Preparation method of Au@Cu2-xSe cage-like core-shell nanostructures

A technology of aucu2-xse and nanostructure, applied in the field of preparation of core-shell nanocomposite technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

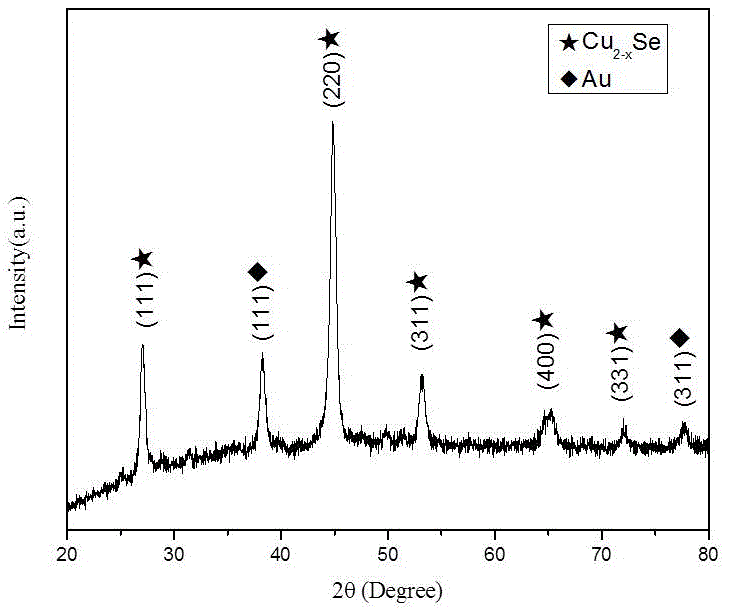

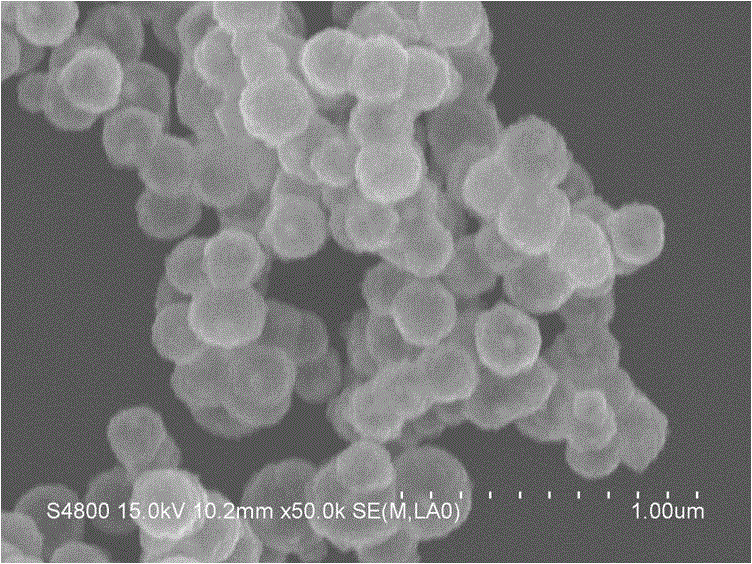

[0017] AuCu 2-x Concrete steps for the synthesis of Se cage-like core-shell nanostructures:

[0018] (1) Heat 100ml of chloroauric acid aqueous solution (0.01wt%) to boiling, then add 0.7ml of sodium citrate aqueous solution (1wt%), react under magnetic stirring for 25min, then perform centrifugation, and then disperse into 5ml of water to prepare Gold colloidal solution;

[0019] (2) To 20ml 0.01M concentration of CuSO 4 Add 0.2g of PVP (polyvinylpyrrolidone) to the solution, stir it magnetically to dissolve it, then add 2ml of gold colloidal solution, and finally add 5ml of 0.1M NaOH solution and 5ml of 0.1M AA (ascorbic acid) successively, and react for 0.5h , followed by centrifugation, and then dispersed into 5ml of water to obtain AuCu- 2 O core-shell nanocolloids;

[0020] (3) Add 0.5-1.5mmol selenium powder to 10ml 3-4M NaOH solution, ultrasonically disperse for 5-10min, then add 0.5-1.5mmol KBH 4 , stirring at 3000-6000rpm for 1-1.5h as a selenium source;

[002...

Embodiment 2

[0023] AuCu 2-x Concrete steps for the synthesis of Se cage-like core-shell nanostructures:

[0024] (1) Heat 100ml of chloroauric acid aqueous solution (0.01wt%) to boiling, then add 0.7ml of sodium citrate aqueous solution (1wt%), react under magnetic stirring for 25min, then perform centrifugation, and then disperse into 5ml of water to prepare Gold colloidal solution;

[0025] (2) To 20ml 0.01M concentration of CuSO 4 Add 0.2g of PVP (polyvinylpyrrolidone) to the solution, stir it magnetically to dissolve it, then add 4ml of gold colloidal solution, and finally add 5ml of 0.1M NaOH solution and 5ml of 0.1M AA (ascorbic acid) successively, and react for 0.5h , followed by centrifugation, and then dispersed into 5ml of water to obtain AuCu- 2 O core-shell nanocolloids;

[0026] (3) Add 0.5-1.5mmol selenium powder to 10ml 3-4M NaOH solution, ultrasonically disperse for 5-10min, then add 0.5-1.5mmol KBH 4 , stirring at 3000-6000rpm for 1-1.5h as a selenium source;

[0027]...

Embodiment 3

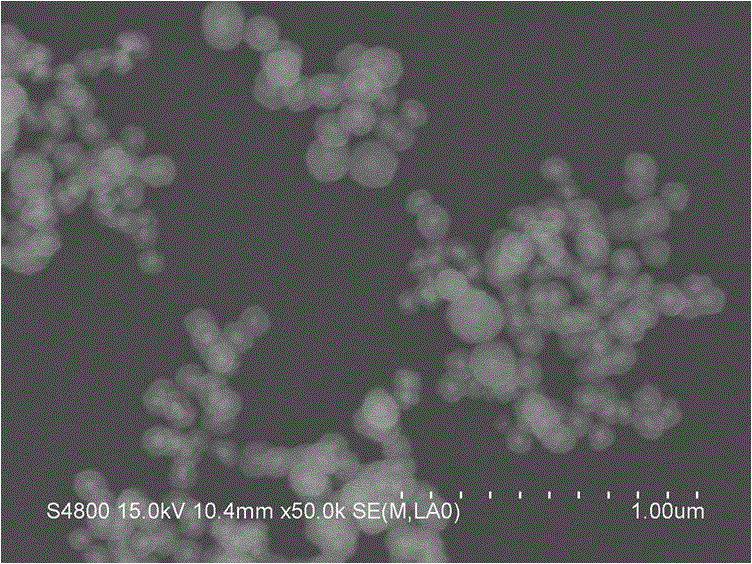

[0029] AuCu 2-x Concrete steps for the synthesis of Se cage-like core-shell nanostructures:

[0030] (1) Heat 100ml of chloroauric acid aqueous solution (0.01wt%) to boiling, then add 0.7ml of sodium citrate aqueous solution (1wt%), react for 25min under magnetic stirring, then perform centrifugation, and then disperse into 5ml of water to prepare Gold colloidal solution;

[0031] (2) To 20ml 0.01M concentration of CuSO 4 Add 0.2g of PVP (polyvinylpyrrolidone) to the solution, stir it magnetically to dissolve it, then add 2ml of gold colloidal solution, and finally add 5ml of 0.1M NaOH solution and 5ml of 0.1M AA (ascorbic acid) successively, and react for 0.5h , followed by centrifugation, and then dispersed into 5ml of water to obtain AuCu- 2 O core-shell nanocolloids;

[0032] (3) Add 0.5-1.5mmol selenium powder to 10ml 3-4M NaOH solution, ultrasonically disperse for 5-10min, then add 0.5-1.5mmol KBH 4 , stirring at 3000-6000rpm for 1-1.5h as a selenium source;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com