Azobenzene fluorescence sensor and preparation method and application thereof

A fluorescent sensor and azobenzene-based technology, applied in the field of fluorescent sensors, can solve the problems of poor selectivity of metal ions, etc., and achieve the effects of simple preparation method, obvious detection phenomenon, and easy identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of an azobenzene fluorescent sensor-zinc ion fluorescent sensor comprises the following steps:

[0039] 1) Add 2,2′-dihydroxyazobenzene (1.5mmol), potassium carbonate (3.0mmol) and 18-crown-6 (0.2mmol) to 20ml of anhydrous acetone, stir at room temperature for 10min, pass Hexadecanoyl chloride (1.5mmol) was slowly added dropwise into the constant pressure dropping funnel. After the dropwise addition was completed within 1h, it was heated to reflux for 15h, and the insoluble matter was removed by filtration to obtain a sample after the reaction was completed.

[0040] 2) Separation and purification of the sample after the reaction is completed:

[0041] After the sample after the reaction was completed, the solvent was distilled off at 0.1 Pa with a rotary evaporator to obtain a brownish-red solid;

[0042] Then use the mixed solution of ethyl acetate and petroleum ether, in volume ratio, ethyl acetate: petroleum ether = 1:10, as the eluent, and use...

Embodiment 2

[0044] A preparation method of an azobenzene fluorescent sensor-zinc ion fluorescent sensor comprises the following steps:

[0045] 1) Add 2,2'-dihydroxyazobenzene (1.5mmol), potassium carbonate (4.5mmol) and 18-crown-6 (0.2mmol) to 50ml of anhydrous acetone, stir at room temperature for 10min, pass Hexadecanoyl chloride (2.25mmol) was slowly added dropwise into the constant pressure dropping funnel. After the dropwise addition was completed within 1h, it was heated to reflux for 15h, and the insoluble matter was removed by filtration to obtain a sample after the reaction was completed.

[0046] 2) Separation and purification of the sample after the reaction is completed:

[0047] After the sample after the reaction was completed, the solvent was distilled off at 0.1 Pa with a rotary evaporator to obtain a brownish-red solid;

[0048] Then use the mixed solution of ethyl acetate and petroleum ether, the volume ratio is, ethyl acetate: petroleum ether = 1:5, as eluent, use 200...

Embodiment 3

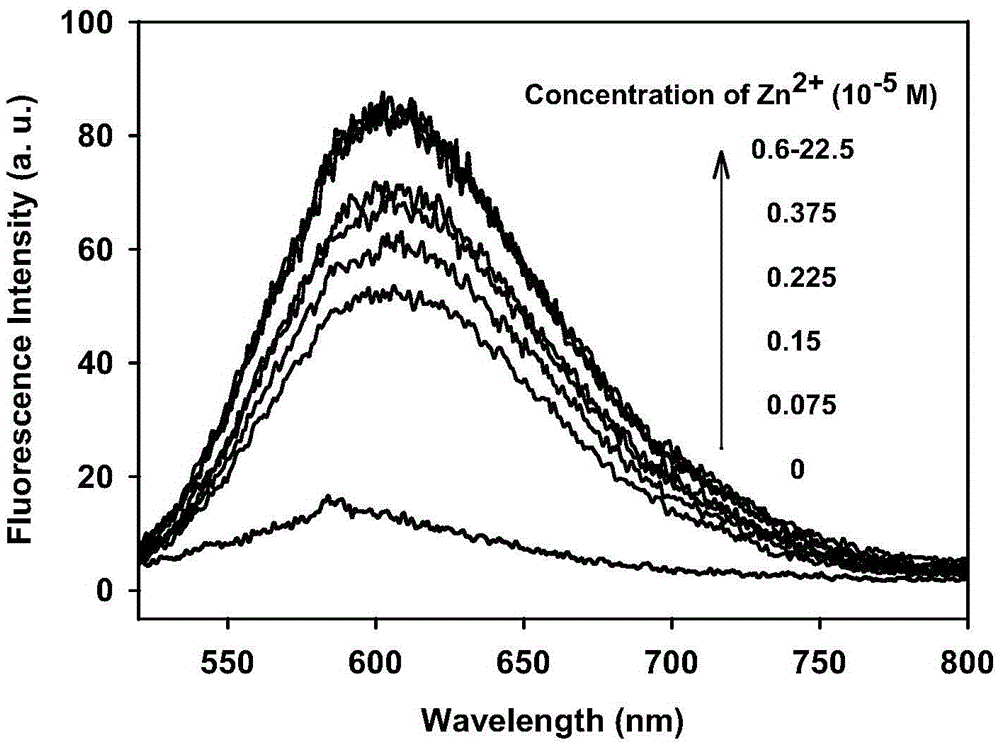

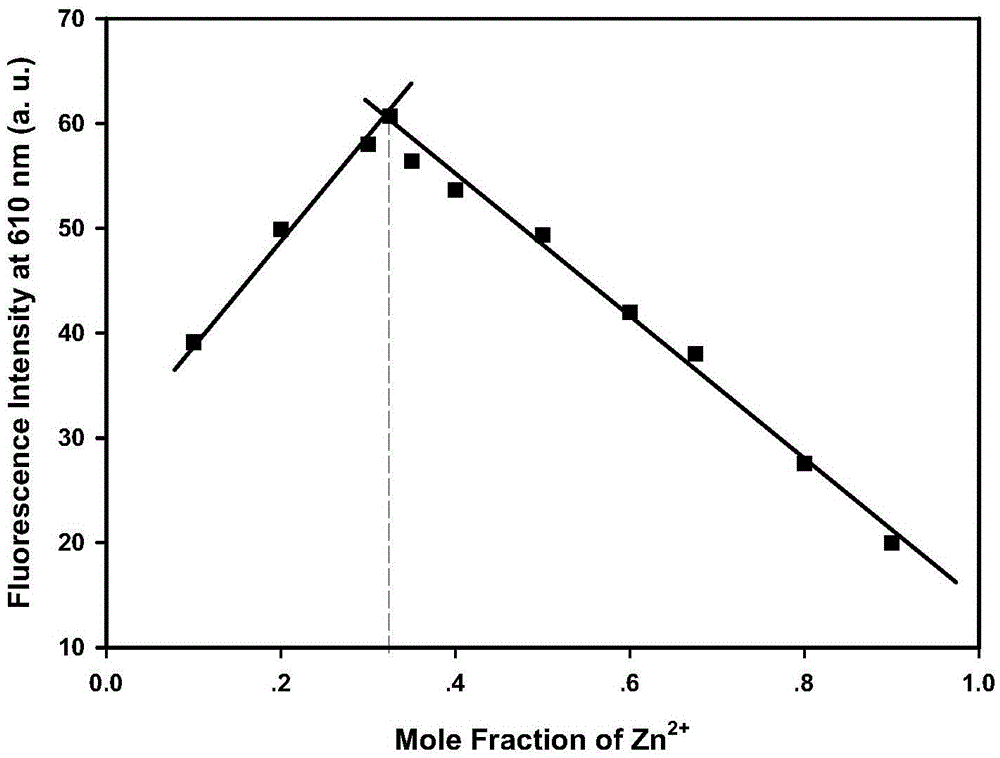

[0050] Titration Test of Fluorescence Sensor and Zinc Ion

[0051] In a mixed solvent (pH=7.5) with a volume ratio of HEPES buffer and methanol of 1:1, a fluorescent sensor with an initial concentration of 0.3 mM was added so that the concentration of the fluorescent sensor in the solution was 15 μM. Then, different amounts of zinc ions with an initial concentration of 0.3 mM were added sequentially, so that the concentrations of zinc ions in the solution were 0.75 μM, 1.5 μM, 2.25 μM, 3.75 μM, 6.0 μM, 7.5 μM, 11.25 μM, 15 μM, 22.5 μM , 37.5 μM, 45 μM, 90 μM, 135 μM, 225 μM, no zinc ions were added as a control, and the system was allowed to stand for 15 minutes to reach equilibrium.

[0052] Fluorescence spectra under different zinc ion conditions were tested with a fluorescence spectrometer, the excitation wavelength was 500nm, and the detection wavelength was 610nm, the results were as follows figure 1 shown. Depend on figure 1It can be seen that as the concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com