Horizontal type vacuum furnace for diamond particle brazing

A diamond particle, vacuum furnace technology, applied in welding equipment, metal processing equipment, electric heating devices, etc., can solve the problems of poor temperature uniformity, uneven cooling, uneven welding, etc., achieve rapid cooling, ensure brazing quality, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

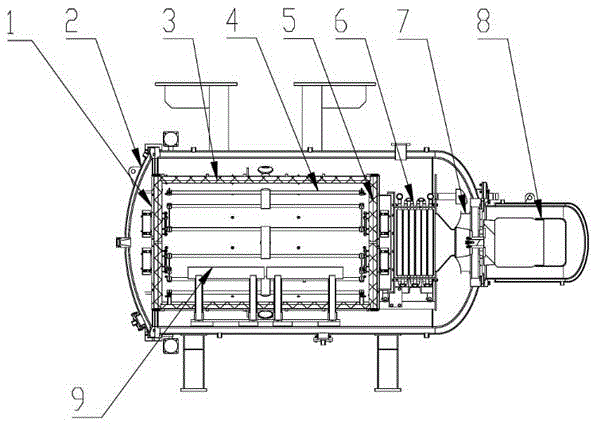

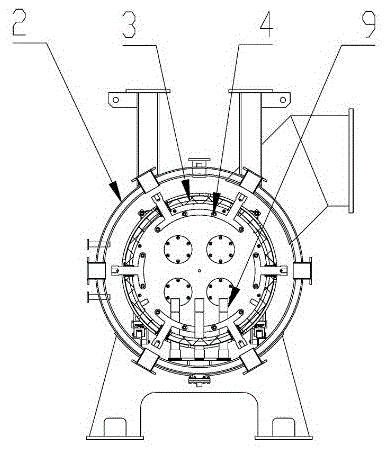

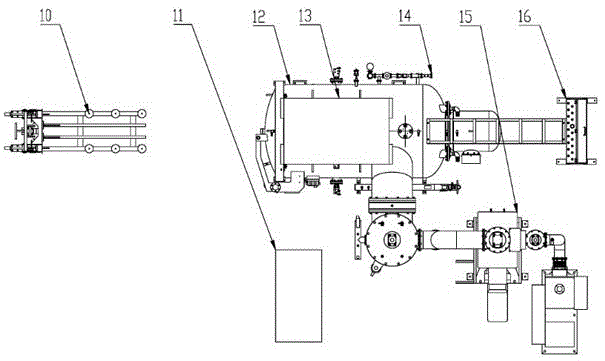

[0010] The present invention will be further described below with reference to the accompanying drawings.

[0011] The horizontal vacuum furnace for diamond particle brazing of the present invention adopts a circular horizontal vacuum shell and a furnace door 2 structure, one side is equipped with a furnace door, an inner and outer double-layer design structure, water cooling between the double layers, and a heating chamber It is a cylindrical structure, installed in a vacuum shell, using a graphite tubular heater 4 structure, using upper and lower heating, with a temperature compensation structure at the front and rear ends, the thermal insulation material is used once to form a cylindrical hard carbon felt as the inner tank, The exterior is wrapped with soft carbon felt; both ends of the cylindrical heating chamber are door panels of the same structure, and are equipped with 4 air vents. The air vents are provided with a thermal insulation structure to prevent temperature los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com