High-performance fiberglass winding yarn sizing agent and preparation method thereof

A technology for glass fiber and sizing agent, applied in the field of glass fiber sizing agent, can solve the problems of unfavorable composite material processing mechanical properties, inability to meet processing performance, poor storage stability, etc., and achieve simplified configuration and preparation process, good processing performance, compatibility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

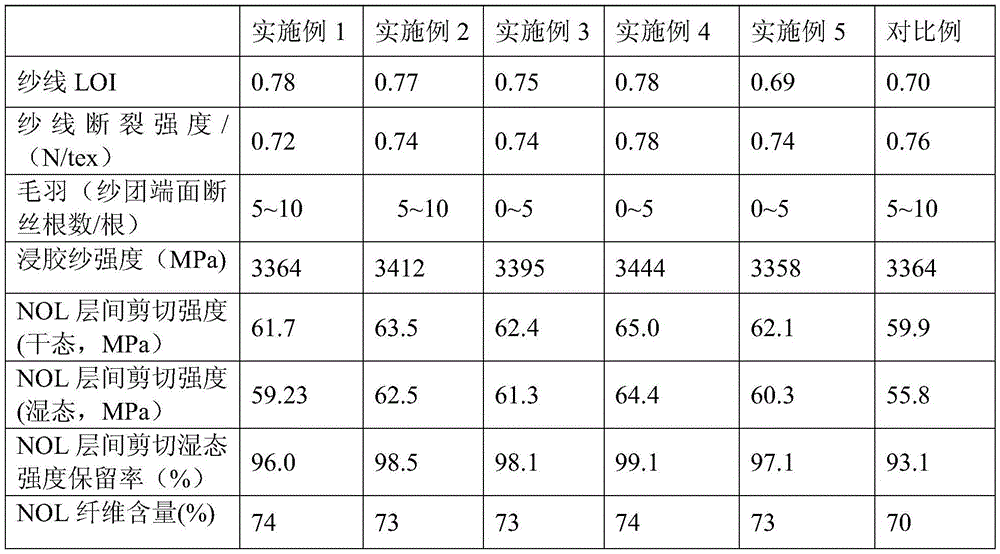

[0025] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0026] The formula of embodiment 1-5 sees the following table:

[0027] sizing component

Example 1

Example 2

Example 3

Example 4

Example 5

epoxy resin emulsion

66.29

66.29

62.29

61.15

63.84

A-1100

-

10.19

0.7

8.34

8.53

A-187

10.19

-

9.49

-

-

A-174

-

-

-

3.33

-

PEG-400 monooleate

19.27

19.27

23.27

22.84

23.85

1.19

1.19

1.19

1.17

1.22

Glacial acetic acid

3.06

3.06

3.06

3.17

2.56

Total solid content of sizing agent

100

100

100

100

100

[0028] Note: Epoxy resin em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com