Preparation method for hindered bisphenol type antioxidant

A technology of antioxidant and phenolic type, which is applied in the field of preparation of lubricating oil antioxidant, can solve the problems of increasing solvent recovery cost and consuming large solvent, and achieve better product color, simple production process and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Add 422g (2.05mol) of 2,6-di-tert-butylphenol and 10mL of mixed acid solution (5mL of acetic acid and 5mL of phosphoric acid) into a 1L reactor equipped with mechanical stirring, a thermometer and a reflux condenser, and heat in a water bath at 60°C , when 2,6-di-tert-butylphenol was fully melted, 99.48mL formaldehyde solution (37wt%) (1mol) was added dropwise, after the dropwise addition was completed, stirred in a constant temperature water bath at 70°C for 3 hours. Wash with deionized water at 50°C for 4 times, using 400 mL of deionized water each time, until the washing liquid is neutral, vacuum-dry for 24 hours after suction filtration under reduced pressure. Recrystallize with 800mL of toluene and isooctane mixed solvent, each of toluene and isooctane is 400mL, after suction filtration and vacuum drying, 360g of yellow needle-like crystals are obtained. The yield is 85% and the purity is 99.7%.

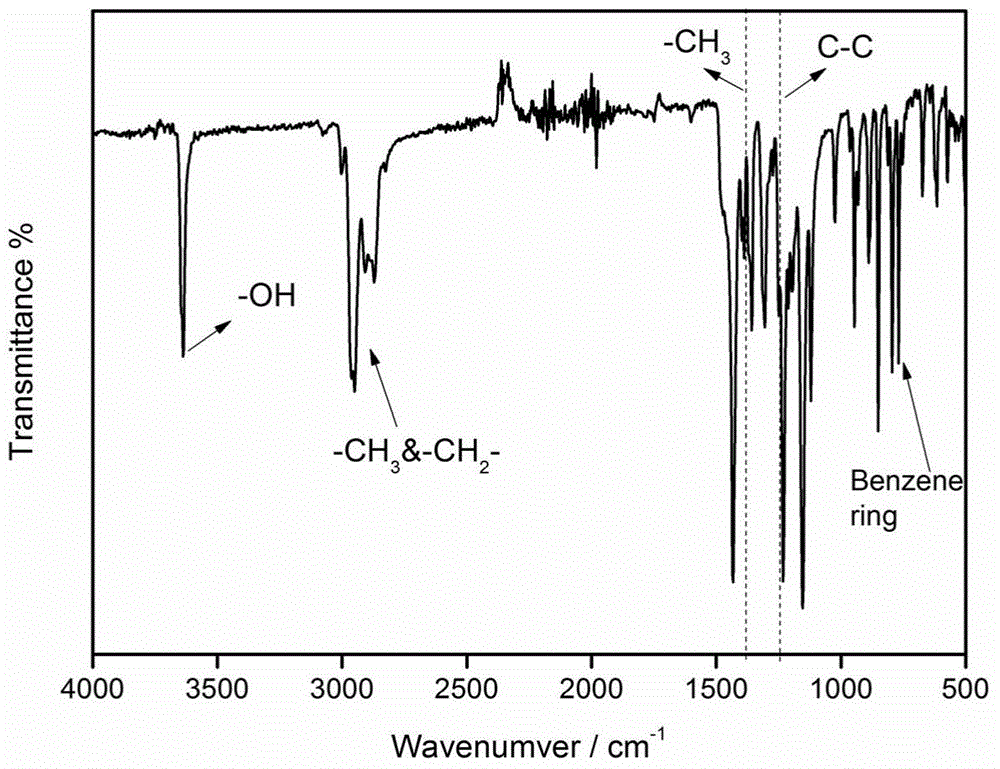

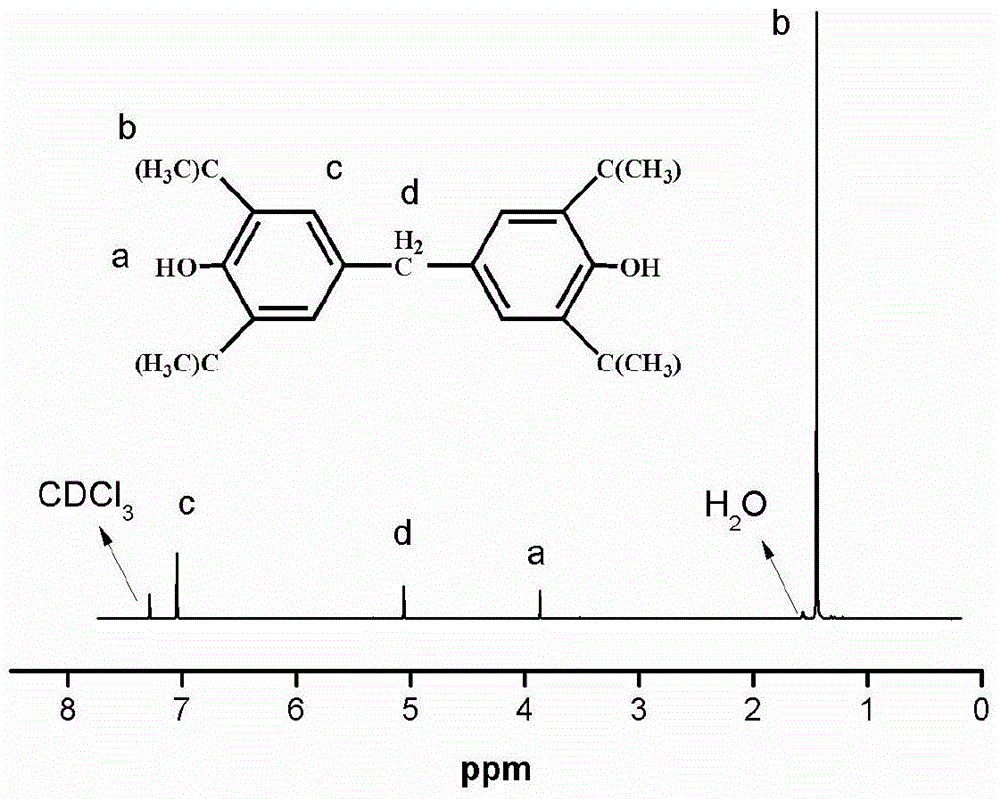

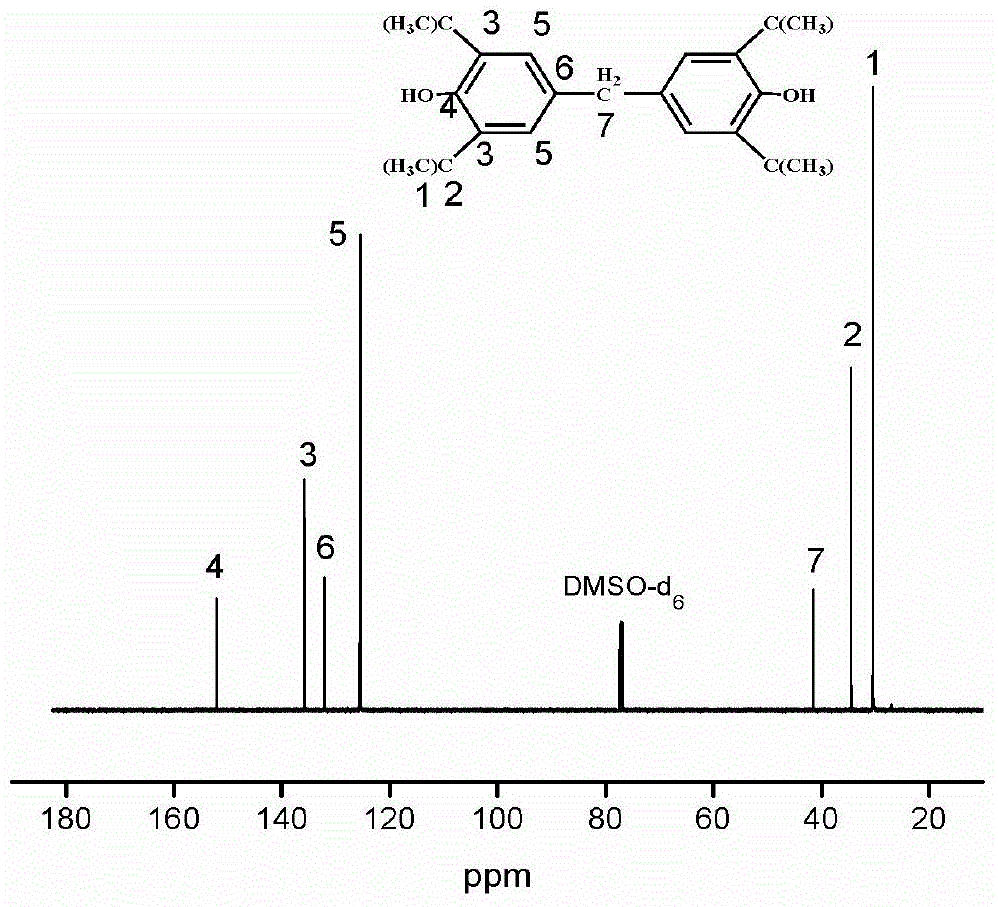

[0062] And characterize the obtained product, the characterization r...

Embodiment 2

[0068] Add 226.6g (1.1mol) of 2,6-di-tert-butylphenol and 8.8mL of mixed acid solution (4.4mL of acetic acid and 4.4mL of formic acid) into a 500mL three-necked flask equipped with mechanical stirring, a thermometer and a reflux condenser. Stir in a water bath at 40°C. After 2,6-di-tert-butylphenol is fully melted, add 46mL of formaldehyde solution (40wt%) (0.5mol) dropwise. After the addition is complete, stir in a constant temperature water bath at 80°C for 4 hours. Wash with deionized water at 40°C for 5 times, using 200 mL of deionized water each time, until the washing solution is neutral, vacuum-dry for 24 hours after suction filtration under reduced pressure. Recrystallize with 300mL toluene and isooctane mixed solvent, 150mL each of toluene and isooctane, filter with suction, and vacuum dry to obtain 191g of yellow needle-like crystals, the yield is 90% and the purity is 99.6%.

Embodiment 3

[0070] Add 422g (2.05mol) of 2,6-di-tert-butylphenol, 6.15mL of mixed acid solution (3.075mL of carbonic acid and 3.075mL of formic acid) into a 1L reactor equipped with mechanical stirring, a thermometer and a reflux condenser, at 50°C Stir in a water bath. After the 2,6-di-tert-butylphenol is fully melted, add 97.11 mL of formaldehyde solution (37 wt%) (0.976 mol) dropwise. After the dropwise addition, stir in a constant temperature water bath at 60°C for 3 hours. Wash with deionized water at 45°C for 3 times, each time using 400 mL of deionized water, and vacuum-dry the filter cake for 24 hours after suction filtration under reduced pressure. Recrystallize with a mixed solvent of 600 mL of toluene and isooctane, 300 mL of toluene and 300 mL of isooctane, filter with suction, and dry in vacuum to obtain 368 g of yellow needle-like crystals. The detected yield was 87%, and the purity was 99.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com