Process for improving recovery rate of solvent in mother liquid

A technology of recovery rate and mother liquor, applied in the chemical industry, can solve problems such as restricting production costs, and achieve the effects of increasing output rate, saving production costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

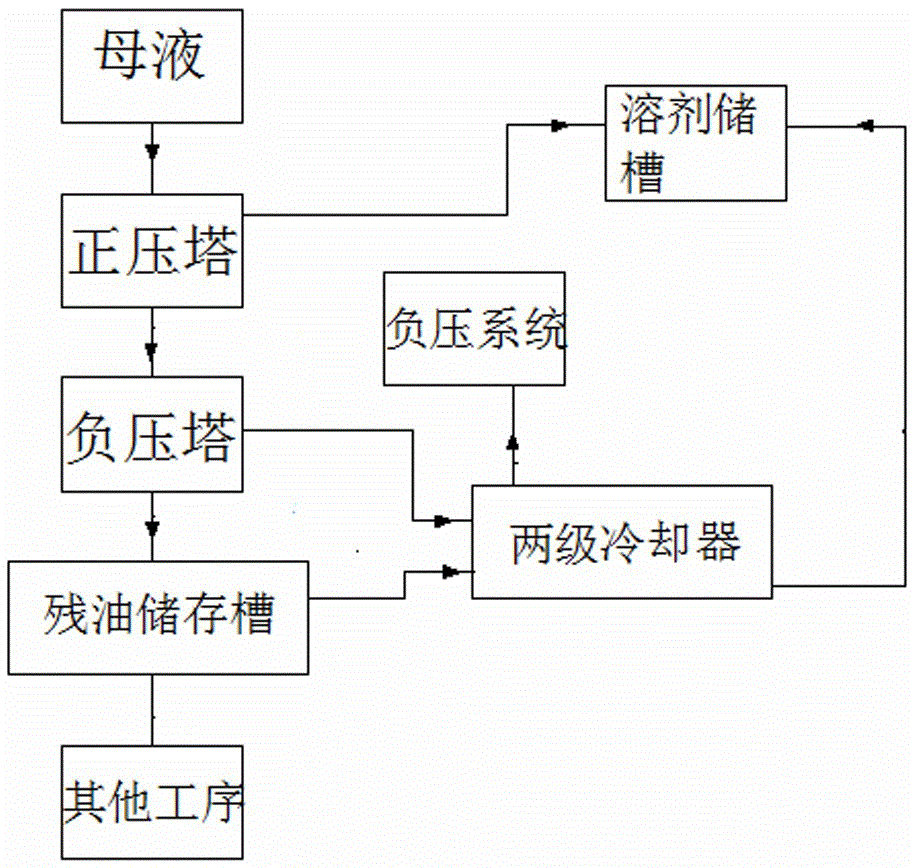

[0035] The mother liquor produced by washing carbazole is used as the raw material of the solvent oil recovery system. The pump is used to feed the 1# solvent oil recovery tower (structured corrugated packing tower). The fraction at the bottom of the tower is heated by the pump through the tube furnace and then returns to the tower. The oil temperature at the outlet of the tube furnace is controlled at 300 °C. The temperature at the top of the tower is controlled at 110-130°C, the pressure is 10-20Kpa, and the purity of the extracted solvent oil is 99%. After being cooled by a 20°C circulating water cooler, it enters the solvent oil storage tank. The residual oil containing solvent oil ≤ 2% is extracted from the bottom of the tower, and fed to the 2# negative pressure tower (structured corrugated packing tower).

[0036] The heat source is provided by superheated steam at the bottom of the tower, the temperature at the top is controlled at 80-100°C, and the pressure is control...

Embodiment 2

[0040] The mother liquor produced by washing the refined anthracene is used as the raw material of the solvent oil recovery system. The pump is used to feed the 1# solvent oil recovery tower (structured corrugated packing tower). The fraction at the bottom of the tower is heated by the pump through the tube furnace and then returns to the tower. The oil temperature at the outlet of the tube furnace is controlled at 300 °C. The temperature at the top of the tower is controlled at 110-130°C, the pressure is 10-20Kpa, and the purity of the extracted solvent oil is 99%. After being cooled by a 20°C circulating water cooler, it enters the solvent oil storage tank. The residual oil containing solvent oil ≤ 2% is extracted from the bottom of the tower, and fed to the 2# negative pressure tower (structured corrugated packing tower).

[0041] The heat source is provided by superheated steam at the bottom of the tower, the temperature at the top is controlled at 80-100°C, and the pressu...

Embodiment 3

[0045] The mother liquor produced by washing carbazole is used as the raw material of the solvent oil recovery system. The pump is used to feed the 1# solvent oil recovery tower (structured corrugated packing tower). The fraction at the bottom of the tower is heated by the pump through the tube furnace and then returns to the tower. The oil temperature at the outlet of the tube furnace is controlled at 280 °C. The temperature at the top of the tower is controlled at 110-130°C, the pressure is 10-20Kpa, and the purity of the extracted solvent oil is 99%. After being cooled by a 20°C circulating water cooler, it enters the solvent oil storage tank. The residual oil containing solvent oil ≤ 3% is extracted from the bottom of the tower, and fed to the 2# negative pressure tower (structured corrugated packing tower).

[0046] The heat source is provided by superheated steam at the bottom of the tower, the temperature at the top is controlled at 90-100°C, and the pressure is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com