Method for extracting graphene quantum dots from coffee-ground solid waste

A technology of graphene quantum dots and solid waste, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problems of cumbersome synthesis steps, use, and difficult preparation of gram quantities, and achieve simple process steps and mild reactions , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

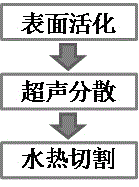

Method used

Image

Examples

Embodiment 1

[0022] Wash the recovered lightly roasted coffee grounds, weigh 1 g and add it to 80 ml of 0.1 mol / L dilute hydrochloric acid, stir and sonicate for 20 h. After the ultrasound stops, filter and wash the coffee grounds repeatedly with deionized water until the pH of the filtrate is about 7. Ultrasonic disperse the washed coffee grounds in 100ml of distilled water, add 10ml of ammonia water and 40ml of hydrazine hydrate mixture (the pH of the solution is not lower than 12) while stirring, and immediately put it into a polytetrafluoroethylene reaction kettle. o C temperature reaction 20h. Take it out after natural cooling, and filter it with a 25nm filter membrane to obtain a dark brown filtrate. The filtered solution is transferred to a dialysis bag for dialysis, and the solution is put into an oven at 120 oC After drying, brown-gray graphene quantum dot powder is finally obtained.

Embodiment 2

[0024] Wash the recovered moderately roasted coffee grounds, weigh 1 g and add it to 80 ml of 0.05 mol / L dilute hydrochloric acid, stir and sonicate for 10 h. After the ultrasound stops, filter and wash the coffee grounds repeatedly with deionized water until the pH of the filtrate is about 7. Ultrasonic disperse the washed coffee grounds in 100ml of distilled water, add 5ml of ammonia water and 20ml of hydrazine hydrate mixture (the pH of the solution is not lower than 12) while stirring, and immediately put it into a polytetrafluoroethylene reaction kettle. o C temperature reaction 10h. Take it out after natural cooling, and filter it with a 25nm filter membrane to obtain a dark brown filtrate. The filtered solution is transferred to a dialysis bag for dialysis, and the solution is put into an oven at 120 oC After drying, brown-gray graphene quantum dot powder is finally obtained.

Embodiment 3

[0026] Wash the recovered deep-roasted coffee grounds, weigh 1 g and add it to 80 ml of 0.1 mol / L dilute hydrochloric acid, stir and sonicate for 2 hours. After the ultrasound stops, filter and wash the coffee grounds repeatedly with deionized water until the pH of the filtrate is about 7. Ultrasonic disperse the washed coffee grounds solid in 100ml of distilled water, add 1ml of ammonia water and 5ml of hydrazine hydrate mixture (the pH of the solution is not lower than 12) while stirring, and immediately put it into a polytetrafluoroethylene reaction kettle, at 120 o C temperature reaction 5h. Take it out after natural cooling, and filter it with a 25nm filter membrane to obtain a dark brown filtrate. The filtered solution is transferred to a dialysis bag for dialysis, and the solution is put into an oven at 120 oC After drying, brown-gray graphene quantum dot powder is finally obtained.

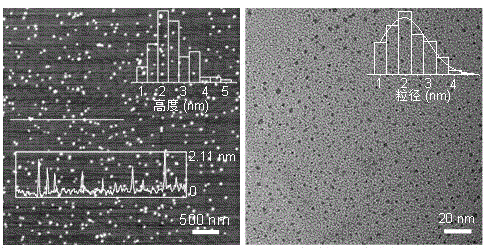

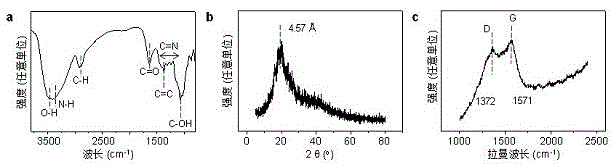

[0027] The sample prepared in the present embodiment is characterized through instr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com