A Narrow Gap Welding Method for Standing Seam Position of Liquid Natural Gas Storage Tank

A technology of liquefied natural gas and welding method, which is applied in the direction of welding equipment, welding accessories, welding rod characteristics, etc., can solve the problems of low welding efficiency of ordinary TIG welding, difficult clamping of standing seam position, and difficult realization of actual production, etc., and achieves the improvement of welding construction Excellent efficiency, metallurgical properties and mechanical properties, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A narrow gap welding method at the standing seam position of a liquid natural gas storage tank, comprising the following steps:

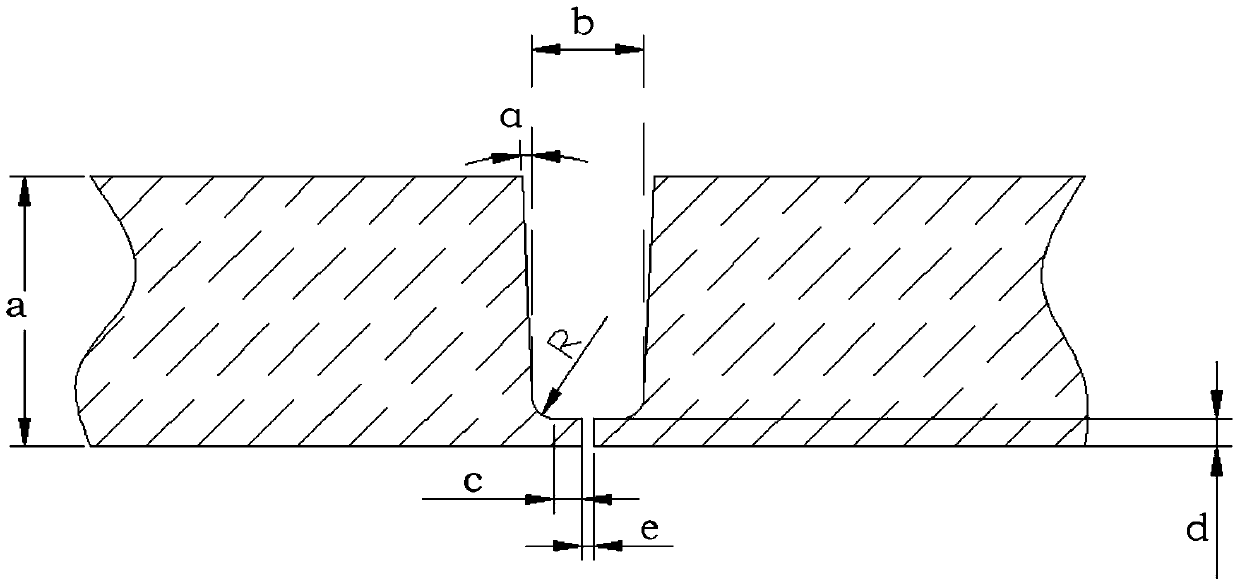

[0033] (1), Groove treatment: such as figure 1 As shown, the thickness of the plate is a=24mm, and the U-shaped groove with a narrow gap is opened for the thick plate, the groove gap b=10mm, blunt edges are reserved, and the groove is polished and derusted; the groove size is: ①The transition radius of the bottom arc R=2.0mm; ②The protruding length of the blunt edge c=2.5mm, the thickness of the blunt edge d=2.5mm; ③The gap e=1.0mm; ④The groove angle α=2.5°;

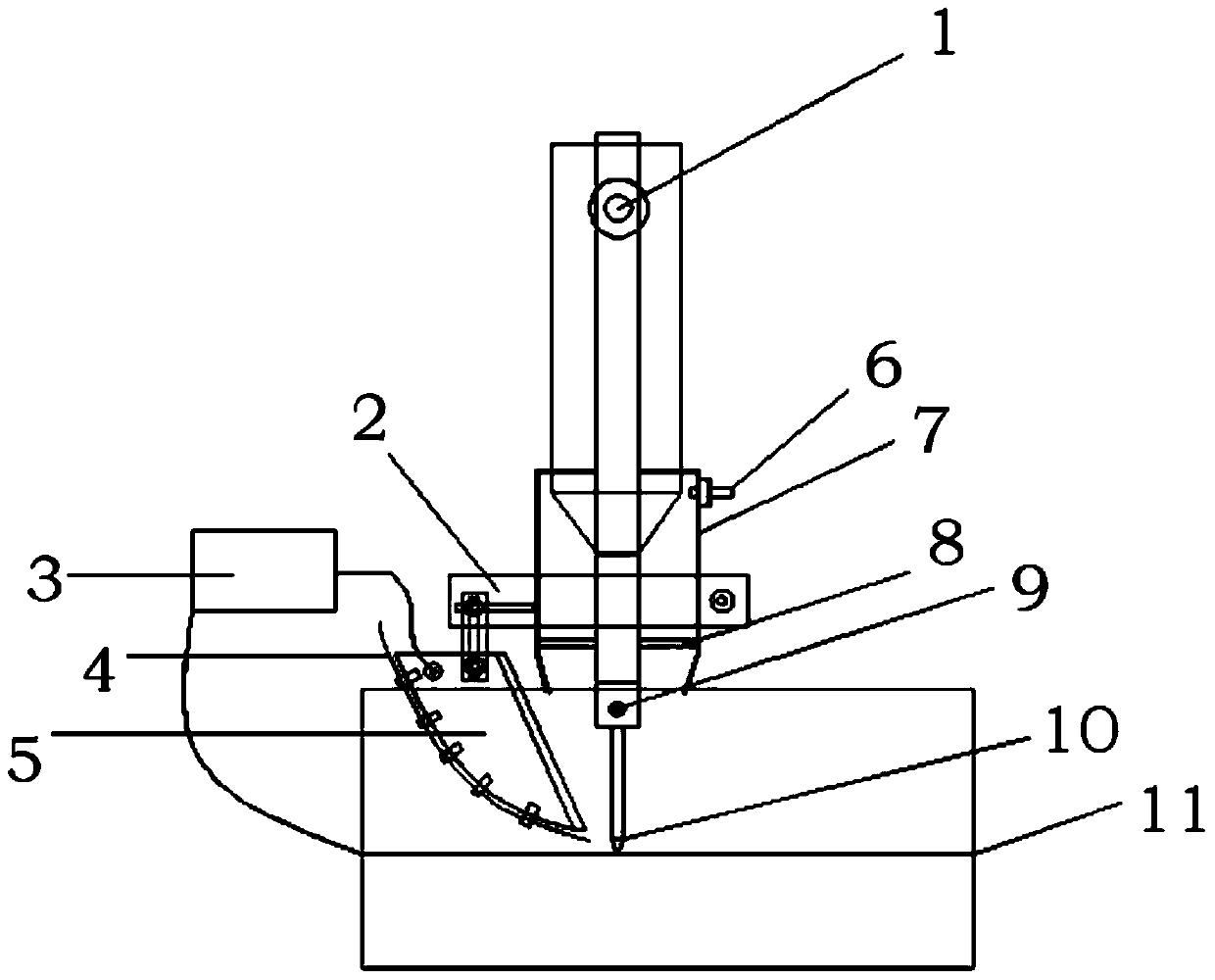

[0034] (2) Clamping: Use the existing LNG liquid storage tank wall-mounted trolley to fix two racks and brackets on the tank wall, and use the racks and brackets to achieve relative fixation between the crawling welding robot and the storage tank to achieve stable installation. Clamping, the clamping error is less than 1mm;

[0035] (3) Welding of opposite seams:

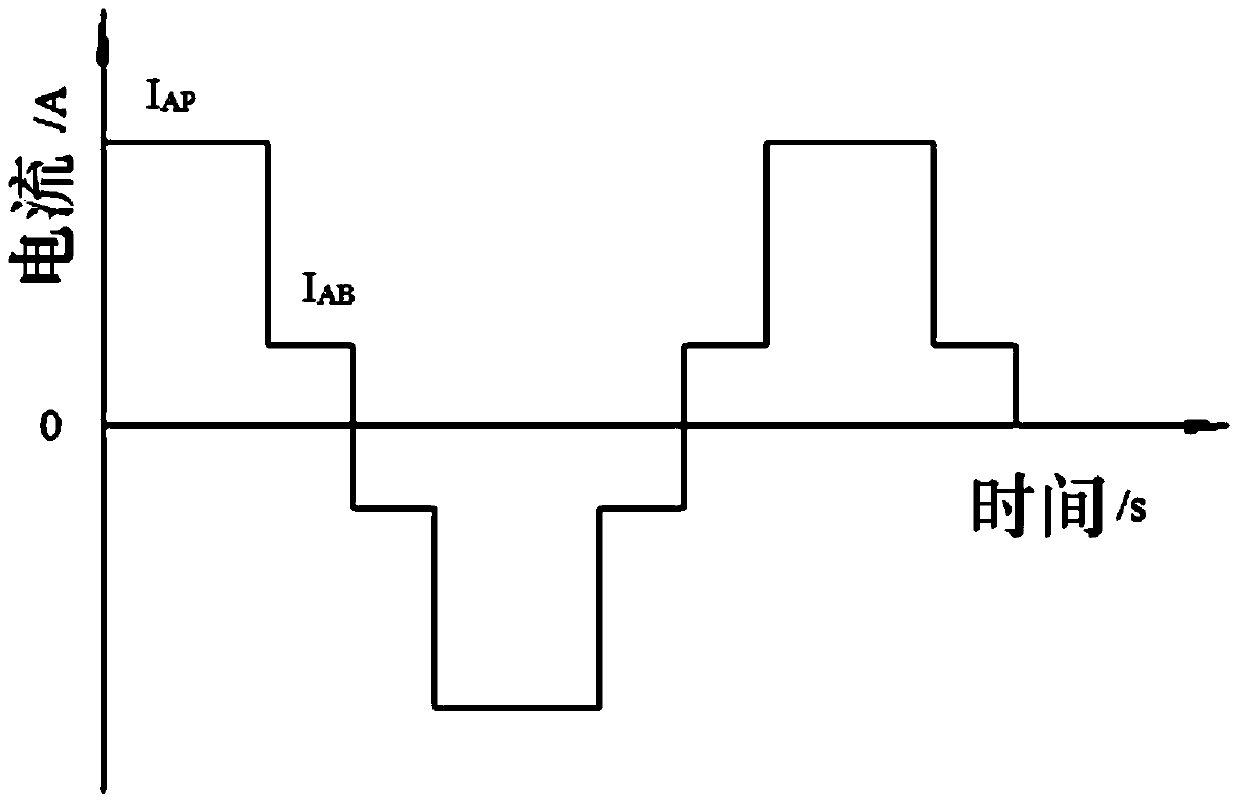

[0036] Use the wal...

Embodiment 2

[0042] A narrow gap welding method at the vertical seam position of a liquid natural gas storage tank, the steps are as described in Example 1, the difference is that the wire feeding speed is 300cm / min, the arc voltage is 12V, the welding wire preheating current is 70A, and the welding speed is 6cm / min. min, the heat input is controlled below 33KJ / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com