Preparation method of small-crystalline-grain ZSM-22 (Zeolite Socony Mobil-22) molecular sieve

A technology of ZSM-22 and molecular sieve, which is applied in the field of TON topological structure, can solve the problems of increased catalyst activity, organic solvent and acid-base solution increase waste liquid treatment process and difficulty, and high treatment cost, so as to achieve high catalytic activity and good catalytic application Prospects, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

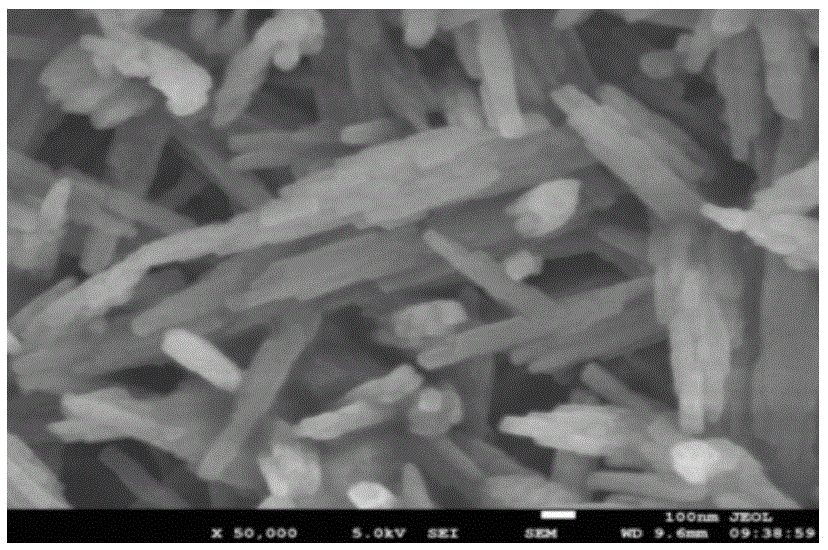

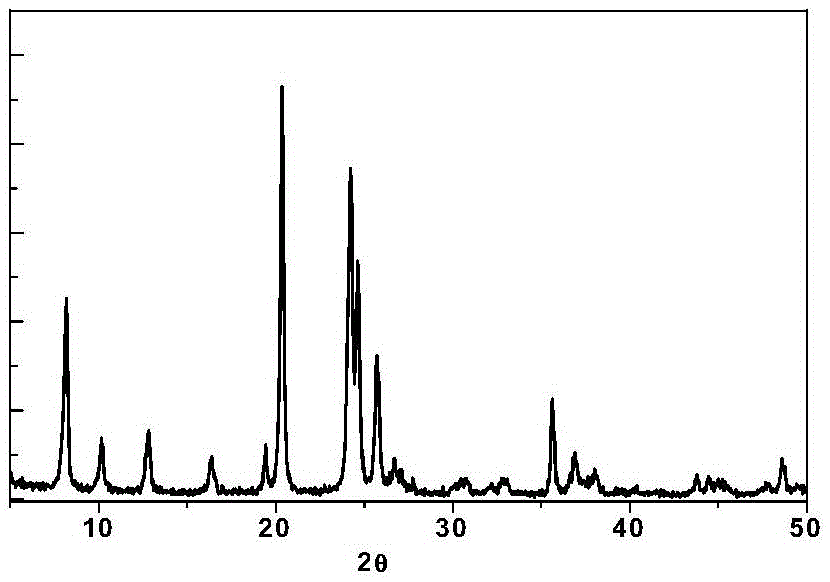

[0027] First, mix the raw materials uniformly according to the following molar ratio, silica sol (in the form of SiO 2 In terms of): aluminum sulfate (as Al 2 o 3 Total): 1,6-hexanediamine: potassium hydroxide: deionized water = 1: 0.011: 0.005: 0.29: 40. Then, add 0.5g activated carbon (with SiO 2 The mass ratio is 0.06:1), adding ZSM-22 powder (addition amount is 10% of SiO2 mass). Stir well. Finally, the mixed raw materials were transferred to a stainless steel reaction kettle, and dynamically crystallized at 160°C for 48 hours. The product was filtered, washed, dried, and roasted at 550°C for 16 hours to obtain ZSM-22 molecular sieve with small grains, the grain length was ~200nm, and the product The XRD and SEM spectra are shown in figure 2 .

Embodiment 2-8

[0029] The specific proportions of ingredients and crystallization conditions are shown in Table 1, and the specific preparation process is the same as in Example 1. Wherein, the seed crystal added in embodiment 2 is the stock solution containing ZSM-22 seed crystal, and the addition amount is SiO 2 0.1% of mass. The seed crystal added in embodiment 3 is the original powder of ZSM-22, and the addition amount is SiO 2 10% of the mass. Examples 4-9, no seed crystals were added.

Embodiment 4-9

[0029] The specific proportions of ingredients and crystallization conditions are shown in Table 1, and the specific preparation process is the same as in Example 1. Wherein, the seed crystal added in embodiment 2 is the stock solution containing ZSM-22 seed crystal, and the addition amount is SiO 2 0.1% of mass. The seed crystal added in embodiment 3 is the original powder of ZSM-22, and the addition amount is SiO 2 10% of the mass. Examples 4-9, no seed crystals were added.

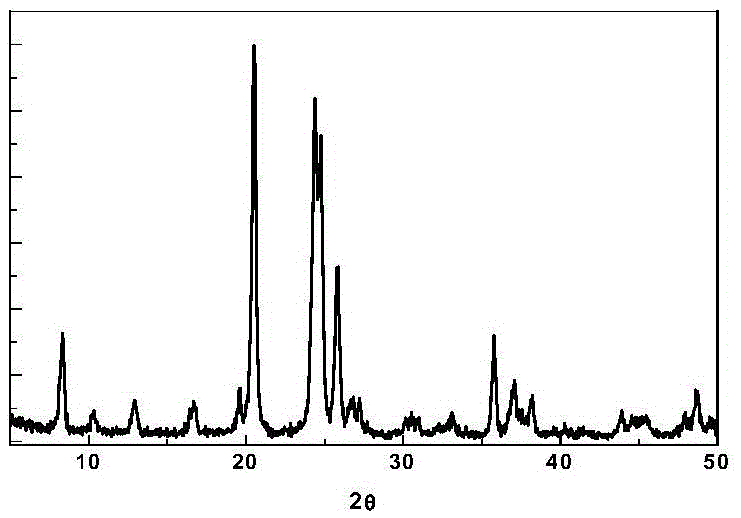

[0030] The synthetic samples were analyzed by XRD, and the data results were compared with figure 1 close, indicating that the synthesized product is a high-purity ZSM-22 molecular sieve. SEM analysis of the synthesized samples shows that the products are all small-grained molecular sieves with a length ≦220nm.

[0031] Table 1 Molecular sieve synthesis ingredients and crystallization, roasting conditions

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com