Environment-friendly epoxy floor paint and preparation process thereof

An epoxy floor paint, environmental protection technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve problems such as easy to pollute the environment, do not conform to the concept of environmental protection, and affect people's health, and achieve good environmental protection performance, good Corrosion resistance, soft gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

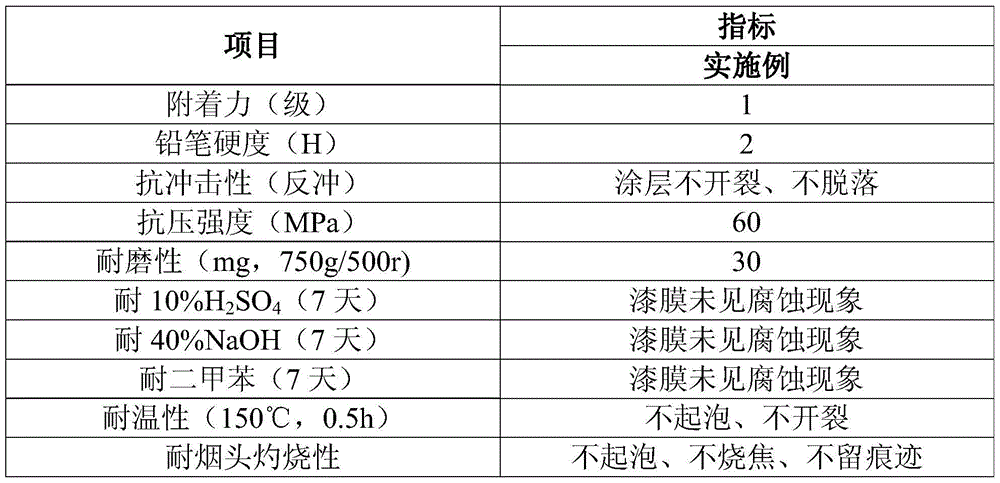

Examples

Embodiment

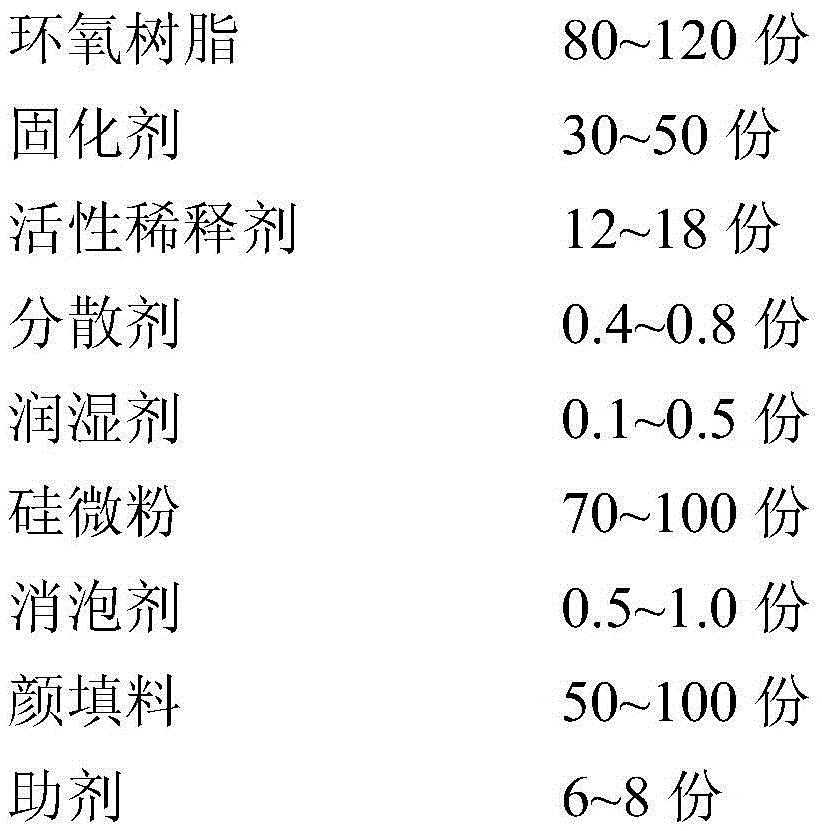

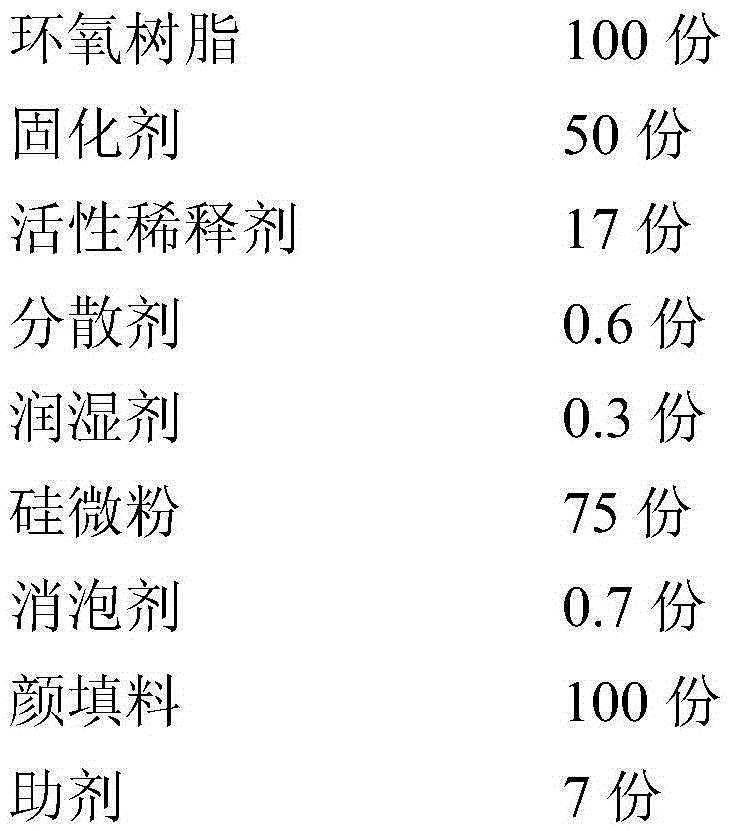

[0018] A kind of environmental protection epoxy floor paint of the present invention, its component and weight ratio are:

[0019]

[0020] The pigments and fillers are food-grade titanium dioxide, red iron oxide, yellow iron oxide, talcum powder, and quartz powder.

[0021] The curing agent is a water-based epoxy curing agent.

[0022] The reactive diluent is epoxy reactive diluent.

[0023] The defoamer is an organosilica modifier.

[0024] The wetting agent is polyoxyethylene alkyl ether.

[0025] A kind of preparation technology of environmental protection epoxy floor paint of the present invention comprises the following steps:

[0026] (1) Prepare the materials according to the above weight ratio;

[0027] (2) After premixing epoxy resin, reactive diluent, curing agent, dispersant, wetting agent, silicon micropowder, defoamer, pigment and filler, and quartz powder, use a high-speed disperser at a speed of 2000 rpm Disperse at high speed for 40 minutes, then grind...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap