1,3-propanediol synthesis method

A synthesis method and technology of propylene glycol, which are applied in chemical instruments and methods, preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low yield and selectivity of propylene glycol, and improve the activity. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

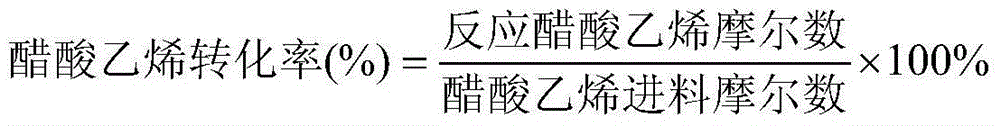

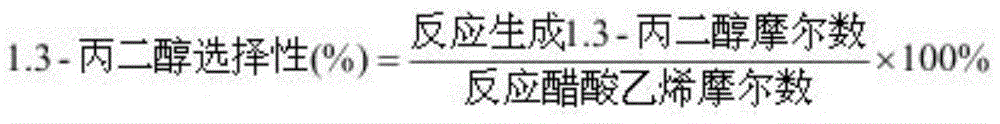

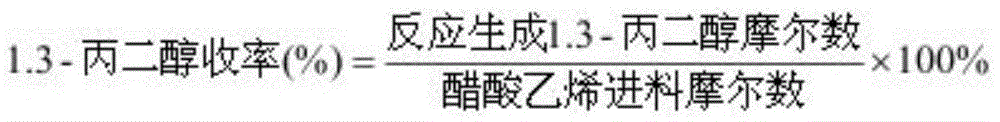

Image

Examples

Embodiment 1

[0027] The preparation of hydroformylation catalyst: the RhCl that contains 6.50gRh, contains 1.50gLi and contains 3.50gSn 3 ·3H 2 O, LiCl, and SnCl 2 2H 2 O is fully mixed and dissolved in an aqueous hydrochloric acid solution with a concentration of 8wt%, to obtain 400ml of impregnation solution, and the specific surface of 1.0L is 168m 2 / g, spherical SiO with a pore volume of 0.94 and a diameter of 5.6mm 2 The carrier was immersed in the above impregnating solution, left to stand for 3 hours and dried at 100° C. to obtain the catalyst. The Rh content of the catalyst was measured by ICP to be 6.50 g / L, the Li content was 1.50 g / L, and the Sn content was 3.50 g / L.

[0028] Synthesis of 1,3-propanediol:

[0029] Step (1): Add 2.50 mol of toluene, 0.02 mol of hydroformylation main catalyst, 0.20 mol of triphenylphosphine and 1.65 mol of vinyl acetate into a 1L titanium reactor. 1.0MPa, then feed carbon monoxide and hydrogen until the pressure is 5.2MPa, increase the stir...

Embodiment 2

[0035] The preparation of hydroformylation catalyst: the RhCl that contains 6.50gRh, contains 1.50gLi and contains 3.50gTi 3 ·3H 2 O, LiCl, and TiCl 4 Fully mix and dissolve in an aqueous hydrochloric acid solution with a concentration of 8wt%, to obtain 400ml of impregnation solution, and the specific surface of 1.0L is 168m 2 / g, spherical SiO with a pore volume of 0.94 and a diameter of 5.6mm 2 The carrier was immersed in the above impregnating solution, left to stand for 3 hours and dried at 100° C. to obtain the catalyst. The Rh content of the catalyst measured by ICP is 6.50 g / L, Li content 1.50g / L, Ti content 3.50g / L.

[0036] Synthesis of 1,3-propanediol:

[0037] Step (1): Add 2.50 mol of toluene, 0.02 mol of hydroformylation main catalyst, 0.20 mol of triphenylphosphine and 1.65 mol of vinyl acetate into a 1L titanium reactor. 1.0MPa, then feed carbon monoxide and hydrogen until the pressure is 5.2MPa, increase the stirring speed to 800rpm, stir and heat up to...

Embodiment 3

[0053] The preparation of hydroformylation catalyst: the Rh(OAc) that contains 6.50gRh, contains 1.50gK and contains 3.50gGe 3 、K 2 SO 4 and GeCl 4 Fully mixed and dissolved in 10wt% acetic acid aqueous solution to obtain 400ml of impregnating solution, and the specific surface of 1.0L was 200m 2 / g, spherical Al with a pore volume of 1.00 and a diameter of 5.6mm 2 o 3 The carrier was immersed in the above impregnating solution, left to stand for 3 hours and dried at 100° C. to obtain the catalyst. The Rh content of the catalyst was determined by ICP to be 6.50 g / L, the K content to be 1.50 g / L, and the Ge content to be 3.50 g / L.

[0054] Synthesis of 1,3-propanediol:

[0055] Step (1): Add 2.50 mol of toluene, 0.02 mol of hydroformylation main catalyst, 0.20 mol of triphenylphosphine and 1.65 mol of vinyl acetate into a 1L titanium reactor. 1.0MPa, then feed carbon monoxide and hydrogen until the pressure is 5.2MPa, increase the stirring speed to 800rpm, stir and heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com