Polyester-type alkaline-water-soluble photocuring resin and preparation method thereof, and photoinduced imaging agent

A light-curing resin and soluble technology, which is applied in the direction of photomechanical equipment, optics, and pattern surface photoplate-making process, etc., can solve the problems of difficult film removal of photoimaging agents, application restrictions, and high viscosity of resins, and meet the requirements of assembly line production Process requirements, excellent alkali water solubility, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

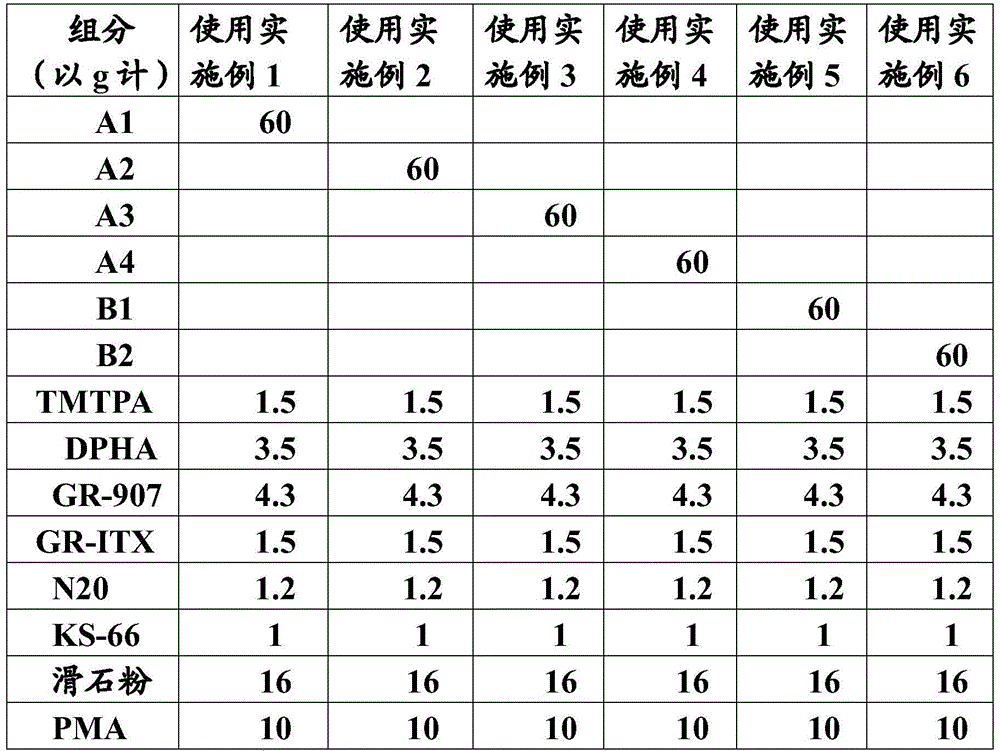

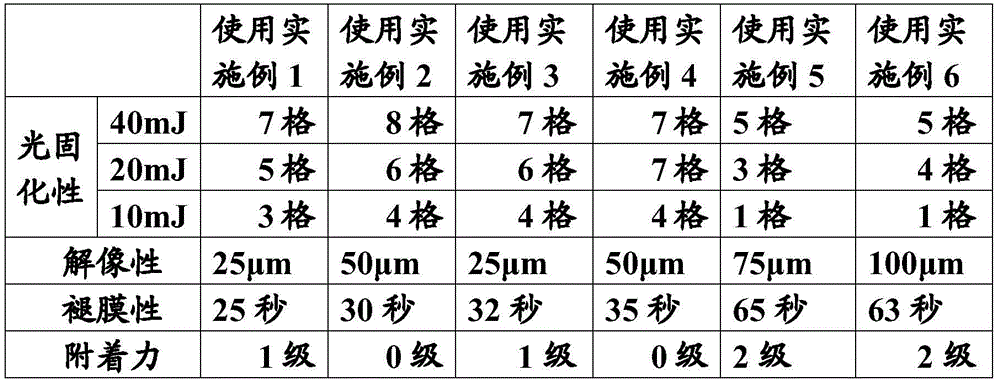

Examples

Embodiment 1

[0045] Add 103g of pyromellitic dianhydride and 210g of diethylene glycol monoethyl ether acetate into a reactor equipped with a thermometer, a stirrer, a reflux condenser and a dropping funnel. The mixture was then heated to 100°C and stirred at constant temperature for 1.5 hours. Then slowly add 59g of 1,6-hexanediol and control the addition within 1 hour. Then react at a constant temperature at 110° C. for 6 hours until the acid value is less than 145 mgKOH / g to obtain a carboxyl group-containing polyester compound.

[0046] Subsequently, the temperature in the reactor was lowered to 90°C, and 109g of propylene glycol methyl ether acetate and 0.1g of polymerization inhibitor hydroquinone were added first, and after constant temperature stirring for 30 minutes, 0.12g of polymerization inhibitor hydroquinone was added. Phenol, 1.7 g catalyst N,N-dimethylbenzylamine and 76.5 g glycidyl methacrylate. After reacting for 16 hours, a polyester-type alkaline water-soluble photocu...

Embodiment 2

[0048] Add 54.53g of pyromellitic dianhydride and 105g of N-methylpyrrolidone into the reactor equipped with thermometer, stirrer, reflux condenser and dropping funnel. The mixture was then heated to 100°C and stirred at constant temperature for 1.5 hours. Then slowly add 54g of hydrogenated bisphenol A and control it dropwise within 1 hour. Then react at a constant temperature at 110° C. for 6 hours until the acid value is less than 135 mgKOH / g to obtain a carboxyl group-containing polyester compound.

[0049] Subsequently, the temperature in the reactor was lowered to 90°C, and 95g of propylene glycol methyl ether acetate and 0.1g of polymerization inhibitor hydroquinone were added first, and after constant temperature stirring for 30 minutes, 0.12g of polymerization inhibitor hydroquinone was added. Phenol, 0.75 g catalyst N,N-dimethylbenzylamine and 25.84 g allyl-2,3-epoxypropyl ether. After reacting for 12 hours, the acid value was 45.8mgKOH / g, the viscosity was 25dPa.s...

Embodiment 3

[0051] Add 54.53g of pyromellitic dianhydride and 105g of N-methylpyrrolidone into the reactor equipped with thermometer, stirrer, reflux condenser and dropping funnel. The mixture was then heated to 100°C and stirred at constant temperature for 1.5 hours. Then slowly add 54g of hydrogenated bisphenol A and control it dropwise within 1 hour. Then react at a constant temperature at a temperature of 110°C for 6 hours until the acid value is less than 135mgKOH / g to obtain a carboxyl-containing polyester compound;

[0052] Subsequently, the temperature in the reactor was lowered to 90°C, and 95g of propylene glycol methyl ether acetate and 0.1g of polymerization inhibitor hydroquinone were added first, and after constant temperature stirring for 30 minutes, 0.12g of polymerization inhibitor hydroquinone was added. Phenol, 0.75 g catalyst N,N-dimethylbenzylamine and 44.3 g 3,4-epoxycyclohexylmethyl methacrylate. After reacting for 12 hours, an acid value of 43.4 mgKOH / g, a viscos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com