Hydrodemetallization catalyst with high activity and preparation method thereof

A hydrodemetallization and active metal technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of unsatisfactory mechanical strength of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

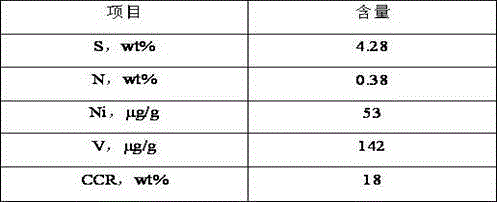

[0034] Weigh the pore volume as 0.9ml / g and the specific surface area as 220m 2 100 grams of gamma-phase cylindrical strip-shaped alumina carrier / g is put into the spray rolling pot, and in the rotating state, spray and impregnate 25 ml of xylitol aqueous solution with a mass concentration of 40% to the carrier in the rolling pot in the form of atomization ; Then continue to spray and impregnate the alumina carrier with 40ml of xylitol aqueous solution with a mass concentration of 20%; finally continue to spray and impregnate the alumina carrier with 40ml of xylitol aqueous solution with a mass concentration of 10%. After impregnation, transfer the alumina carrier into the autoclave and place the autoclave in an oven at 80°C for heat treatment for 120 minutes, then raise the temperature to 180°C, carbonize for 9 hours under autogenous pressure, and cool down to room temperature naturally. The alumina carrier after hydrothermal treatment was dried at 120° C. for 3 hours. After...

Embodiment 2

[0036] With embodiment 1, just use the aqueous solution of 30% sorbitol with 30ml mass concentration when spraying and impregnating for the first time, be the aqueous solution of 10% sorbitol with 50ml mass concentration when spraying and impregnating for the second time, spray for the third time When soaking, use 20ml of sorbitol aqueous solution with a mass concentration of 5%, the heat treatment temperature is 130°C, and the heat treatment time is 60 minutes. During the carbonization treatment, the temperature was 200° C., and the carbonization time was 8 hours. Active component impregnation process with 150ml containing MoO 3 10.5 grams (molybdenum source comes from ammonium molybdate), NiO2 grams (nickel source comes from nickel nitrate) impregnation solution. The hydrodemetallization catalyst C2 of the present invention was prepared, and the properties of the catalyst are shown in Table 1.

Embodiment 3

[0038] With embodiment 1, just adopt four times of spray impregnation, use 20ml mass concentration to be the aqueous solution of mannitol of 50% during the first spray impregnation, use 40ml mass concentration to be 30% sorbitol during the second spray impregnation 20ml aqueous solution of sorbitol with a mass concentration of 20% for the third spray dipping, and 20ml aqueous solution of sorbitol with a mass concentration of 10% for the fourth spray dipping, heat treatment temperature is 100°C, heat treatment The time is 90 minutes. During the carbonization treatment, the temperature was 240° C., and the carbonization time was 12 hours. Active component impregnation process with 150ml containing MoO 3 11.5 grams (molybdenum source comes from ammonium molybdate), NiO2.5 grams (nickel source comes from basic nickel carbonate) impregnating solution. The hydrodemetallization catalyst C3 of the present invention was prepared, and the properties of the catalyst are shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com