Food waste oil removing treatment method

A technology for food waste and oil treatment, applied in filtration treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of low equipment cost and high operating cost, reduce operating cost, improve processing capacity, and improve reaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

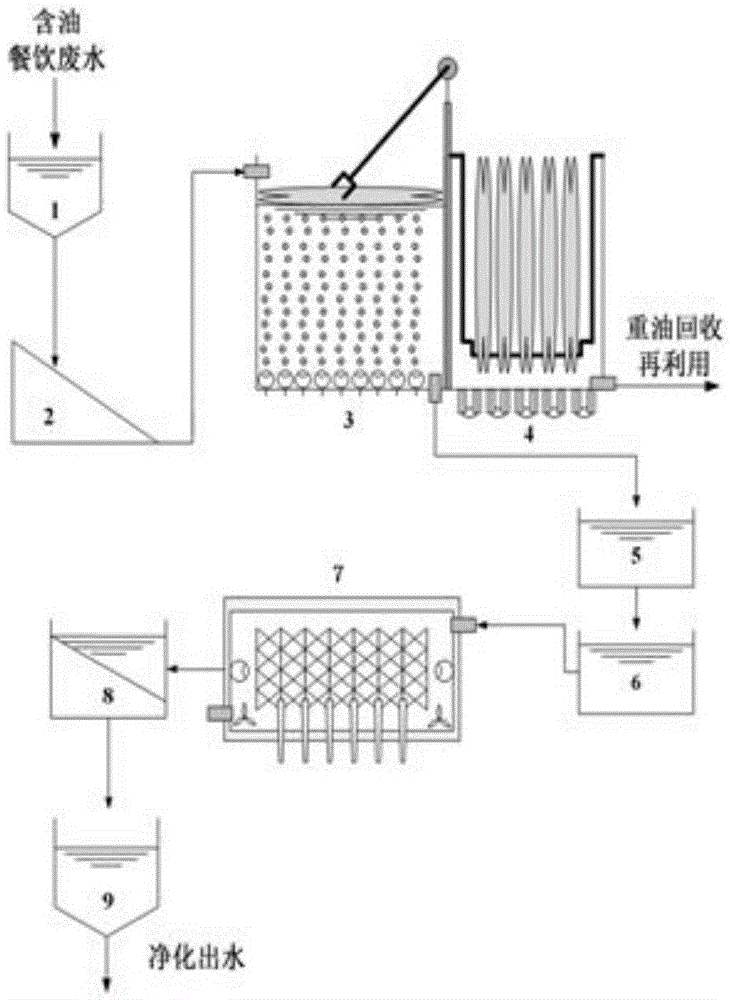

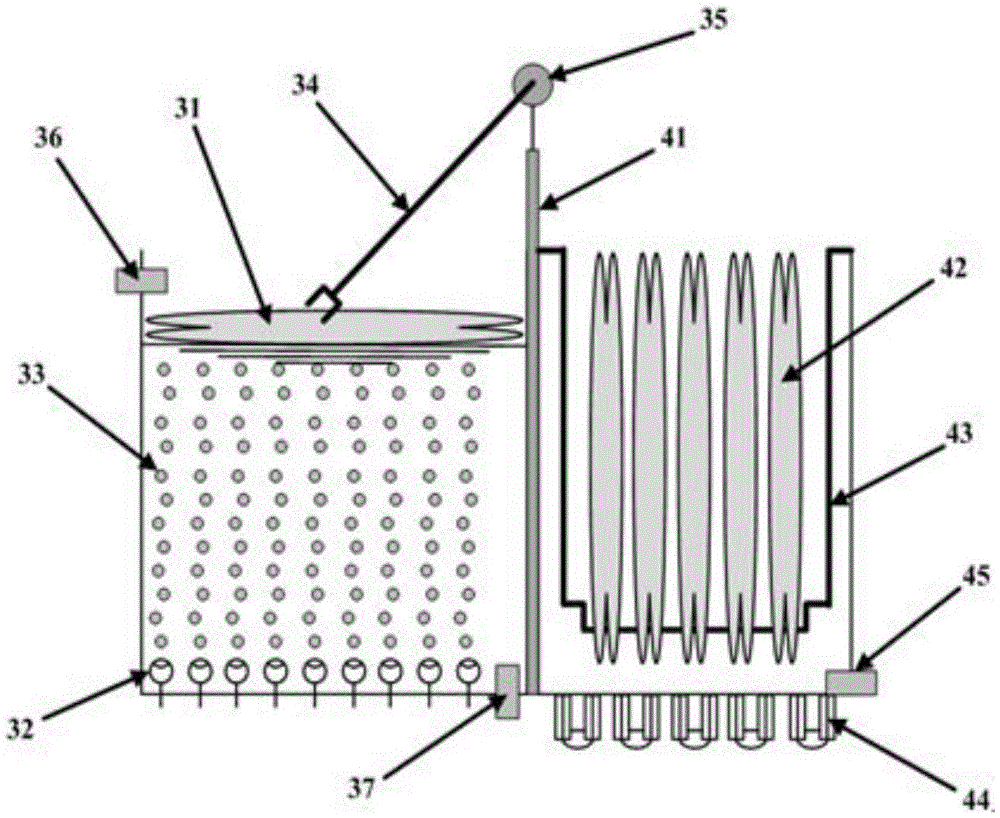

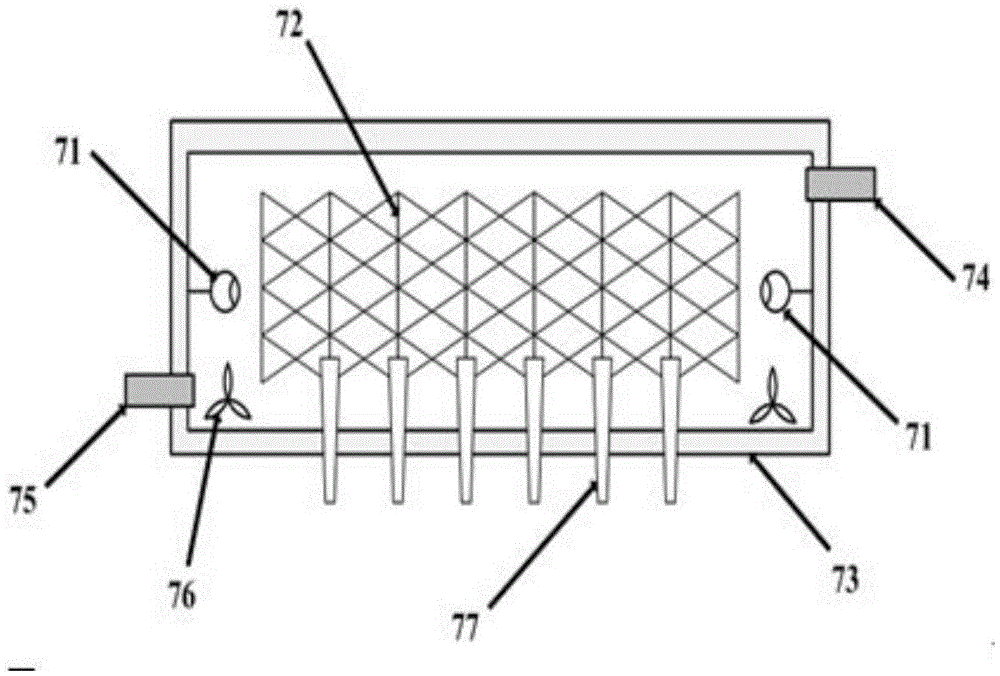

[0027] Attached below Figure 1-3 Embodiments of the present invention are described in detail:

[0028] Catering waste degreasing treatment method, the food waste is first filtered through the coarse grid and then enters the pretreatment pool, the water-containing food waste is coarsely filtered through the coarse grid, and the large-diameter solid matter in the garbage is removed, and then the pH value is adjusted to 3- 5. Add a certain amount of compound flocculant, first stir rapidly at 400r / min for 3min, then adjust the stirring speed to 60r / min, stir slowly for 20min, let stand for a period of 30min and then settle and stratify.

[0029] Such as figure 1As shown, the upper liquid enters the buffer pool through the waste water pipeline, where it is collected and stabilized, and the outlet of the buffer pool 1 is connected to the fine grid 2 through the waste water pipeline, where the small-diameter solid matter in the food waste is removed, and the fine grid The outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com