Starch capsule filled with freeze-dried meat product

A technology for starch capsules and meat products, applied in the fields of freeze-dried food and starch capsules, can solve the problems of cumbersome, easy to breed bacteria, loss of nutrients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

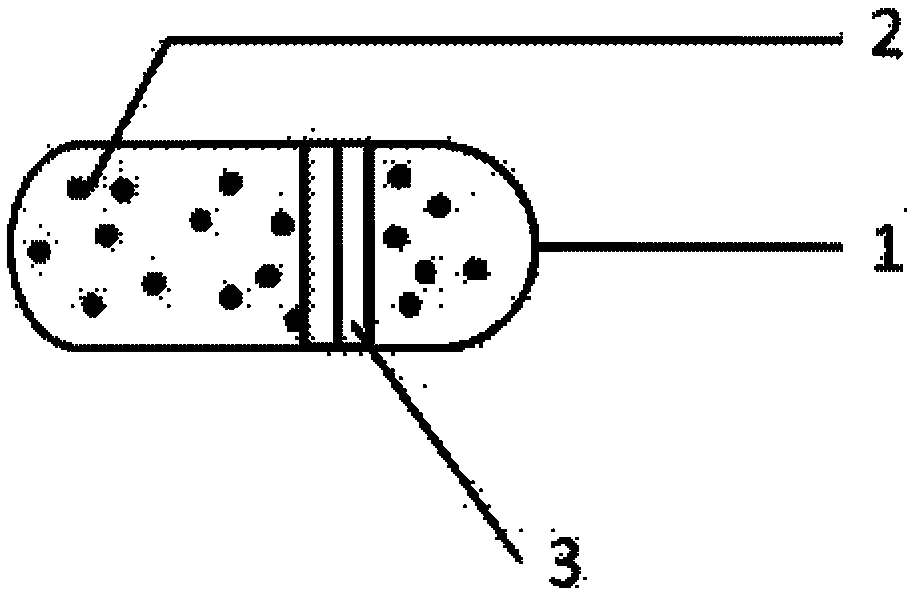

[0031] Embodiment 1: as shown in the figure, a kind of capsule of freeze-dried meat product of the present invention has been filled, it is characterized in that, it has the hollow starch capsule 1 that fits, and solid freeze-dried meat product 2 is loaded into the hollow starch capsule 1 Inside, and coat a layer of starch film 3 at the lock. Screen and select fresh meat products for quality selection; rinse the selected meat products 3~5 times with clean water to wash away the remaining blood stains; send the cleaned fresh meat products into a slicer for slice processing, The thickness of the meat slices is 2~5mm, which is convenient for freeze-drying; the cut meat products are frozen at 5°C below the eutectic point, and the freezing time is 3 hours. After the meat slices are completely frozen, move them into a freeze dryer for freeze-drying. The temperature is -30°C~-45°C, the freeze-drying time is 22 hours, the temperature is increased gradually for 8 hours, the final analy...

Embodiment 2

[0033] Embodiment 2: adopt the same method as embodiment 1, the difference is that there is no starch film coated at the closure.

[0034] Check the capsule of embodiment 1,2 respectively in 24 months, the change situation of coliform group and moisture.

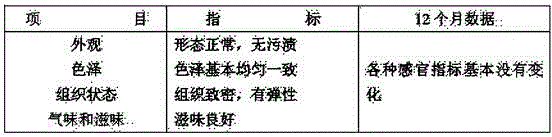

[0035] Table 2 Embodiment 1 other part related index detection data

[0036]

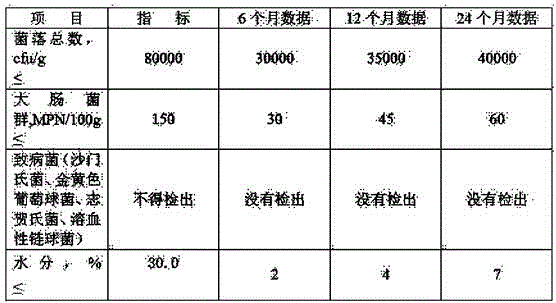

[0037] Table 3 embodiment 2 part related index detection data

[0038]

[0039] When cooking soup, take several capsules filled with freeze-dried meat products, and put the capsules 1 in hot soup to quickly swell and release the meat products. Because the invention has a nested starch hollow capsule 1 structure, the taste and nutritional content of meat products are retained, and the shelf life is extended. In addition, the problem of accurately controlling the amount of meat products added by filling freeze-dried meat products into starch hollow capsules is convenient. Carry and store.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com