A diamond grinding disc for polishing artificial zirconium gemstones

A technology of zircon gemstones and diamonds, which is applied in the field of preparation of resin matrix diamond polishing discs, can solve the problems of low effective pertinence of diamond polishing discs, uneven distribution of diamond particles, and difficulty in manufacturing ultra-fine particle sizes, so as to achieve fine grinding and polishing efficiency High, good brightness quality, low scrap rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

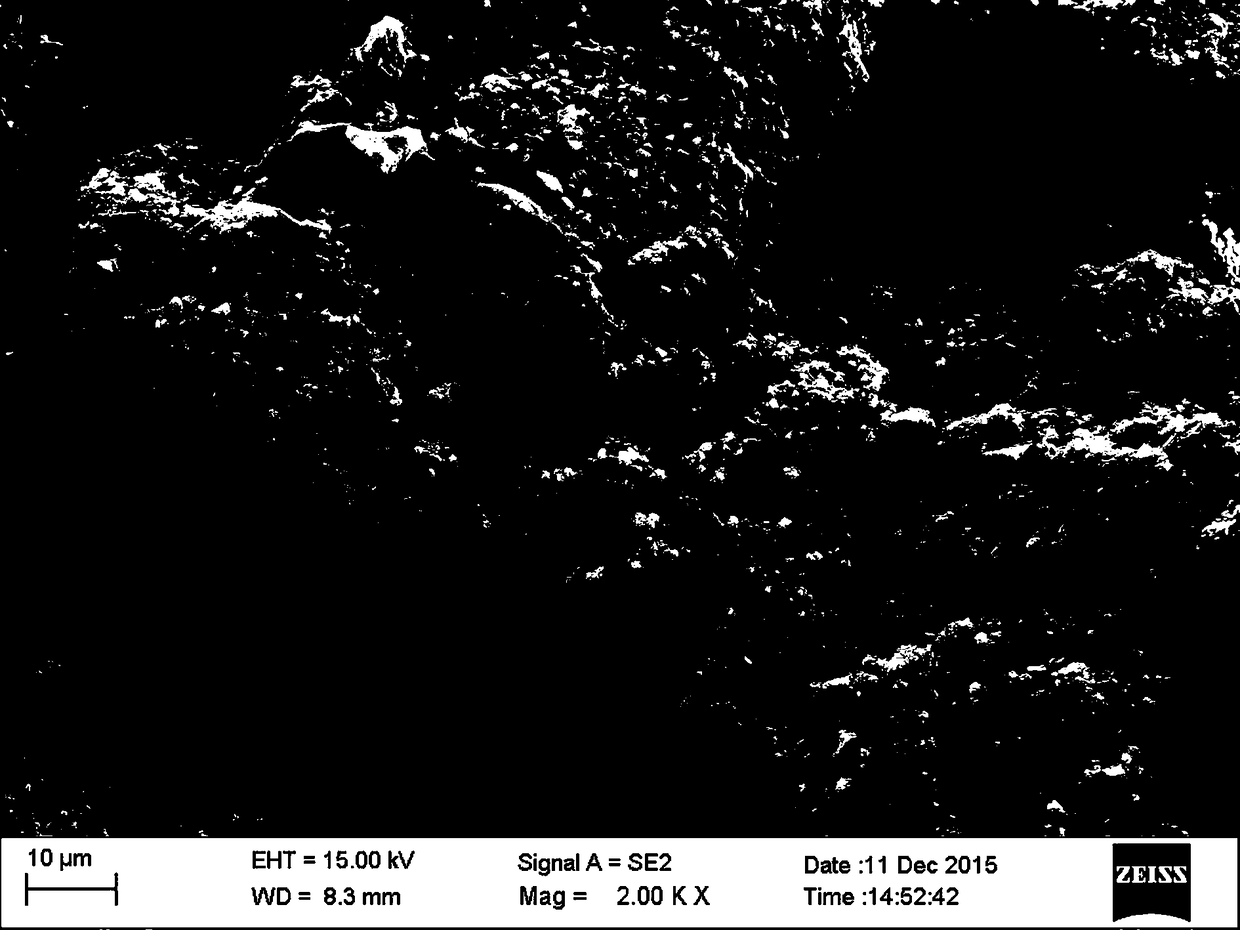

Image

Examples

Embodiment 1

[0024] A diamond grinding disc for polishing artificial zircon gemstones has a disc surface diameter of 400 mm and a thickness of 55 mm, and its preparation materials include the following components according to mass percentage:

[0025] Diamond 75%;

[0026] Hexagonal boron nitride nanosheets 4%;

[0027] Phenolic resin powder 16.3%;

[0029] Zirconia 2%;

[0030] Filler zirconium corundum 0.7%.

[0031] Among them, the particle size of abrasive diamond is not greater than 1 micron, the particle size of hexagonal boron nitride nanosheets is not greater than 200 nanometers, the particle size of resin powder is not greater than 10 microns; the particle size of cerium oxide is not greater than 5 microns; the particle size of zirconia is not greater than 5 microns Micron; particle size of filler zirconium corundum is not more than 5 microns.

[0032] The surface roughness of the zirconium gemstone after polishing can reach 10-35 nanometers for the ...

Embodiment 2

[0034] A diamond grinding disc for polishing artificial zircon gemstones has a disc surface diameter of 400 mm and a thickness of 55 mm, and its preparation materials include the following components according to mass percentage:

[0035] Diamond 80%;

[0036] Hexagonal boron nitride nanosheets 3%;

[0037] Phenolic resin powder 13.3%;

[0038] Cerium oxide 1.5%;

[0039] Zirconia 1.5%;

[0040] Filler zirconium corundum 0.7%.

[0041] Among them, the particle size of abrasive diamond is not greater than 1 micron, the particle size of hexagonal boron nitride nanosheets is not greater than 200 nanometers, the particle size of resin powder is not greater than 10 microns; the particle size of cerium oxide is not greater than 5 microns; the particle size of zirconia is not greater than 5 microns Micron; particle size of filler zirconium corundum is not more than 5 microns.

[0042] The surface roughness of the zircon gemstone after polishing can reach 15-38 nanometers for the...

Embodiment 3

[0044] A diamond grinding disc for polishing artificial zircon gemstones has a disc surface diameter of 400 mm and a thickness of 55 mm, and its preparation materials include the following components according to mass percentage:

[0045] Diamond 80%;

[0046] Hexagonal boron nitride nanosheets 4%;

[0047] Phenolic resin powder 11.3%;

[0048] Cerium oxide at 2%;

[0049] Zirconia 2%;

[0050] Filler zirconium corundum 0.7%.

[0051] Among them, the particle size of abrasive diamond is not greater than 1 micron, the particle size of hexagonal boron nitride nanosheets is not greater than 200 nanometers, the particle size of resin powder is not greater than 10 microns; the particle size of cerium oxide is not greater than 5 microns; the particle size of zirconia particles is not greater than 5 microns ; The particle size of the filler zirconium corundum is not greater than 5 microns.

[0052] The surface roughness of the zirconium gemstone after polishing can reach 16-40 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com