Ni nanoparticle modified graphene and preparation method of wave-absorbing material

A nanoparticle and wave-absorbing material technology, applied in the field of functional material preparation, can solve the problem of difficult blending of magnetic nanoparticle-modified graphene, increased agglomeration tendency and stacking tendency between sheets, and the influence of uniform distribution of Ni nanoparticles on the surface, etc. problems, to achieve low reflectivity, low cost of raw materials, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

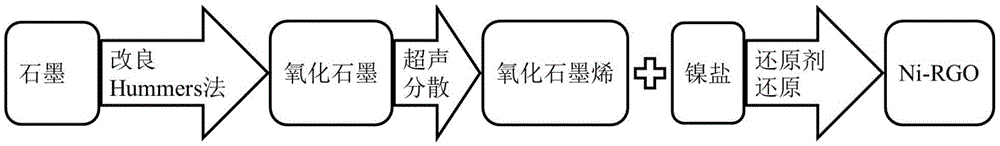

[0037] The present invention proposes a kind of preparation method of Ni nanoparticle modified graphene and wave-absorbing material thereof, prepares Ni nanoparticle modified graphene / epoxy resin wave-absorbing material by one-step method under hydrothermal condition, such as figure 1 As shown, it specifically includes the following steps:

[0038] Step 1: Prepare graphite oxide by Hummers method:

[0039] (1) Take graphite powder, KNO 3 The powder is mixed with concentrated sulfuric acid (the concentration of concentrated sulfuric acid is 75wt% ~ 98.3wt%), and the mixing ratio is to add 1.5 ~ 2g KNO to every 1.5g graphite powder 3 Powder, 65~69ml concentrated sulfuric acid, add KMnO when the obtained mixture is heated to 35~40℃ in water bath 4 Powder, the addition ratio is 8.0~9.5g KMnO per 1.5g graphite 4 , stir magnetically at 100-300r / min, and react for more than 6 hours; then slowly add deionized water to the mixture, and adjust the temperature of the water bath to 60°C-...

Embodiment 1

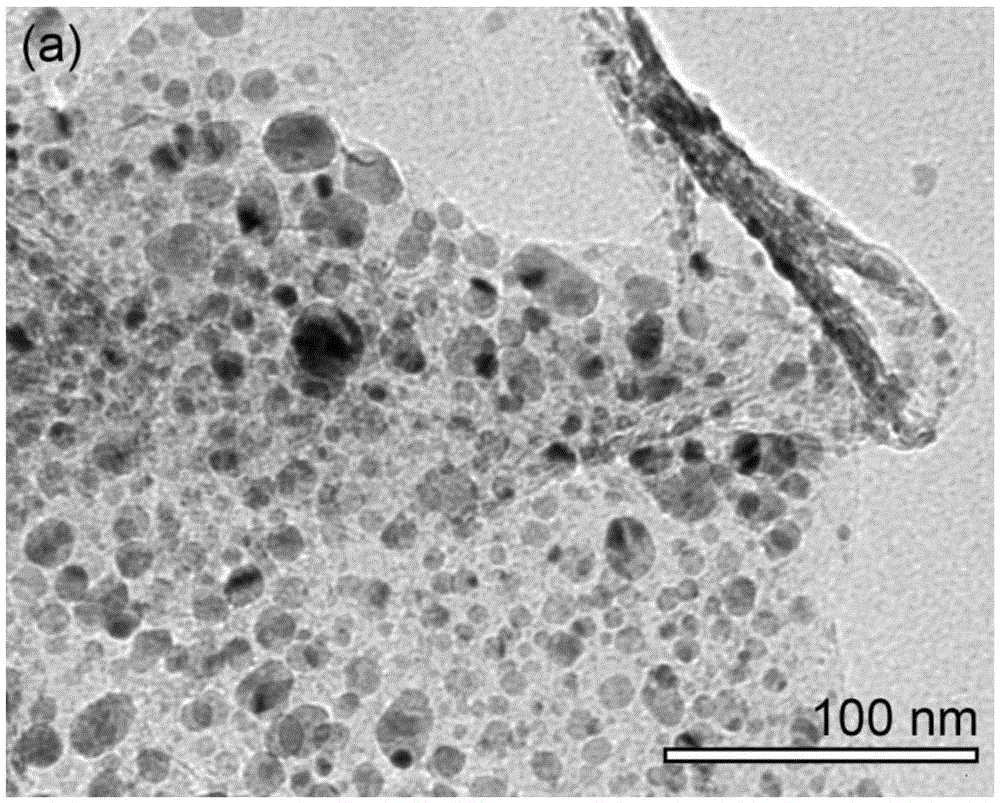

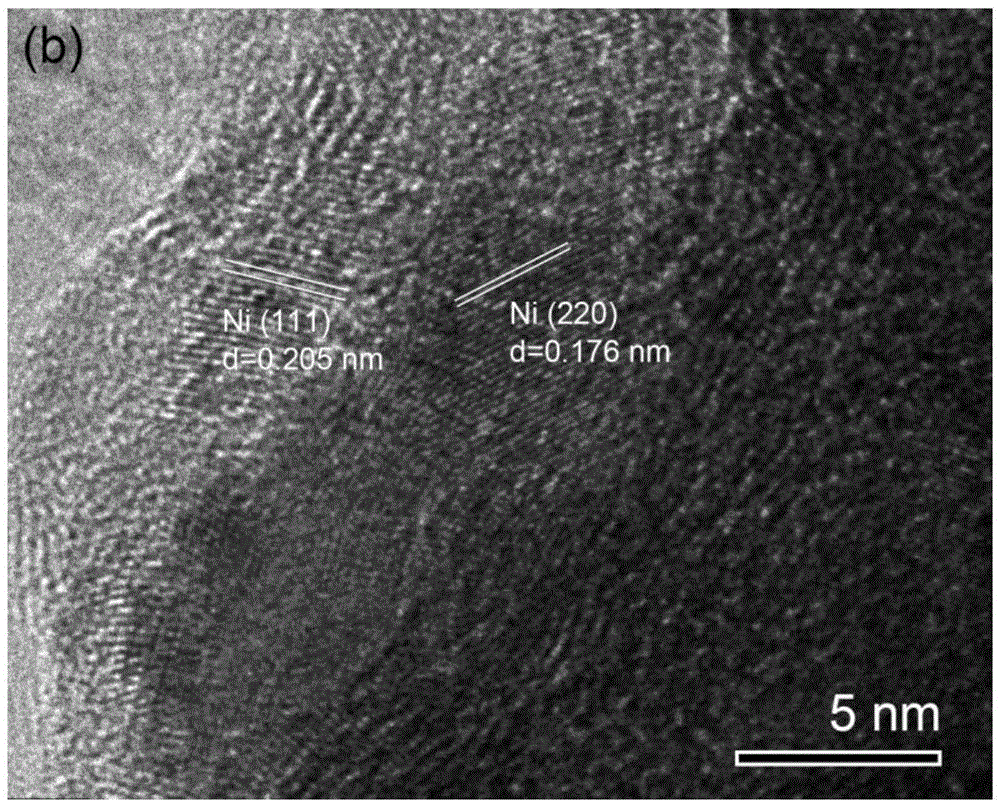

[0064] Graphite oxide was prepared according to step 1, and 100 mg of graphite oxide was dissolved in 100 ml of deionized water, and ultrasonically dispersed for 2 hours to fully peel off the graphite oxide sheets to obtain an aqueous solution of graphene oxide; add 0.5molNi(NO 3 ) 2 ·6H 2 O, ultrasonic dispersion for 1h, after stirring for 1h, dropwise add KOH solution (1M) to the solution, adjust the pH value of the solution to 10, slowly add hydrazine hydrate with a mass percentage concentration of 50%, and reduce graphene oxide and Ni 2+ , react for 2 hours, the solution turns dark brown; stir in a water bath at 60°C for 4 hours, the solution turns from dark brown to black, after the reaction, take out the black solution and wash it in a centrifuge until it is neutral, then vacuum it at 60°C Dry for 10 h, grind into fine powder to obtain Ni-modified graphene (Ni-rGO); dissolve the modified graphene in tetrahydrofuran to obtain a modified graphene suspension, and fix the r...

Embodiment 2

[0068] Prepare graphite oxide according to step 1, take 100mg graphite oxide and dissolve it in 100ml deionized water, ultrasonically disperse for 2 hours to fully peel off the graphite oxide sheet to obtain a graphene oxide aqueous solution; add 1molNiCl to the dispersed graphene oxide aqueous solution 2 ·6H 2 O, ultrasonic dispersion for 1h, after stirring for 1h, dropwise add KOH solution (1M) to the solution, adjust the pH value of the solution to 11, slowly add hydrazine hydrate with a mass percentage concentration of 80%, and reduce graphene oxide and Ni 2+, reacted for 3 hours, the solution turned brown; stirred in a water bath at 70°C for 4 hours, the solution turned from brown to black, after the reaction, the sample was taken out and washed with water in a centrifuge until neutral, then vacuum-dried at 70°C for 8 hours, Grind into fine powder to obtain Ni-modified graphene (Ni-rGO); the modified graphene is dissolved in acetone to obtain a modified graphene suspensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com