Preparation method of silicon/carbon composite material applied to high-performance lithium ion battery anodes

A technology of lithium-ion batteries and carbon composite materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of silicon nanoparticle graphene sheet stacking, etc., to improve cycle stability, avoid direct contact, increase evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) NaF (0.5molL -1 ) configuration: Weigh 4.2g NaF and dissolve it in 200ml water to obtain.

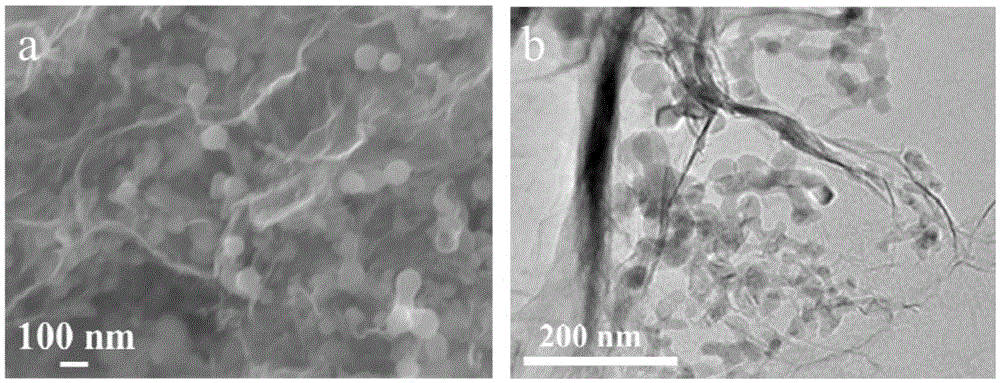

[0036] 2) NaF-silicon / graphene oxide composite material: Weigh 300 mg of silicon nanoparticles and add them to a mixed solvent of absolute ethanol: water = 1:2 (volume ratio), after ultrasonication for 30 minutes, the ultrasonic power is 900 W, and then dropwise Add the aqueous sol (5mg / L) containing 270mg graphene oxide, finally add the NaF solution of 0.285ml, ultrasonic 60min, ultrasonic power is 300W; Namely obtain the mixed solution of NaF-silicon / graphene oxide composite material.

[0037] 3) Add the mixed solution obtained in step (2) into an ethanol solution of 889 mg of alcohol-soluble phenolic resin (concentration: 5 g / L), place it in a water bath at 50° C., and heat for 24 hours;

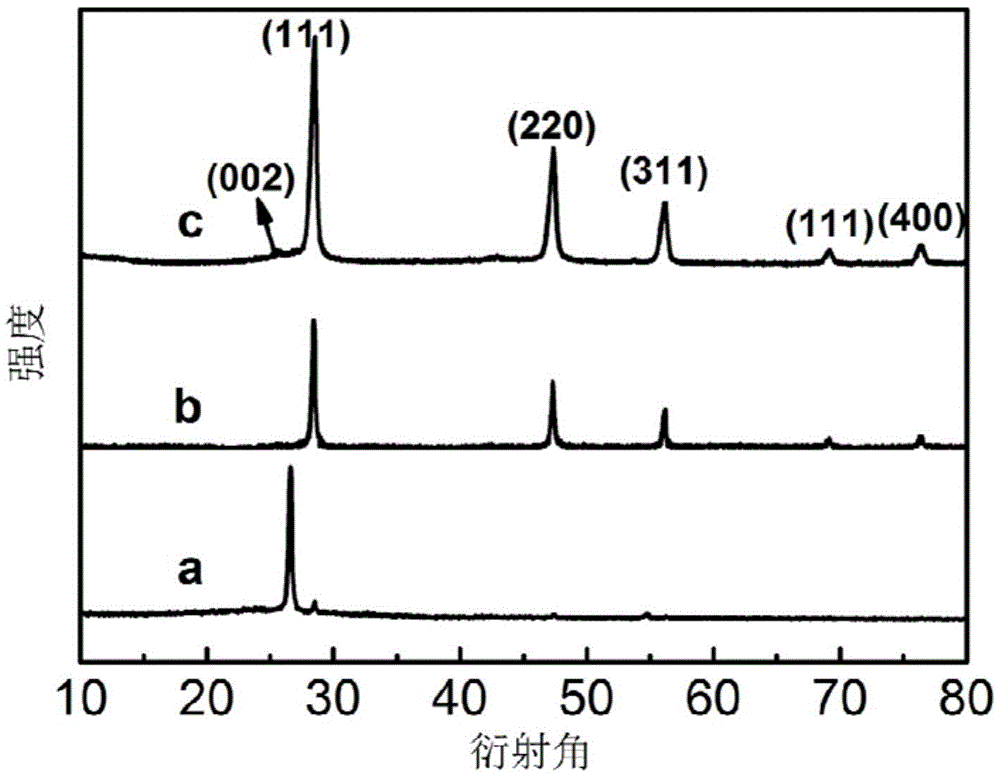

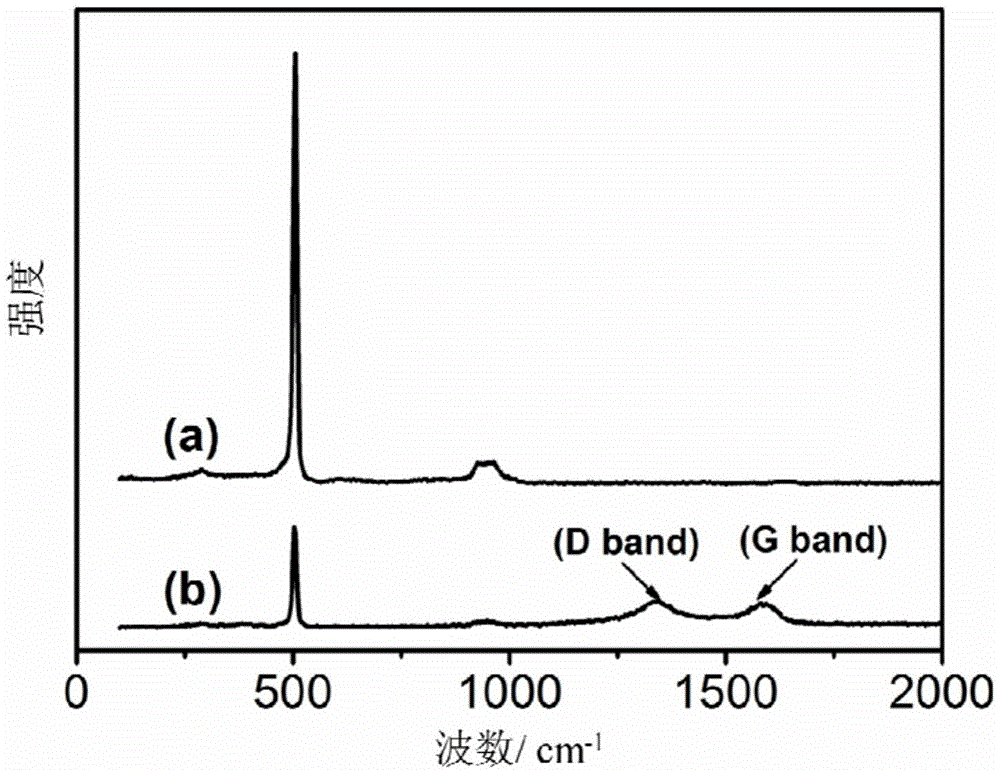

[0038] 4) The sample prepared in step (3) was raised to 700° C. at a heating rate of 7 minutes under an argon atmosphere, and kept at a constant temperature for 2 hours; 97 ml of hydrofl...

Embodiment 2

[0041] 1) NaF (0.5molL -1 ) configuration: Weigh 4.2g NaF and dissolve it in 200ml water to obtain.

[0042] 2) Mixed solution of NaF-silicon / graphene oxide composite material: Weigh 400 mg of silicon nanoparticles and add them to a mixed solvent of absolute ethanol / water = 1:1. Add the aqueous sol (2mg / L) containing 50mg graphene oxide, finally add 0.714ml NaF, ultrasonic 60min, ultrasonic power is 300W; The mixed solution of NaF-silicon / graphene oxide composite material can be obtained.

[0043] 3) Add the mixed solution obtained in step (2) into an aqueous solution (concentration: 5 mg / L) containing 200 mg of sucrose, and conduct a hydrothermal reaction at 180° C. for 24 hours.

[0044] 4) The sample prepared in step (3) was raised to 1000° C. at a heating rate of 3 minutes under an argon atmosphere, and the temperature was kept at a constant temperature for 2 hours; 25 ml of the composite material with a mass fraction of 10% hydrofluoric acid was soaked and carbonized, an...

Embodiment 3

[0047] 1) LiF (0.2molL -1 ) configuration: Take 30mL of LiF solution and dilute it to 70ml to obtain the solution with the required concentration.

[0048] 2) Mixed solution of LiF-silicon / graphene oxide composite material: Weigh 220 mg of silicon nanoparticles and add them to a mixed solvent of absolute ethanol / water = 1:1. Aqueous sol (3mg / L) containing 88mg graphene oxide, finally add 2.6ml LiF, ultrasonic 30min, ultrasonic power is 600W; A mixed solution of LiF-silicon / graphene oxide composite material can be obtained.

[0049] 3) Add the mixed solution obtained in step (1) into 1840 mg polyvinyl alcohol aqueous solution (concentration: 3 mg / L), place in a water bath and stir at room temperature for 24 hours;

[0050] 4) Raise the sample prepared in step (2) to 850°C with a heating rate of 3 minutes under an argon atmosphere, and keep the temperature at a constant temperature for 2 hours; measure 133ml of the composite material with a mass fraction of 30% hydrofluoric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com