Method for synthesizing lithium-ion battery cathode material lithium manganese iron phosphate by microwave method

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of complex process, poor performance and high cost, and achieve uniform structure, good performance and good product performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

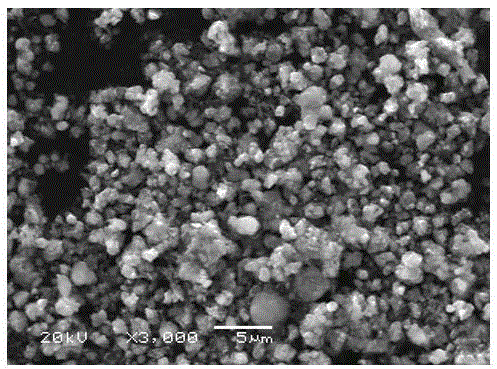

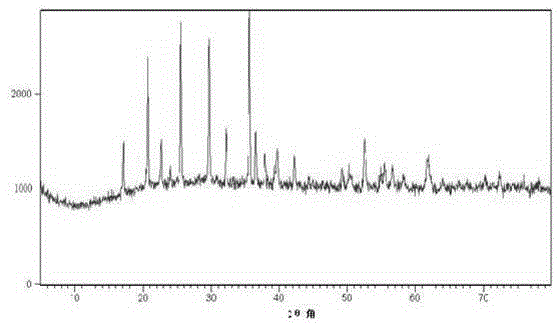

Image

Examples

Embodiment 1

[0035] Embodiment 1: A kind of microwave method synthesis LiMn of lithium-ion battery cathode material 0.7 Fe 0.3 PO 4 method, including the following steps:

[0036] (1) Will Li 2 CO 3 , Fe 2 o 3 1. Li, Fe and P in phosphoric acid are respectively measured according to the molar ratio of 1:0.95:0.98, and pure water is added to phosphoric acid to prepare a 70-75wt% phosphoric acid solution; then 8-12% of its weight is added to the phosphoric acid solution citric acid, stir well, prepare the aqueous solution of citric acid and phosphoric acid;

[0037] (2) Will Li 2 CO 3 Slowly added to the aqueous solution of citric acid and phosphoric acid, stirred evenly, and then slowly added Fe 2 o 3 , stir evenly to obtain a paste mixture, and age for 20 to 25 hours;

[0038] (3) Put the aged paste mixture in a non-metal container, put it into a closed microwave oven with a power of 20-25KW, use microwaves to heat up to 200-230°C at a rate of 3-8°C per minute, and then Maintai...

Embodiment 2

[0045] Embodiment 2: A kind of microwave method synthesis LiMn of lithium-ion battery cathode material 0.7 Fe 0.3 PO 4 method, including the following steps:

[0046] (1) Will Li 2 CO 3 , Fe 2 o 3 1. Li, Fe, and P in phosphoric acid are respectively measured at a molar ratio of 1:0.98:1.02, and pure water is added to phosphoric acid to prepare a 70% phosphoric acid solution; then 10% of its weight in citric acid is added to the phosphoric acid solution, Stir evenly to prepare an aqueous solution of citric acid and phosphoric acid;

[0047] (2) Will Li 2 CO 3 Slowly added to the aqueous solution of citric acid and phosphoric acid, stirred evenly, and then slowly added Fe 2 o 3 , stir evenly to obtain a paste mixture, and age for 20 hours;

[0048] (3) Put the aged paste mixture in a graphite crucible, put it into a closed microwave oven with a power of 20KW, use microwaves to raise the temperature to 210°C at a rate of 5°C per minute, and keep it at this temperature ...

Embodiment 3

[0055] Embodiment 3: A kind of microwave method synthesis LiMn of positive electrode material of lithium ion battery 0.7 Fe 0.3 PO 4 method, including the following steps:

[0056] (1) Will Li 2 CO 3 , Fe 2 o 3 1. Li, Fe, and P in phosphoric acid are respectively measured at a molar ratio of 1:0.96:1, and pure water is added to phosphoric acid to prepare a 75% phosphoric acid solution; then 12% citric acid by weight is added to the phosphoric acid solution, and stirred Evenly, the aqueous solution of citric acid and phosphoric acid is prepared;

[0057] (2) Will Li 2 CO 3 Slowly added to the aqueous solution of citric acid and phosphoric acid, stirred evenly, and then slowly added Fe 2 o 3 , stir evenly to obtain a paste mixture, and age for 25 hours;

[0058] (3) Put the aged paste mixture in a non-metal container, put it into a closed microwave oven with a power of 25KW, use microwaves to raise the temperature to 230°C at a rate of 8°C per minute, and keep it at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com