Aqueous whole oil-based color makeup composition and preparation method thereof

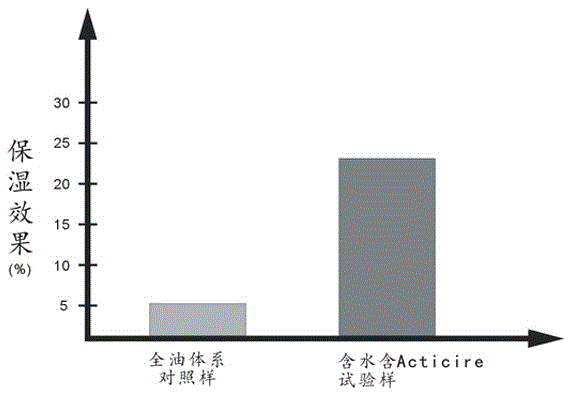

A composition and base color technology, applied in the field of daily chemicals, can solve the problems of no moisturizing feeling, unstable product system, low water content, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A water-containing lip balm, including the following components and their percentages: Acticire 5%, organic fruit water 6%, beeswax 7%, Brazilian wax 7%, candelilla wax 6%, octyldodecyl myristate 6% , essence 0.05%, caprylic / capric triglyceride balance.

[0025] The preparation method of above-mentioned water-containing lipstick mainly comprises the following steps:

[0026] (1) Heat the Acticire and the organic fruit water to 80°C respectively, put the organic fruit water into the Acticire and homogenize for 2 minutes, and let it cool naturally for use;

[0027] (2) Mix beeswax, Brazil wax, candelilla wax, octyldodecyl myristate, caprylic acid / capric triglyceride and add (2) heat to 90°C, add the mixture obtained in step (1) while stirring, Stir well and add essence at 70°C;

[0028] (3) The hot tank is cooled and formed.

Embodiment 2

[0030] A moisturizing lip oil, including the following components and their percentages: Acticire 2%, water phase containing NMF humectant (natural methylglycylaminoproline) 5%, H-100 polybutene 57.8%, white mineral Oil 15%, IPM 20%, TT antioxidant 0.06%, food flavor 0.1%.

[0031] The preparation method of above-mentioned moisturizing lip oil mainly comprises the following steps:

[0032] (1) Heat the Acticire and the water phase to 70°C respectively, add the water phase into the Acticire under continuous and rapid stirring, and homogenize completely for later use;

[0033] (2) Add H-100 polybutene, white mineral oil, and IPM into the batching pot in turn, stir and heat to 85~95°C to mix and melt evenly, then cool down to 70°C;

[0034] (3) After mixing the solution obtained in step (1) and step (2) evenly, add TT antioxidant and essence, stir evenly and cool down naturally.

Embodiment 3

[0036] A repairing and moisturizing lip gloss, including the following components and their percentages: silicon powder 6%, white oil 17.4%, 2EHP (isooctyl palmitate) 8%, white oil 10%, Acticire 2.5%, containing plants The water phase of the extracted essence is 6%, petroleum jelly 10%, microcrystalline wax 6%, squalane 2%, simethicone 3%, polybutene 240018%, toner 11%, TT antioxidant 0.1%.

[0037] The preparation method of the above-mentioned repairing and moisturizing lip gloss mainly comprises the following steps:

[0038] (1) Stir and mix silicon powder 6%, white oil, 2EHP and white oil 10, soak for 12 hours, and after grinding by a three-roll machine twice, add dimethyl silicone oil, polybutene 2400, toner and TT anti- After the oxygen agent is mixed and milled, it is used for four times;

[0039] (2) Heat the Acticire and the water phase containing the plant extract to 70°C respectively, add the water phase containing the plant extract into the Acticire under constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com