Method for using ionic liquid catalyst for catalyzing urea and propylene glycol to synthesize propylene carbonate

A propylene carbonate and ionic liquid technology, applied in the chemical industry, organic chemistry, sustainable manufacturing/processing, etc., can solve the problems of low catalyst catalytic efficiency and difficult catalyst recovery, and achieve high catalytic activity and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

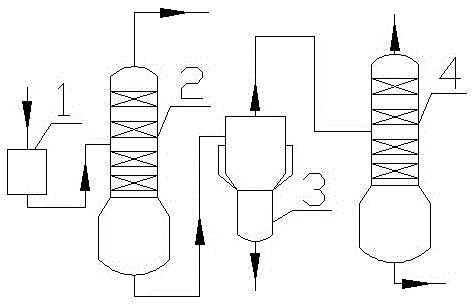

[0014] On a set of 5,000 tons of urea-based propylene carbonate production equipment, the ionic liquid and propylene glycol are first transported into the pre-reaction device (1) for preheating, and after reaching the temperature, the urea is transported to the pre-reaction device (1), and the pre-reaction temperature is The temperature is 50°C-200°C, and the pre-reaction time is 0.1h-6h. After the pre-reaction liquid meets the requirements, the pre-reaction feed liquid is transported from the middle into the propylene carbonate reactive distillation tower (2). During the reactive distillation process, propylene glycol , propylene carbonate and ionic liquid catalyst are heavy components moving from the top of the tower to the bottom of the tower, and the nitrogen generated by the reaction is light components, which are separated from the top of the tower. The reaction rectification temperature is 100-200°C, the urea in the tower kettle is less than 2wt%, and the catalyst conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com