Fluorine-containing elastomer composition, its production method, molded article, cross-linked article, and covered electric wire

A technology for covering electric wires and manufacturing methods, applied to conductors, circuits, insulators, etc., can solve the problems of reduced flexibility and elongation, and achieve excellent moldability and heat discoloration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0222] [Examples 1 to 6, and Comparative Examples 1 to 9]

[0223] Using an internal mixer, each of the above-mentioned materials was sufficiently kneaded (melt-kneaded) according to the compounding parts (mass basis) shown in Tables 1 to 4, respectively, to obtain the fluoroelastomer composition of each example.

[0224] The temperature of the kneading is set so that the kneading state is good. Specifically, the temperature and time of kneading were set to 240°C×10 minutes in Examples 1 to 6, and 270°C×10 minutes in Comparative Examples 1 to 16, and the rotor speed was set in all examples. It is 150rpm.

[0225] Next, the obtained fluoroelastomer composition was press-molded under the conditions of 250° C.×15 minutes and 10 MPa to produce a sheet having a thickness of about 1 mm. Then, each sheet was subjected to electron beam crosslinking at an irradiation dose of 120 kGy to prepare crosslinked samples of each example.

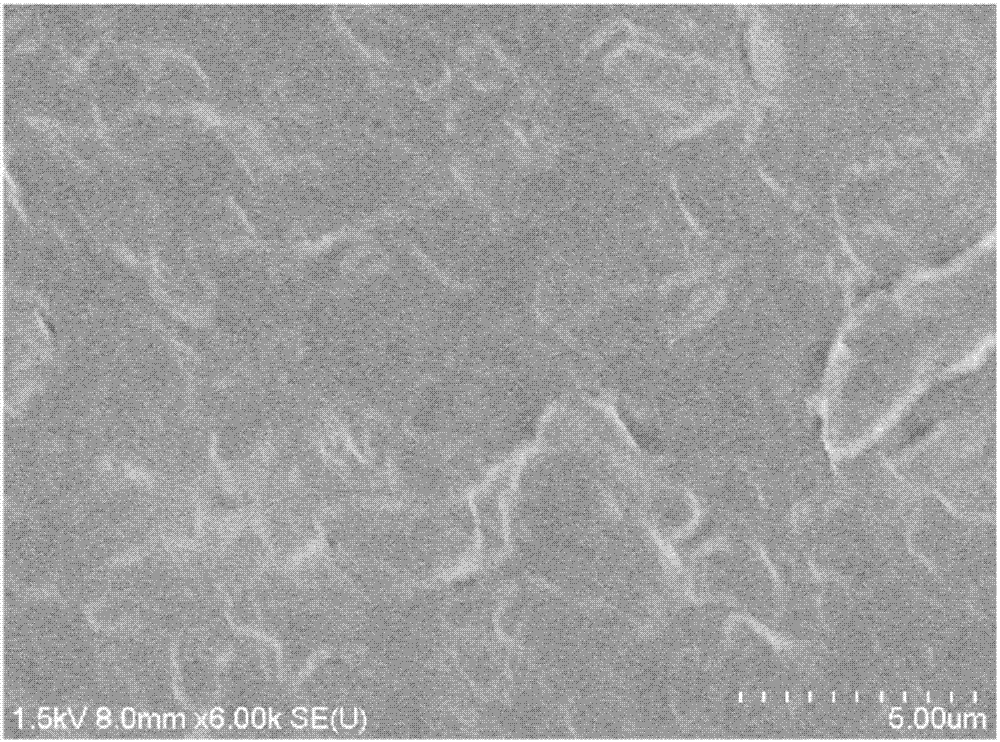

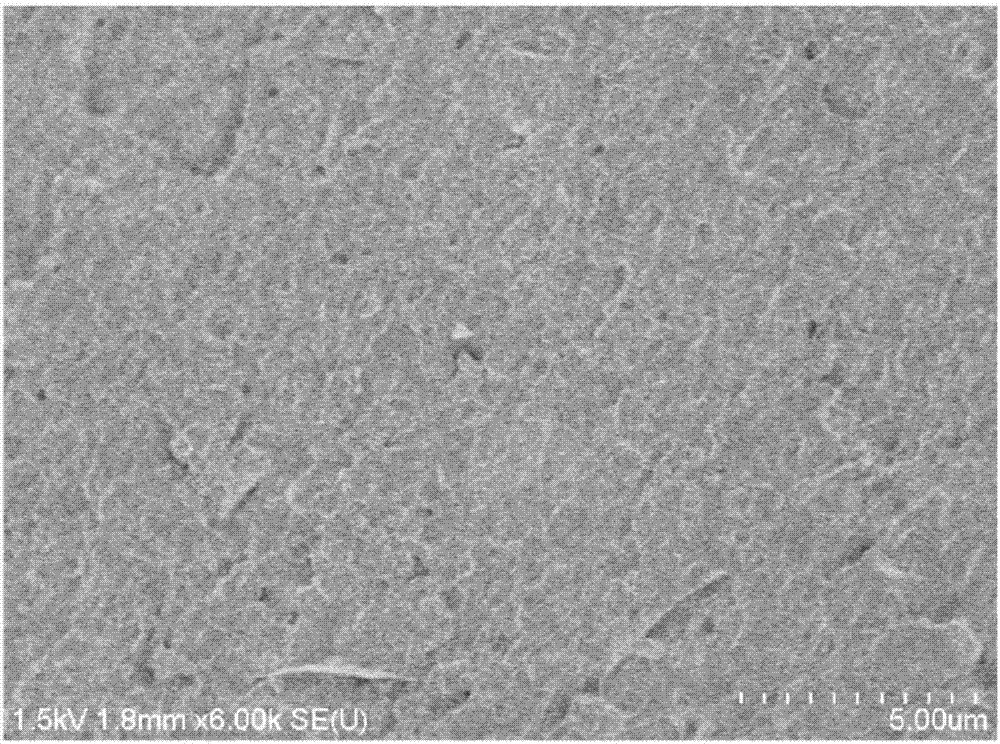

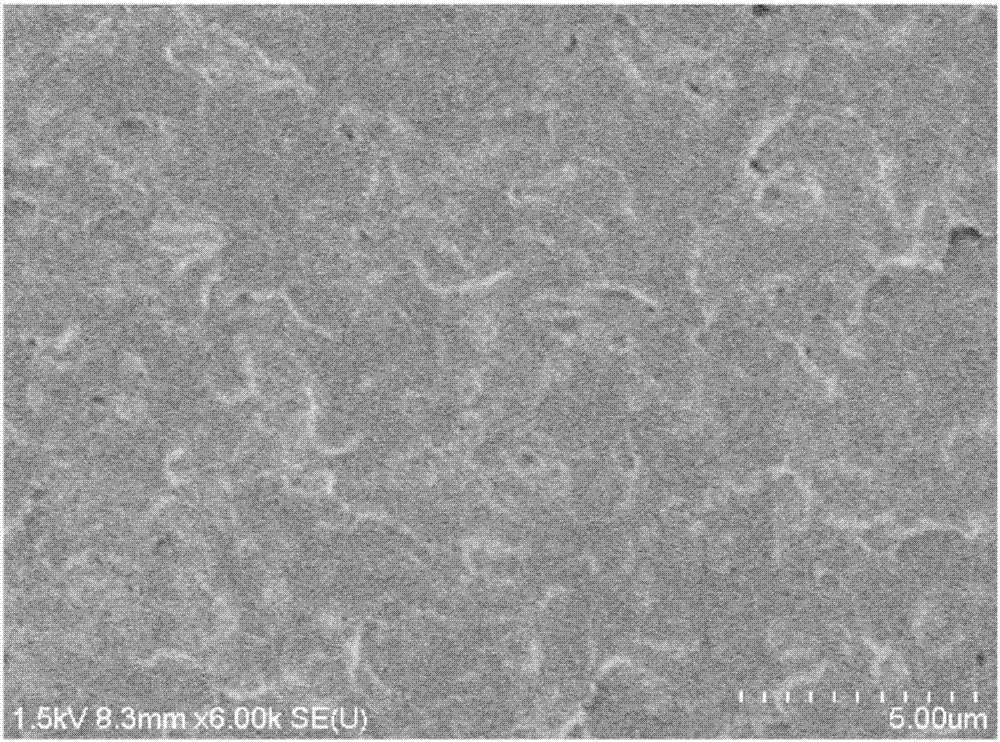

[0226] [Observation of fluoroelastomer composition]

[0227] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com