Sound absorbing material with tail gas clean-up function and preparation method thereof

A technology for sound-absorbing materials and exhaust gas purification, applied in the field of sound-absorbing materials, can solve the problems of lack of sound-absorbing effect, scattering of sound-absorbing materials, environmental pollution, etc., and achieve the effects of less acid exhaust gas corrosion, improved sound-absorbing effect, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

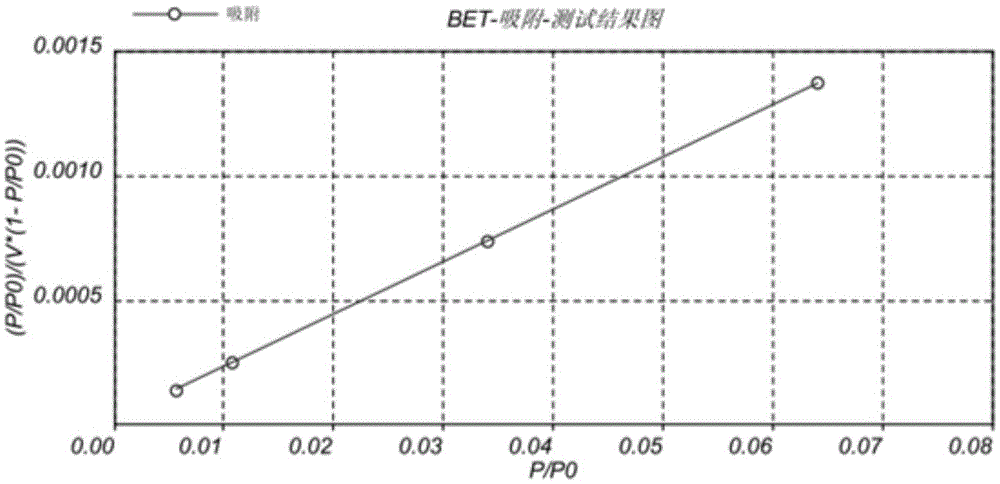

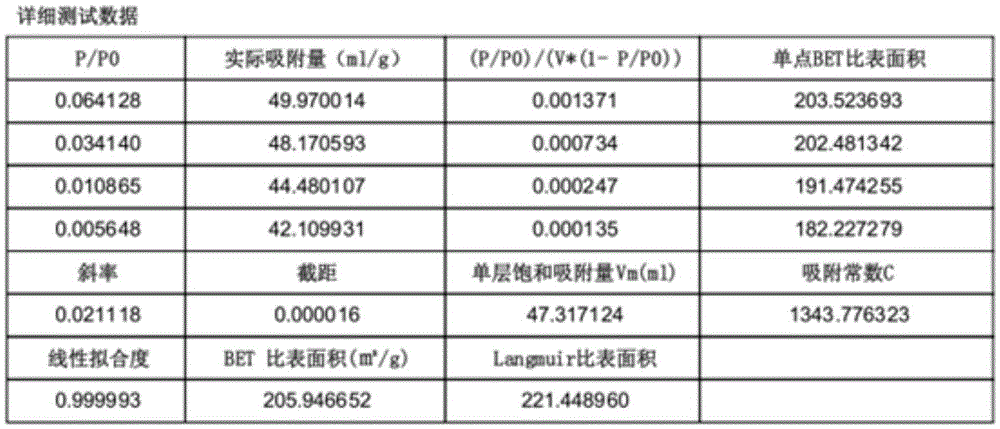

Image

Examples

Embodiment 1

[0040] First, comb the continuous basalt fiber into fiber bundles, wash off the sizing agent on the surface with acetone, then rinse the acetone with water and dry it for later use;

[0041] Then, the washed continuous basalt fiber was acid-etched in 1.0 mol / L HCl solution at a temperature of 60° C. for 2 hours, and then rinsed with hydrochloric acid.

[0042] Finally, the acid-etched continuous basalt fiber was calcined at 350° C. for 4 hours, and the temperature was lowered to obtain activated continuous basalt fiber, that is, the sound-absorbing material with exhaust gas purification function.

[0043] The specific properties of the sound-absorbing material with tail gas purification function obtained in this embodiment are shown in Table 1:

[0044] Table 1 Performance parameters of sound-absorbing materials with exhaust gas purification function

[0045] project

Embodiment 2

[0047] First, comb the continuous basalt fiber into fiber bundles, wash off the sizing agent on the surface with styrene, then rinse the styrene with water and dry it for later use;

[0048] Then, wash the continuous basalt fiber at a concentration of 0.5mol / LH 2 SO 4 After acid etching for 1.5 hours at a temperature of 60°C in the solution, rinse the sulfuric acid with water

[0049] Finally, the acid-etched continuous basalt fiber was calcined at 400° C. for 3.5 hours, and the temperature was lowered to obtain activated continuous basalt fiber, that is, the sound-absorbing material with exhaust gas purification function.

Embodiment 3

[0051] First, comb the continuous basalt fiber into fiber bundles, wash off the sizing agent on the surface with acetone, then rinse the acetone with water and dry it for later use;

[0052] Then, the washed continuous basalt fiber was acid-etched in 2.0 mol / L acetic acid solution at a temperature of 60° C. for 3 hours, and then rinsed with acetic acid with water.

[0053] Finally, the acid-etched continuous basalt fiber was calcined at 300° C. for 5 hours, and the temperature was lowered to obtain activated continuous basalt fiber, that is, the sound-absorbing material with exhaust gas purification function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com