Light hydrocarbon recycling system and method

A light hydrocarbon recovery and light hydrocarbon technology, which is applied to the recovery of liquid hydrocarbon mixtures, hydrocarbon distillation, and hydrocarbon oil treatment, can solve problems such as increased vaporization, high pressure in fractionation towers, and effects on the vacuum degree of vacuum fractionation towers. Effects of recycling rate, load reduction, and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

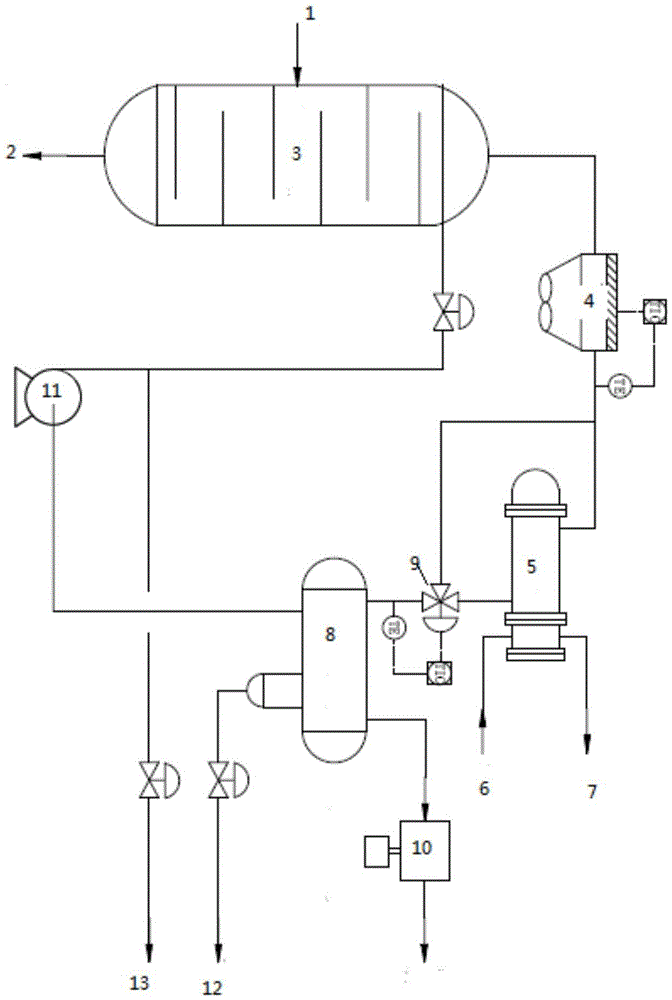

[0078] Prepare a light hydrocarbon recovery system, specifically: a plate type single overflow light hydrocarbon recovery tower, a variable angle adjustable air cooler connected to the top outlet of the plate type single overflow light hydrocarbon recovery tower, and a variable angle adjustable air cooler outlet The U-shaped shell-and-tube water cooler; the horizontal light hydrocarbon separator whose inlet is connected to the outlet of the U-shaped shell-and-tube water cooler; the reciprocating light hydrocarbon booster whose inlet is connected to the gas outlet of the horizontal light hydrocarbon separator, reciprocating The supercharger transports light hydrocarbons to the fuel gas pipeline network.

Embodiment 2

[0080] The above-mentioned light hydrocarbon recovery system is used in the white oil hydroisomerization system, the low oil fraction control temperature is 270°C, the low fraction oil entering the light hydrocarbon recovery tower is 24t / h, and the top temperature of the light hydrocarbon recovery tower is 160°C , the pressure is 0.2Mpa, after rectification, the gas phase part is condensed twice through the air cooler and water cooler to the light hydrocarbon separator through the outlet of the tower top, and the temperature of the air cooler is 85°C; the cooling water of the water cooler is 20°C; the gas-liquid separator The inlet temperature is 50°C; the dehydration boundary is 50%, the gas phase of the light hydrocarbon separator passes through the light hydrocarbon recovery device to obtain recovered light hydrocarbons, and the oil phase outlet of the light hydrocarbon separator is fine white oil. After calculation, the amount of light hydrocarbon recovered is 100NM 3 / h, ...

Embodiment 3

[0082] The above-mentioned light hydrocarbon recovery system is used in the white oil hydroisomerization system, the low oil fraction control temperature is 280°C, the low fraction oil entering the light hydrocarbon recovery tower is 24t / h, and the top temperature of the light hydrocarbon recovery tower is 170°C , the pressure is 0.25Mpa, after rectification, the gas phase part is condensed twice through the air cooler and water cooler through the outlet of the tower top to reach the gas-liquid separator, the temperature of the air cooler is 90°C; the cooling water of the water cooler is 20°C; the gas-liquid separator The inlet temperature is 60°C; the dehydration boundary is 50%, the gas phase of the light hydrocarbon separator passes through the light hydrocarbon recovery device to obtain recovered light hydrocarbons, and the oil phase outlet of the light hydrocarbon separator is fine white oil. After calculation, the amount of light hydrocarbon recovered is 240NM 3 / h, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com