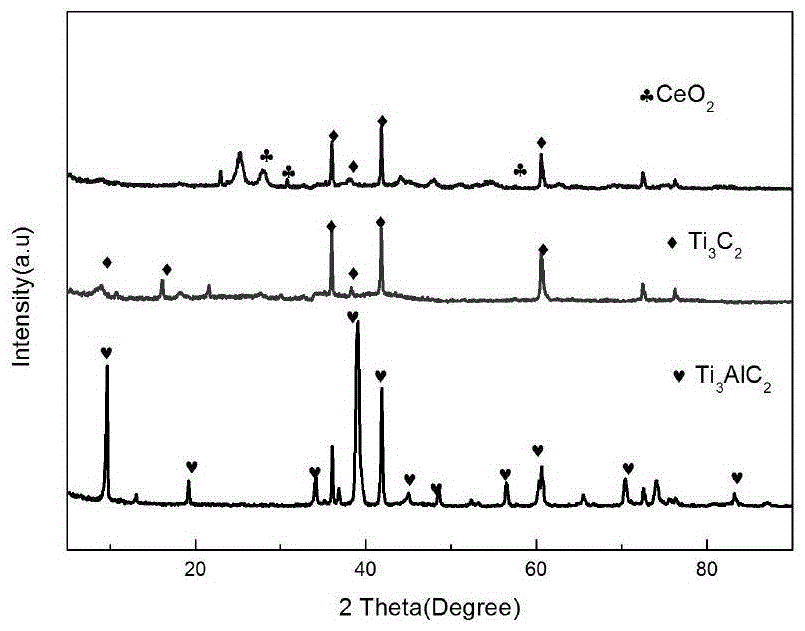

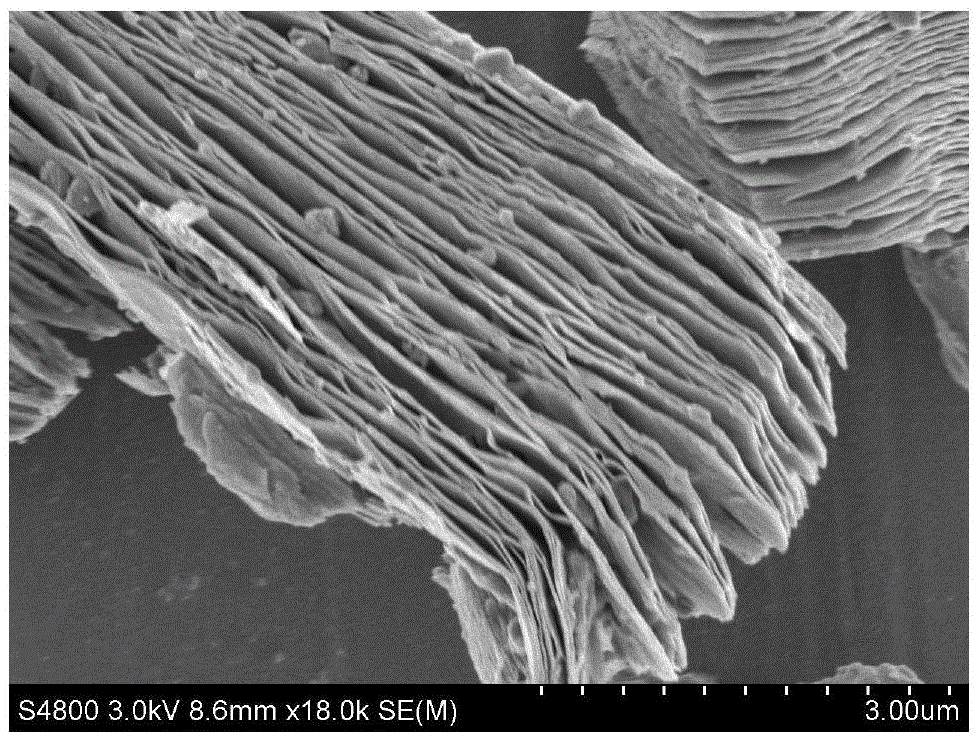

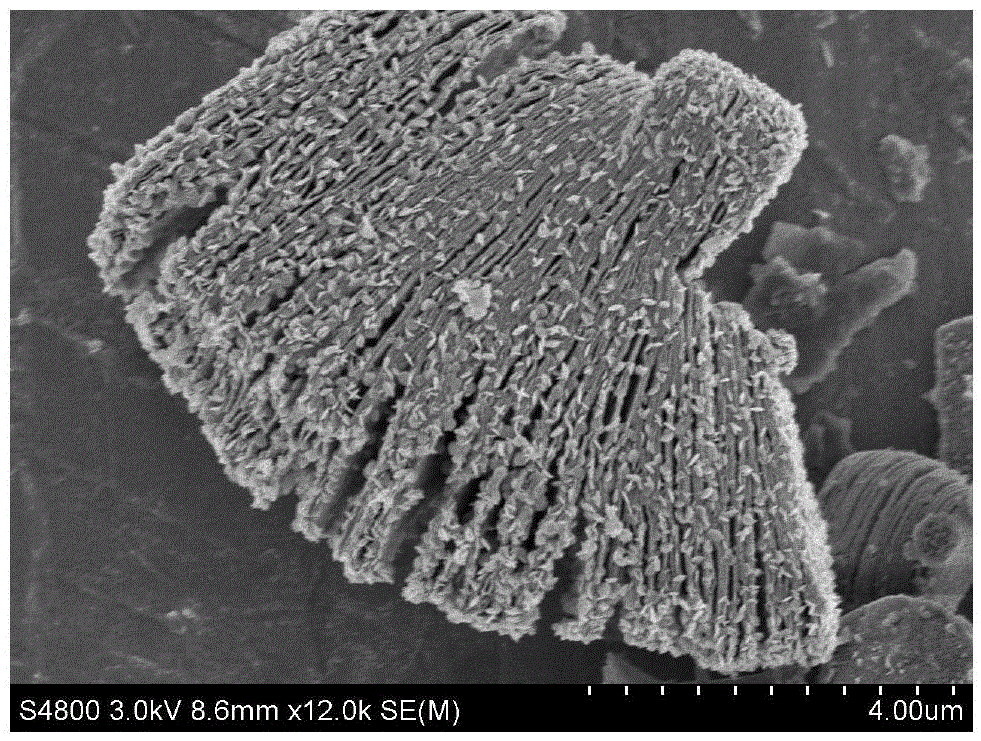

[0032] Step 2, two-dimensional layered nanomaterial MXene-Ti 3 C 2 preparation of

[0033] Ti obtained in step 1 3 AlC 2 The ceramic powder is immersed in HF acid solution, in which 5gTi 3 AlC 2 The powder was immersed in 80ml mass concentration of 40wt% HF acid solution and reacted for 24h; magnetic stirring, the Ti 3 AlC 2 After the powder was corroded, it was centrifugally washed with deionized water until the pH was 6, and the obtained solid sample was dried at room temperature to obtain the two-dimensional layered nanomaterial MX...

Embodiment 2

[0041] Step 1, refine the powder

[0042] Refinement of ternary layered Ti with a purity greater than 97 wt% by high energy ball milling 3 AlC 2 Ceramic powder, ball milling conditions: the mass ratio of ball stone, mixing material and absolute ethanol is 10:1:1, the ball milling speed is 350r / min, the high energy ball milling time is 2h, and then the obtained solid-liquid mixture is baked at 40°C Dry, get Ti 3 AlC 2 ceramic powder;

[0043] Step 2, two-dimensional layered nanomaterial MXene-Ti 3 C 2 preparation of

[0044] Ti obtained in step 1 3 AlC 2 The ceramic powder is immersed in HF acid solution, in which 5gTi 3 AlC 2 The powder was immersed in 80ml mass concentration of 40wt% HF acid solution and reacted for 24h; magnetic stirring, the Ti 3 AlC 2 After the powder was corroded, it was centrifugally washed with deionized water until the pH was 6, and the obtained solid sample was dried at room temperature to obtain the two-dimensional layered nanomaterial MX...

Embodiment 3

[0052] Step 1, refine the powder

[0053] Refinement of ternary layered Ti with a purity greater than 97 wt% by high energy ball milling 3 AlC 2 Ceramic powder, ball milling conditions: the mass ratio of ball stone, mixing material and absolute ethanol is 10:1:1, the ball milling speed is 350r / min, the high energy ball milling time is 2h, and then the obtained solid-liquid mixture is baked at 40°C Dry, get Ti 3 AlC 2 ceramic powder;

[0054] Step 2, two-dimensional layered nanomaterial MXene-Ti 3 C 2 preparation of

[0055] Ti obtained in step 1 3 AlC 2 The ceramic powder is immersed in HF acid solution, in which 5gTi 3 AlC 2 The powder was immersed in 80ml mass concentration of 40wt% HF acid solution and reacted for 24h; magnetic stirring, the Ti 3 AlC 2 After the powder was corroded, it was centrifugally washed with deionized water until the pH was 6, and the obtained solid sample was dried at room temperature to obtain the two-dimensional layered nanomaterial MX...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com