Preparation method of paraffin hydrocarbon shape-selective isomerization catalyst

A catalyst and isomerization technology, which is applied in the field of preparation of paraffin-selective isomerization catalysts, can solve the problems of unsatisfactory position of hydrogenation active components, unreasonable pore structure of catalyst, unsatisfactory catalyst activity and selectivity, etc. , to improve the activity and selectivity, ensure the addition/dehydrogenation rate, and improve the diffusion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

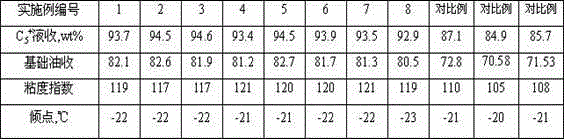

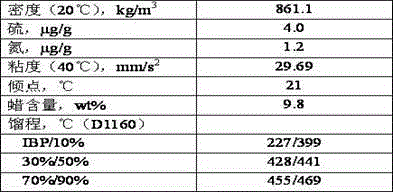

Embodiment 1

[0026] (1) Dissolve chloroplatinic acid containing 0.3 grams of platinum in 6 grams of water, fully mix 10 grams of 200-mesh cellulose with the above solution, and dry the mixture at 80°C for 6 hours to obtain platinum-loaded cellulose;

[0027] (2) 45 grams of ZSM-23 molecular sieve (particle size 0.5 microns, SiO 2 / Al 2 o 3 The molar ratio is 35), 72 grams of aluminum hydroxide (i.e. SB produced by Germany Condean company, dry basis 76%), the platinum-loaded cellulose prepared in step (1), 50 ml of 0.2 M nitric acid solution and 30 ml of water Kneading to make it into a paste-like plastic, forming a cylindrical strip with a diameter of 1.5mm on an extruder, drying the cylindrical strip at 110°C for 8 hours, and then calcining at 650°C for 4 hours in an air atmosphere to obtain a catalyst. The catalyst is composed of Pt: 0.3%, ZSM-32: 45%, pore-forming agent: 10%, alumina: the balance. The pore volume of the catalyst with a pore diameter of 1-10nm accounts for 7.4% of the...

Embodiment 2

[0030] Same as Example 1, the difference is that the substance content is adjusted in each step, SSZ-32 molecular sieve (particle size is 0.7 micron, SiO 2 / Al 2 o 3 The molar ratio is 25) to replace the ZSM-23 molecular sieve, and the catalyst composition is obtained as Pt: 0.02%, SSZ-32: 30%, pore-forming agent: 10%, and alumina: the balance. See Table 2 for the evaluation results.

Embodiment 3

[0032] Same as Example 1, the difference is that the substance content in each step is adjusted, silica gel replaces aluminum hydroxide, and the catalyst composition is obtained as Pt: 0.02%, ZSM-23: 35%, pore-forming agent: 10%, silicon oxide: margin. See Table 2 for the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com