Method for modifying ultrafiltration membrane through nano-particle coating

A nanoparticle and ultrafiltration membrane technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of membrane fouling hindering the popularization and application of membrane technology, so as to improve water treatment efficiency, facilitate promotion, reduce The effect of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

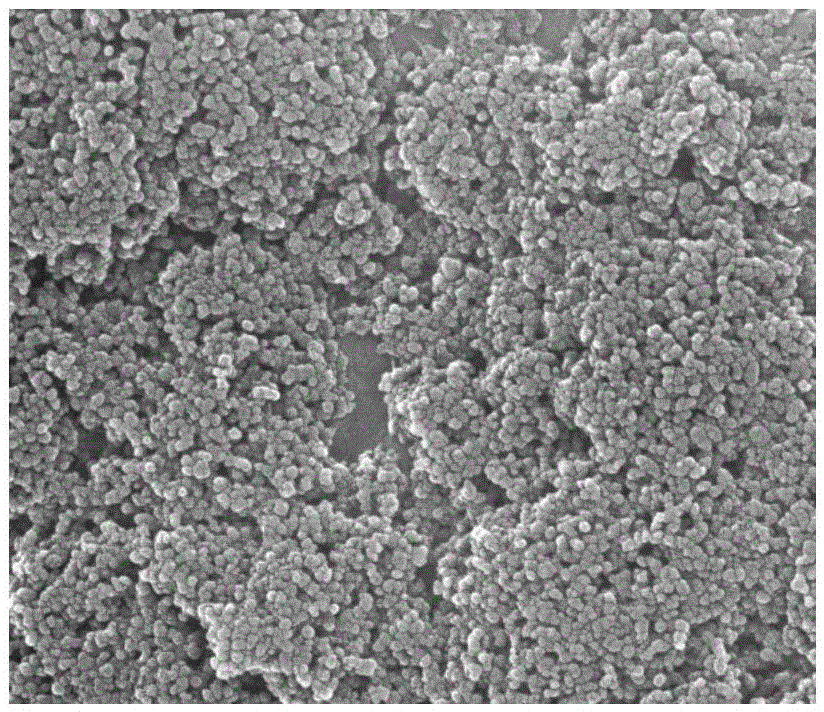

[0027] 1), add 1 milliliter of 0.5mol / L sodium bicarbonate solution to 100 milliliters of deionized water, then add 10ml of 0.1mol / L aluminum sulfate octadecahydrate, adjust the pH with 0.1mol / L sodium hydroxide solution 7±0.1, heat the solution to boil for 3min to granulate the amorphous floc in the solution, such as figure 1 As shown, the solution was left to stand for 30 minutes and the temperature was lowered to room temperature. Under the condition of constant pressure of 0.1 MPa, the particles in the solution after boiling were loaded on the surface of the polyethersulfone ultrafiltration membrane.

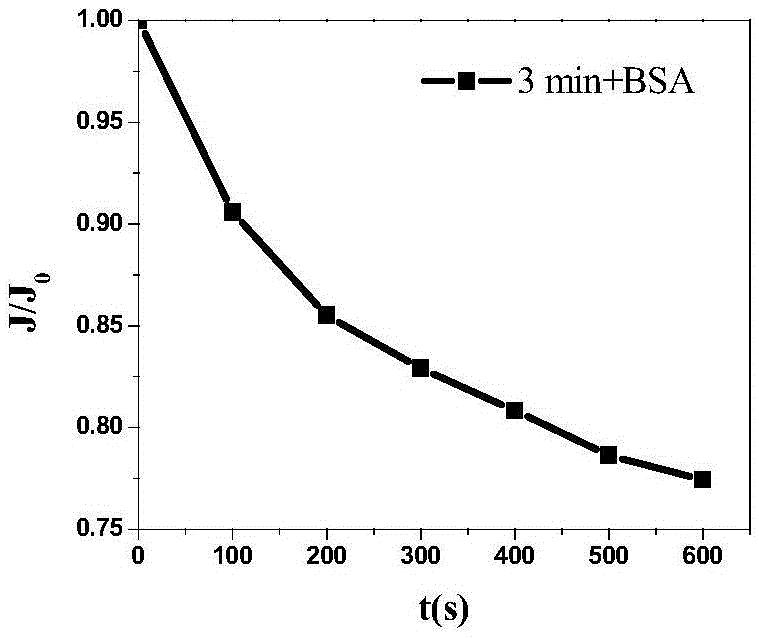

[0028] 2), 3 milliliters of 0.5mol / L sodium bicarbonate solution is added to 300 milliliters of deionized water, then add 1 milliliter of 3g / L bovine serum albumin (BSA) stock solution, adjust with 0.1mol / L hydrochloric acid solution The pH is 7 ± 0.1, the BSA solution is pre-deposited with the polyethersulfone ultrafiltration membrane ultrafiltration of 10mmol / L aluminum na...

Embodiment example 2

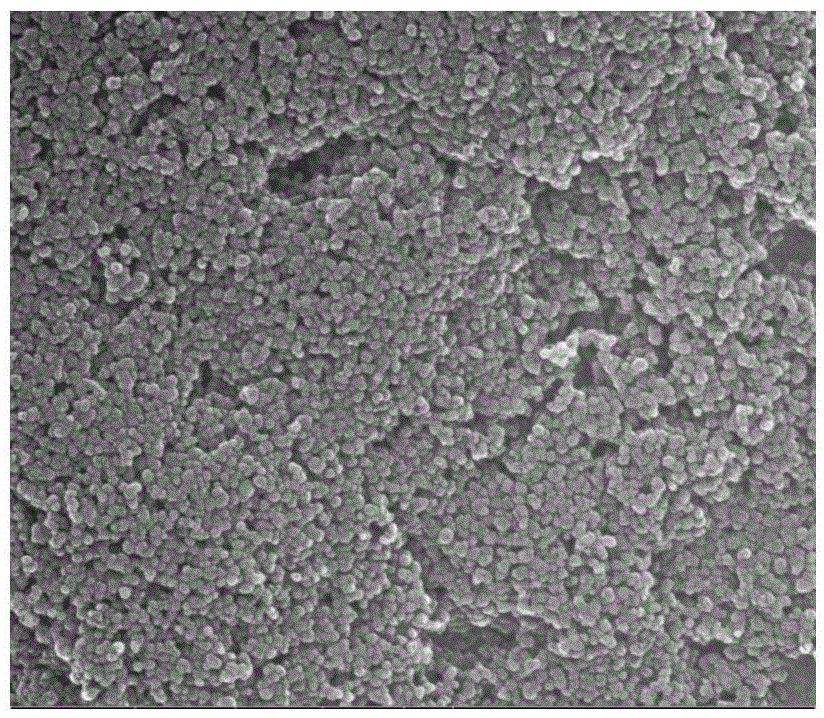

[0030] 1), add 1 milliliter of 0.5mol / L sodium bicarbonate solution to 100 milliliters of deionized water, then add 10 milliliters of octadecahydrate aluminum sulfate with a concentration of 0.1mol / L, and use 0.1mol / L sodium hydroxide solution Adjust the pH to 7±0.1, heat and boil the solution for 5 minutes to granulate the amorphous flocs in the solution, such as image 3 As shown, the solution was allowed to stand for 30 minutes to room temperature, and the particles in the solution after boiling were loaded onto the surface of the polyethersulfone ultrafiltration membrane under a constant pressure of 0.1 MPa.

[0031] 2), add 3 milliliters of 0.5mol / L sodium bicarbonate solution to 300 milliliters of deionized water, then add 1 milliliter of 3g / L HS stock solution, and adjust the pH to 7±0.1 with 0.1mol / L hydrochloric acid solution , the HS solution is pre-deposited in the above step 1) with the polyethersulfone ultrafiltration membrane ultrafiltration of 10mmol / L aluminum ...

Embodiment example 3

[0033] 1), add 1 milliliter of 0.5mol / L sodium bicarbonate solution to 100 milliliters of deionized water, then add 10 milliliters of 0.1mol / L aluminum sulfate octadecahydrate, adjust with 0.1mol / L sodium hydroxide solution The pH is 7±0.1, and the solution is heated and boiled for 10 minutes to granulate the amorphous flocs in the solution, such as Figure 5 As shown, the solution was allowed to stand for 30 minutes to room temperature, and the particles in the solution after boiling were loaded onto the surface of the polyethersulfone ultrafiltration membrane under a constant pressure of 0.1 MPa.

[0034] 2), add 3 milliliters of 0.5mol / L sodium bicarbonate solution to 300 milliliters of deionized water, then add 1 milliliter of 3g / L SA stock solution, adjust the pH to 7±0.1 with 0.1mol / L hydrochloric acid solution , the SA solution is pre-deposited with the polyethersulfone ultrafiltration membrane ultrafiltration of 10mmol / L aluminum nanoparticles in the above-mentioned st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com