Filling method and device of three-dimensional package vertical through hole

A vertical through-hole, three-dimensional packaging technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of long time, difficult to fill micro-holes, complex process, etc., to achieve low porosity, uniform composition, size high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

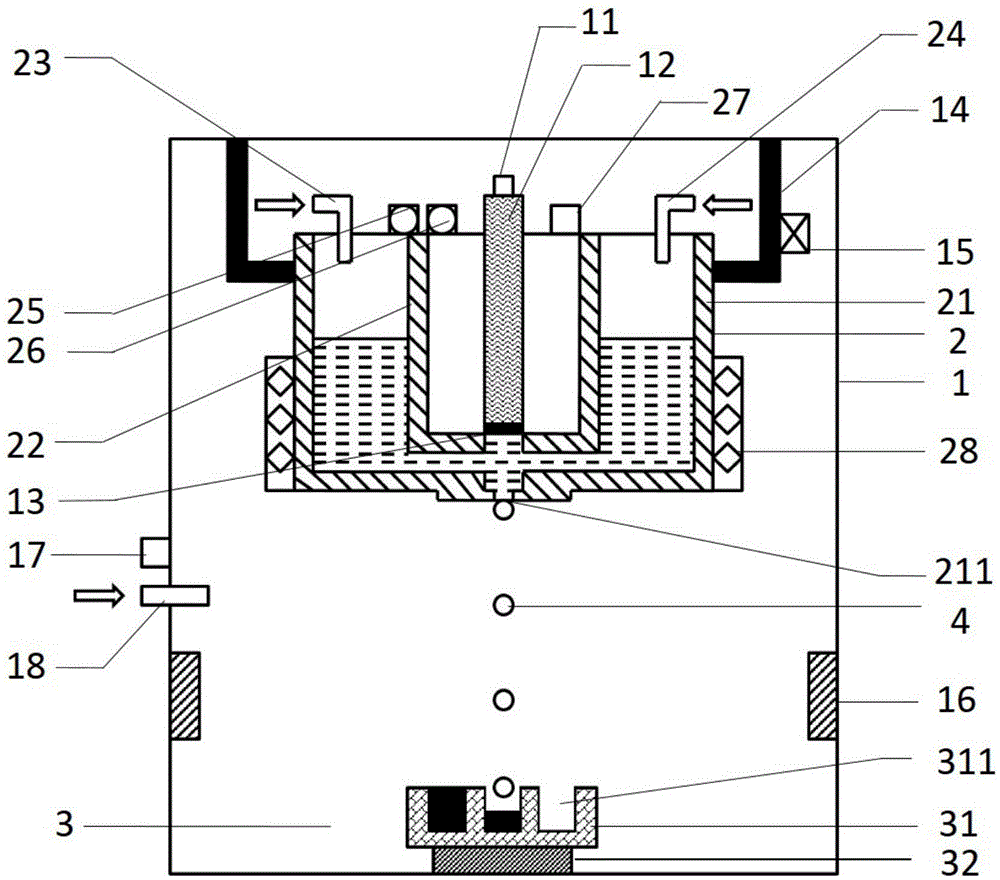

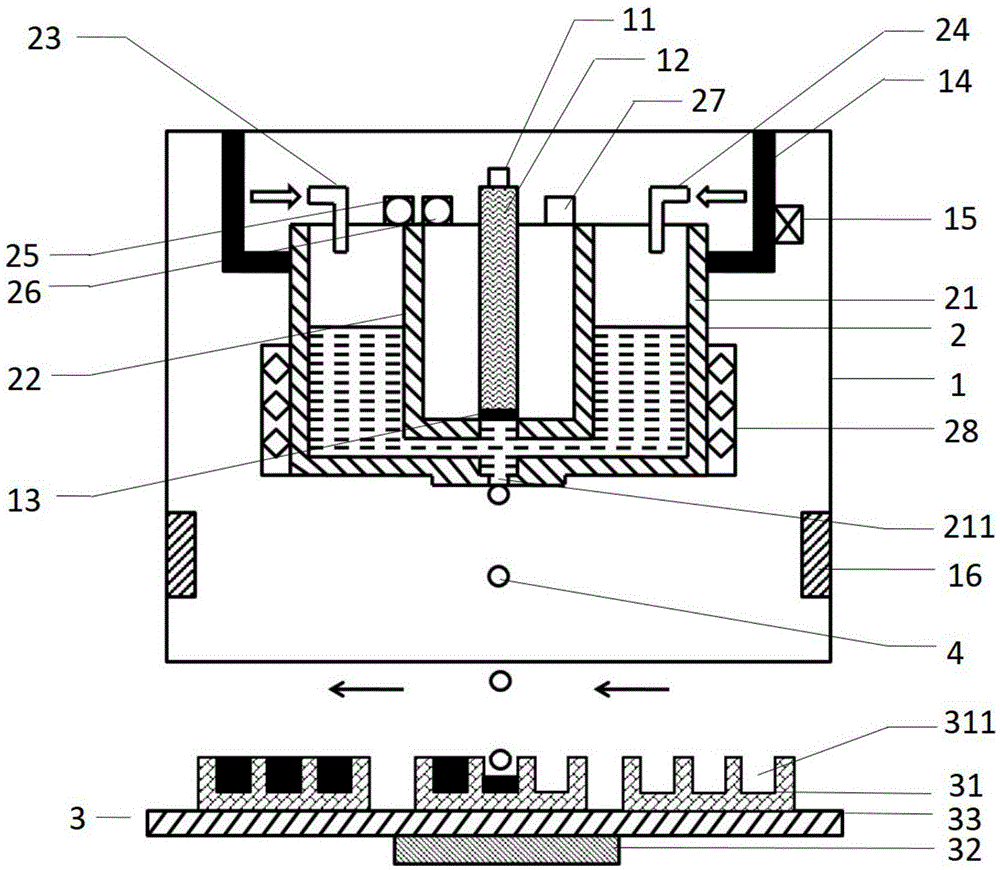

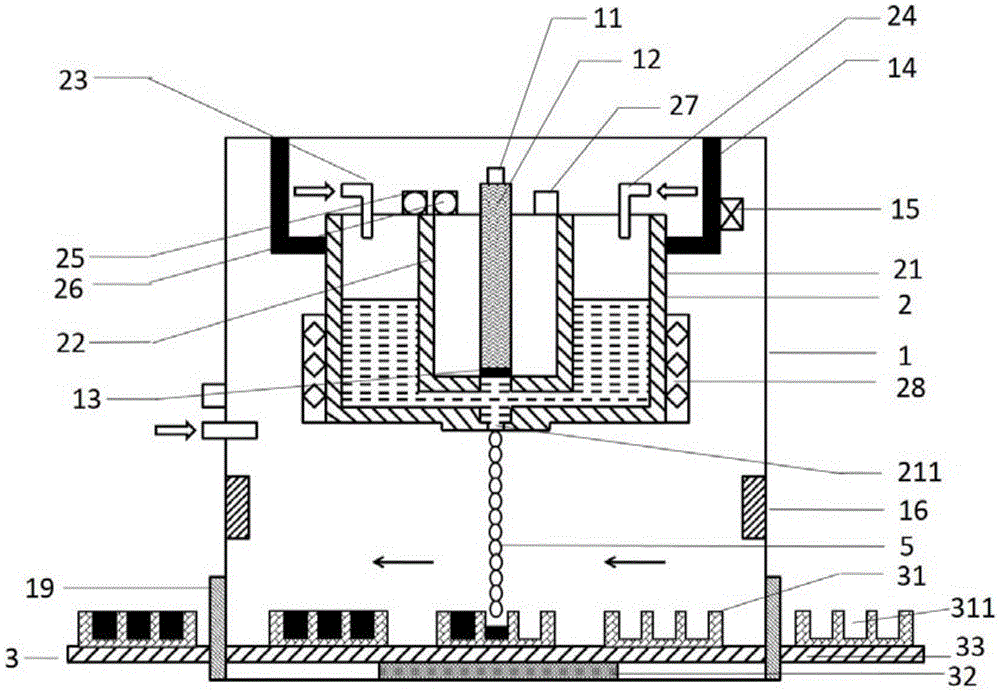

[0036] like figure 1 As shown, a filling device for three-dimensionally encapsulating vertical through holes includes a metal liquid spraying device and a filling work area 3, the metal liquid spraying device is placed on the upper part of the cavity 1, and the metal liquid spraying device includes a The sprayed crucible 2 is provided with a transmission rod 12 connected to the piezoelectric ceramic 11 inside the crucible 2, and a heating belt 28 is provided on the outside of the crucible 2. The top of the crucible 2 has a crucible air inlet I23, a crucible air inlet II 24 and a crucible exhaust port 27, the cavity 1 side has a cavity air inlet 18 and a cavity exhaust port 17, a mechanical pump 25 and a diffusion pump 26 are installed on the top of the crucible 2 and are connected to the The crucible 2 is connected to the cavity 1; during operation, the mechanical pump 25 and the diffusion pump 26 vacuumize the crucible 2 through the crucible inlet I 23 and the crucible inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com