Complementary distributed energy system using internal combustion engine exhaust to integrate thermochemical processes

A distributed energy, integrated thermochemical technology, applied in the field of complementary distributed energy systems, can solve the problems of increasing power production, thermal energy loss, and large loss of working power, and achieves the goal of reducing technical risks and reducing share. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

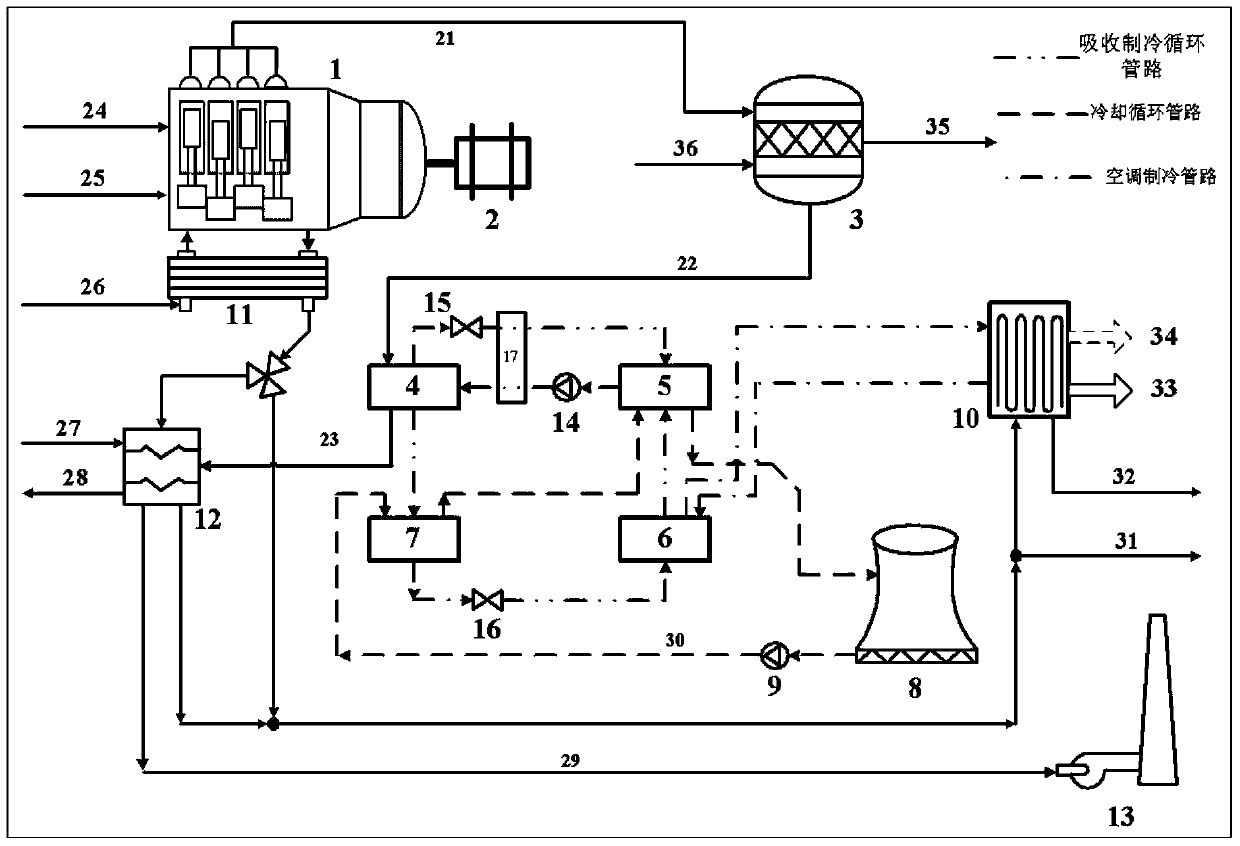

[0036] The complementary distributed energy system that utilizes the exhaust gas of the internal combustion engine to integrate the thermochemical process provided by the present invention uses the waste heat of the high-temperature flue gas discharged from the internal combustion generator set to drive the endothermic chemical reaction process, and utilizes the medium-temperature flue gas discharged from the endothermic chemical reaction process The waste heat drives the absorption refrigeration cycle, and uses the low-temperature flue gas waste heat generated by the absorption refrigeration cycle to generate heating heat, domestic hot water and industrial steam, so as to realize the efficient recovery and utilization of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com