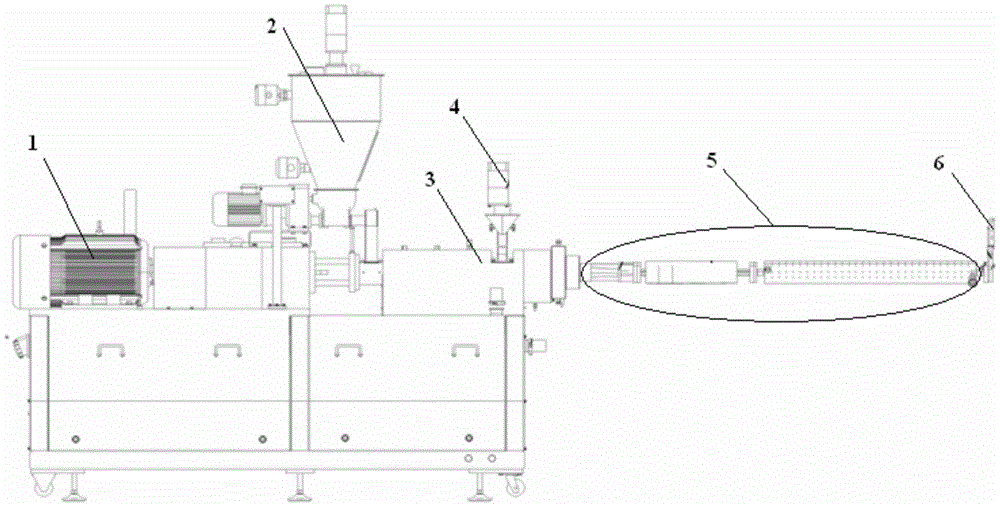

Method for continuously preparing sandwich dried bean curds on basis of double-screw extrusion machine

A twin-screw extruder and twin-screw extrusion technology, which is applied to the coating of dairy products, cheese substitutes, and food, can solve the problems of high sewage treatment costs, many labor occupations, and long processing cycles, and achieve saving Production cost, delicate surface structure, easy digestion and absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Raw material pretreatment: Soybean protein powder is subjected to impurity removal and iron removal pretreatment in sequence;

[0031] 2) Mixing: weigh the above-mentioned raw material powder, add appropriate amount of seasoning and mix evenly;

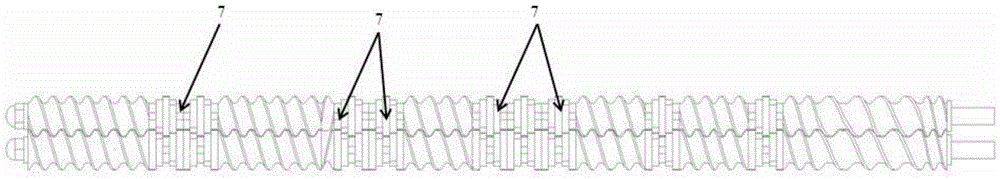

[0032] 3) Extrusion molding: Add the mixed material powder quantitatively into the twin-screw extruder, control the internal temperature of the twin-screw extrusion system to 105°C, and the pressure to 5MPa, so that the material is matured and organized under the action of screw extrusion change.

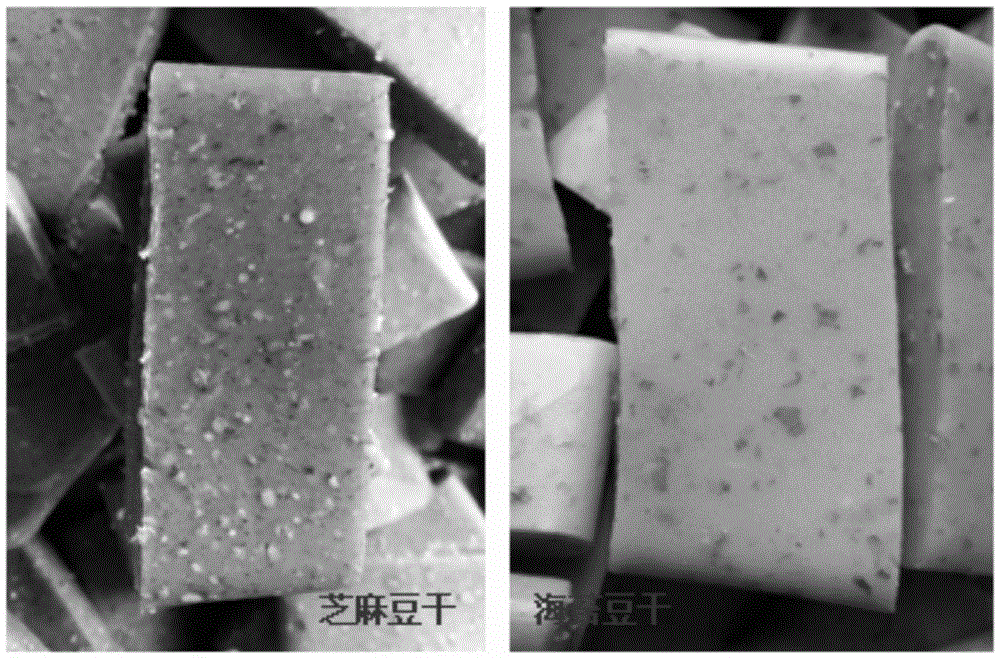

[0033] 4) Adding carrots: Carrots are added to the twin-screw extrusion system at the same time. During the conveying and compression process of the twin-screw extruder, carrots and soybean protein powder are extruded and mixed together to form carrots. The mass accounts for 10% of the mass of soybean protein powder.

[0034] 5) Forming system forming: the material first enters the forming area to be finalized, and then enters t...

Embodiment 2

[0037] 1) Raw material pretreatment: Soybean protein powder is subjected to impurity removal and iron removal pretreatment in sequence;

[0038] 2) Mixing: weigh the above-mentioned raw material powder, add appropriate amount of seasoning and mix evenly;

[0039] 3) Extrusion molding: quantitatively add the mixed material powder into the twin-screw extruder, control the internal temperature of the twin-screw extrusion system to 115°C, and the pressure to 4MPa, so that the material is matured and organized under the action of screw extrusion change.

[0040] 4) Add seaweed: Add seaweed to the twin-screw extrusion system at the same time. During the conveying and compression process of the twin-screw extruder, the seaweed and soybean protein powder are extruded and mixed together to form the seaweed material. The mass accounts for 15% of the mass of soybean protein powder.

[0041] 5) Molding system molding: The mixed material first enters the molding area to be finalized, and...

Embodiment 3

[0044] 1) Raw material pretreatment: Soybean protein powder is subjected to impurity removal and iron removal pretreatment in sequence;

[0045] 2) Mixing: weigh the above-mentioned raw material powder, add appropriate amount of seasoning and mix evenly;

[0046] 3) Extrusion molding: Add the mixed material powder quantitatively into the twin-screw extruder, control the internal temperature of the twin-screw extrusion system to 110°C, and the pressure to 5MPa, so that the material is matured and organized under the action of screw extrusion change.

[0047] 4) Adding walnuts: walnuts are added to the twin-screw extrusion system at the same time. During the conveying and compression process of the twin-screw extruder, the walnuts and soybean protein powder are extruded and mixed together to form the walnut material. The mass accounts for 15% of the mass of soybean protein powder.

[0048] 5) Molding system molding: the mixed material first enters the molding area to be finali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com