Preparation method of zeolite support-based hydrodesulfurization catalyst

A hydrodesulfurization and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as deactivation of hydrodesulfurization catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

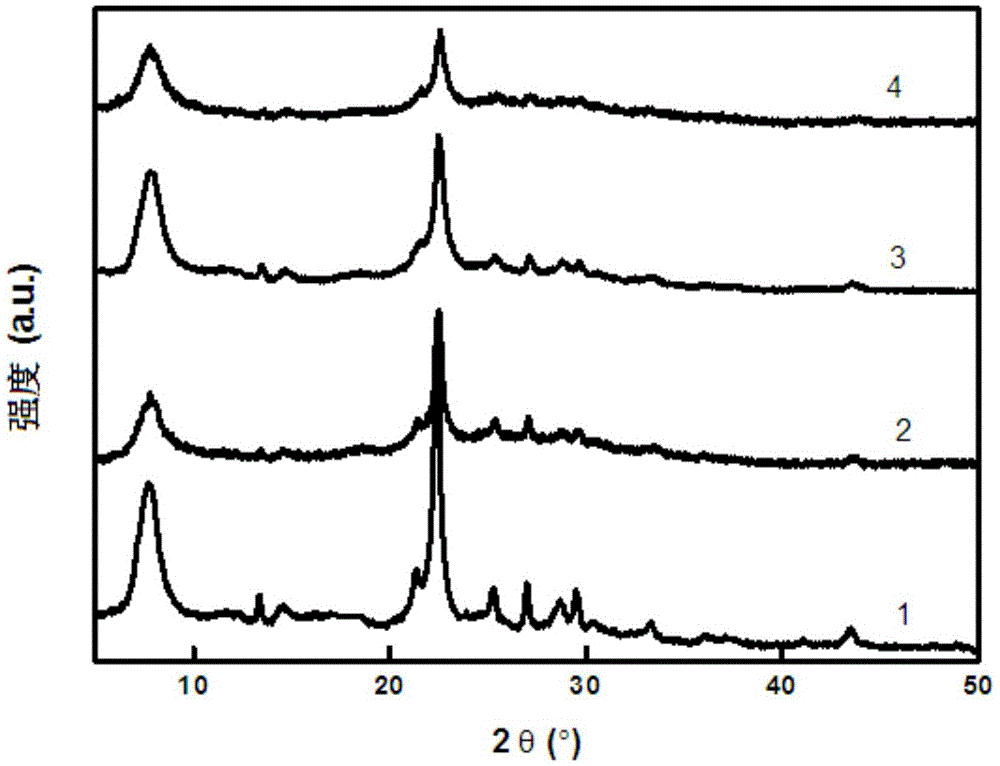

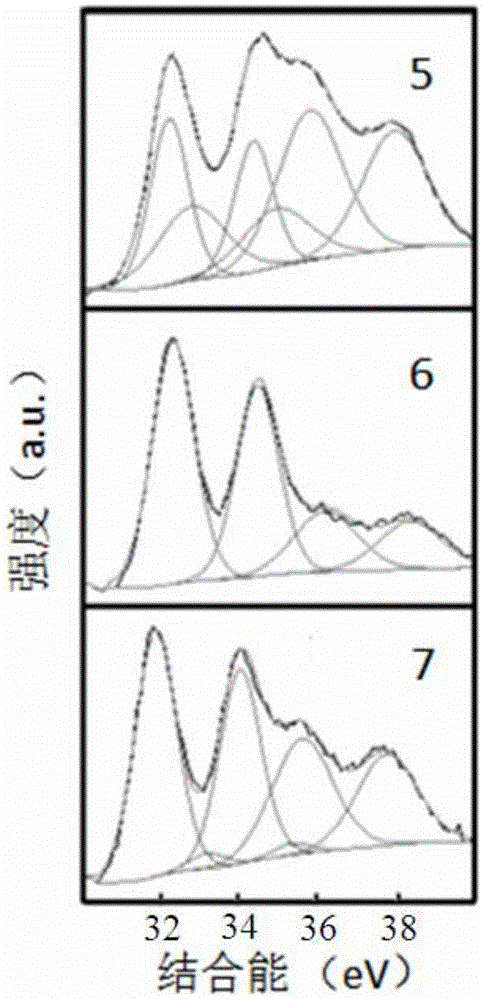

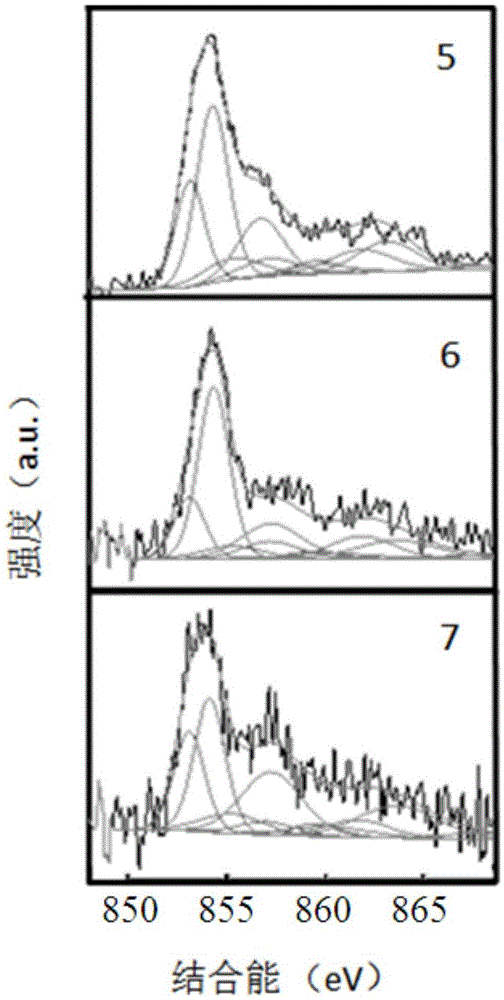

Image

Examples

specific Embodiment approach 1

[0041] Specific embodiment one: the preparation method of the hydrodesulfurization catalyst based on the zeolite carrier in this embodiment is carried out according to the following steps:

[0042] 1. Prepare nickel salt or cobalt salt and ammonium metatungstate, metatungstic acid or ammonium molybdate into an aqueous solution according to the atomic ratio of tungsten to nickel or cobalt in the ratio of 2 to 3:1, and use the aqueous solution to dry-impregnate the Nickel, cobalt, and tungsten are adsorbed on the desiliconized hierarchical zeolite and alumina carrier respectively, and then calcined at 500-600°C for 4.5-5.5h to obtain the nickel-tungsten catalyst supported by the desiliconized hierarchical zeolite and three A nickel-tungsten catalyst supported by alumina, wherein the mass percentage of tungsten trioxide in the nickel-tungsten catalyst supported by desiliconized hierarchical zeolite or the nickel-tungsten catalyst supported by alumina is 10% to 30%;

[0043] The nic...

specific Embodiment approach 2

[0047] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, the mass percentage of tungsten trioxide in the nickel-tungsten catalyst supported by hierarchically porous Beta zeolite or the nickel-tungsten catalyst supported by aluminum oxide is 12% to 28%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, tungsten trioxide is contained in the nickel-tungsten catalyst supported by hierarchically porous Beta zeolite or the nickel-tungsten catalyst supported by aluminum oxide. The mass percentage is 13% to 25%. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com