A kind of resin used in correction fluid and its chemical synthesis method and a kind of correction fluid

A technology of chemical synthesis and correction fluid, applied in the field of materials, can solve the problems of layering phenomenon, pen dragging phenomenon, and the hardness of correction fluid does not meet the requirements, and achieve the effect of stable reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

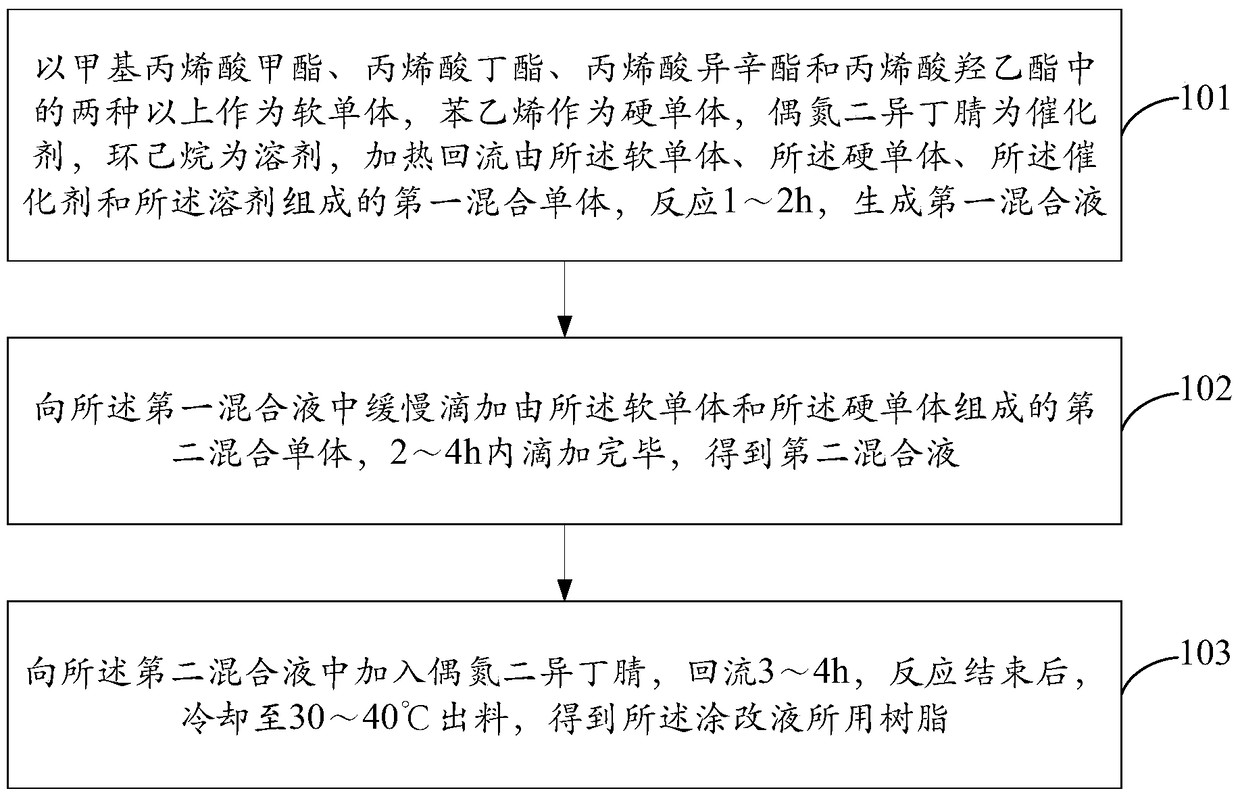

[0025] refer to figure 1 , showing a flow chart of a chemical synthesis method for a resin used in correction fluid described in an embodiment of the present invention, by figure 1 It can be seen that the chemical synthesis method comprises the following steps:

[0026] In step 101, two or more of methyl methacrylate, butyl acrylate, isooctyl acrylate and hydroxyethyl acrylate are used as soft monomers, styrene is used as hard monomers, and azobisisobutyronitrile is used as a catalyst. Hexane is used as a solvent, and the first mixed monomer composed of the soft monomer, the hard monomer, the catalyst and the solvent is heated and refluxed to react to form a first mixed liquid.

[0027] In the first mixed monomer, the mass ratio of the methyl methacrylate to the styrene is 0.117-0.162, and the mass ratio of the butyl acrylate to the styrene is 0.157-0.244, so The mass ratio of the hydroxyethyl acrylate to the styrene is 0.08 to 0.139, the mass ratio of the isooctyl acrylate ...

Embodiment 1

[0046]Add 21 kilograms of methyl methacrylate, 44 kilograms of butyl acrylate, 109 kilograms of isooctyl acrylate, 180 kilograms of styrene, 500 kilograms of cyclohexane, and 3.8 kilograms of azobisisobutyronitrile in a 2000L reactor, and heat to 90 The reflux operation was carried out at about ℃, and the reaction was carried out for 2 hours.

[0047] Slowly add 18 kg of methyl methacrylate, 40 kg of butyl acrylate, 101 kg of isooctyl acrylate, and 180 kg of styrene into the mixed monomers dropwise, and the dripping is completed within 2 hours.

[0048] Add 3 kg of azobisisobutyronitrile, heat to about 90°C for reflux operation, and react for 4 hours. After the reaction is completed, cool to 35-40°C and discharge to obtain the resin for correction fluid.

Embodiment 2

[0050] Add 22 kg of hydroxyethyl acrylate, 150 kg of isooctyl acrylate, 200 kg of styrene, 500 kg of cyclohexane, and 4.5 kg of azobisisobutyronitrile into a 2000L reactor, heat it to about 95°C for reflux operation, and react 1h.

[0051] Slowly add 20 kg of mixed monomers hydroxyethyl acrylate, 142 kg of isooctyl acrylate, and 217 kg of styrene mixed monomers, and drop them within 4 hours.

[0052] Add 4 kg of azobisisobutyronitrile, heat to about 95°C for reflux operation, and react for 3 hours. After the reaction is completed, cool to 30-35°C and discharge to obtain the resin for correction fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com