A kind of preparation method of ethoxymethoxymethane

A technology of ethoxymethoxymethane and dimethoxymethane, which is applied in the field of preparation of ethoxymethoxymethane, can solve the problems of low EMM yield, achieve high selectivity, simple products, and no pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

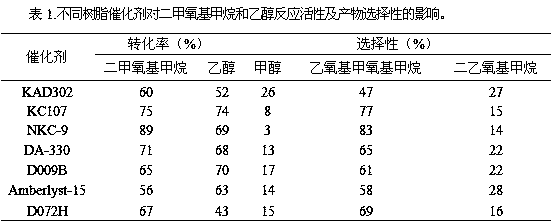

[0024] Add 38 g of dimethoxymethane, 23 g of ethanol and 3 g of catalysts into a 180 mL autoclave. The catalysts are KAD302 (Beijing Kairui Environmental Protection), KC107 (Tianjin Yunkai), NKC-9 (Tianjin Bohong) , DA-330 (Jiangsu Tehua), D009B (Dandong Pearl), Amberlyst-15 (Jiangsu Sekesaisi), D072H (Tianjin Yunkai). use N 2 Under the condition of 1.0 MPa, replace the air in the kettle three times, so that the remaining air content in the kettle is less than 0.1%, and then pass 2.0 MPa N 2 , let it stand for 30 minutes, and use it for leak testing of the reactor to ensure that the device is airtight and then evacuate the gas in the reactor. Under the condition of ensuring airtightness, the reaction was heated and heated. The stirring speed of the reactor was 500 rpm, the reaction pressure was 0.1 MPa, the reaction temperature was 70°C, and the reaction time was 4 hours. The reaction results are shown in Table 1.

[0025]

[0026] From the reaction data in Table 1, it ca...

Embodiment 2

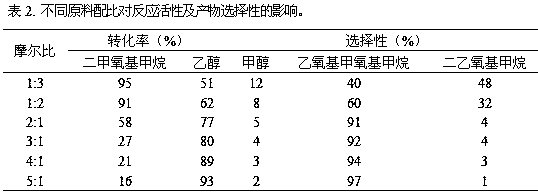

[0028] Under the condition of normal pressure and 70 ℃, add the raw materials dimethoxymethane and Ethanol and 3 g of NKC-9 catalyst (the quality of ethanol is 23 g), at room temperature with N 2 Under the condition of 1.0 MPa, replace the air in the kettle three times, so that the remaining air content in the kettle is less than 0.1%, and then pass 2.0 MPa N 2 , let it stand for 30 minutes, and use it for leak testing of the reactor to ensure that the device is airtight and then evacuate the gas in the reactor. Under the condition of ensuring no air leakage, heating was carried out under normal pressure, the stirring speed of the reactor was 500 rpm, and the reaction time was 4 hours. The influence of different raw material ratios on the reaction activity and product selectivity is shown in Table 2.

[0029]

[0030] It can be seen from Table 2 that at normal pressure and 70°C, after 4 hours of reaction, different molar ratios of the reaction raw materials dimethoxymethan...

Embodiment 3

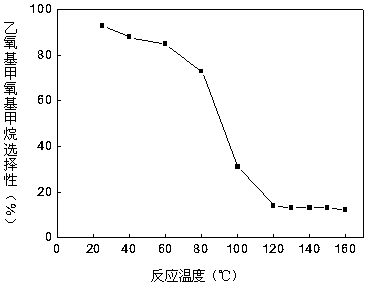

[0032] Add 38 g of dimethoxymethane, 23 g of ethanol, and 3 g of NKC-9 catalyst in a 180 mL autoclave, and use N 2 Replace the air in the kettle three times under the condition of 1.0 MPa, so that the remaining air content in the kettle is less than 0.1%, and then pass 2.0 MPa N 2 , let it stand for 30 minutes, and use it for leak testing of the reactor to ensure that the device is airtight and then evacuate the gas in the reactor. Under the condition of ensuring no air leakage, heat up the temperature, the stirring speed of the reactor is 500 rpm, the reaction time is 4 hours, the reaction pressure is 0.1 MPa, and the reaction temperatures are 25 ℃, 40 ℃, 60 ℃, 80 ℃, 100 ℃ respectively , 120 °C, 130 °C, 140 °C, 150 °C, 160 °C, the reaction results under different reaction temperature conditions are shown in Table 3.

[0033]

[0034] It can be seen from Table 3 that when NKC-9 is used as a catalyst, the reaction is carried out under normal pressure for 4 hours, and when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com