Automated design method and platform oriented to intelligent hardware system development

A technology of intelligent hardware and design method, applied in software design, CAD circuit design, calculation, etc., can solve the problems of poor reusability, narrow application field, long development time, etc., and achieve strong invocability and reusability, The effect of improving market competitiveness, accelerating iteration and convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

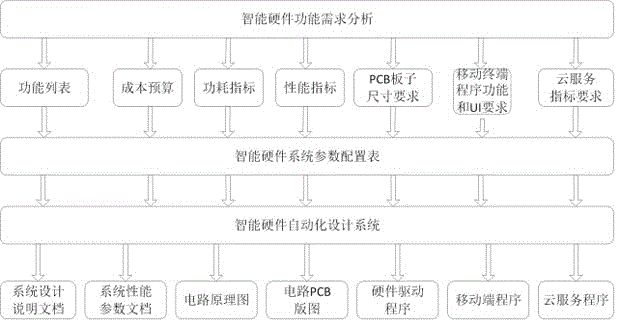

[0033] An automated design method for the development of intelligent hardware systems, such as figure 1 shown, including the following steps:

[0034] Step 1. Create a cloud service program library to store various cloud service program models; create a mobile software database to store software programs based on IOS, Android and WeChat; create a user interface for mobile applications Visual template library, storing various visual user interface templates; creating hardware module library, storing microprocessor, sensor, positioning, mobile communication, short-distance data communication, power management and multimedia hardware modules, creating hardware The underlying driver program and application program library store the hardware driver program and application program corresponding to the hardware module library;

[0035] Step 2. Select the newly developed product and analyze the development requirements of the newly developed product to obtain the function list, cost ...

Embodiment 2

[0043] The difference between this embodiment and the foregoing embodiments is that a third-party resource library can be selected in setting step 3. When selecting a third-party resource library, it is necessary to determine whether the content of the referenced third-party resource library complies with the defined design specification.

[0044] The third-party resource library can provide many additional sub-modules, which increases the options for developers to develop new products and improves the diversity of product development.

Embodiment 3

[0046] The difference between this embodiment and the above embodiment is that step 3 also includes an examination step, as follows:

[0047] Find the relevant parameter information of the newly developed product design requirements from the hardware module library, the underlying hardware driver and application library, the mobile software database, the mobile application user interface visualization template library, and the cloud service library, and judge whether the information is consistent with Whether the defined design specifications or requirements are in compliance, and generate a review report based on the judgment results.

[0048] This review step checks the parameters of the new product and the modules that match the module resource library in order to avoid various parameter mismatch problems in later development.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com