Non-woven cloth and non-woven cloth bag

A technology of non-woven fabrics and anti-mildew agents, applied in sacks, containers, biocides, etc., can solve the problems of lack of anti-mildew ability, affecting the appearance of products, and peculiar smell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of mildew-proof microcapsules: take by weighing 250g chitosan, 40g octadecyldimethyl (3-methoxysilyl propyl) ammonium chloride and 60g eugenol, above-mentioned raw material is passed microcapsule conventional method ( Such as polymerization reaction method, phase separation method, physical and mechanical method) to make anti-mildew microcapsule powder.

[0022] Preparation of anti-mildew layer: Mix the obtained anti-mildew microcapsule powder with glue, evenly spray or coat it on a sheet (paper sheet or film) to obtain an anti-mildew layer loaded with anti-mildew microcapsules. Since the anti-mold layer is loaded with anti-mold microcapsules, the anti-mold microcapsules can slowly release the anti-mold agent, thus greatly improving the effective anti-mold time of the anti-mold layer.

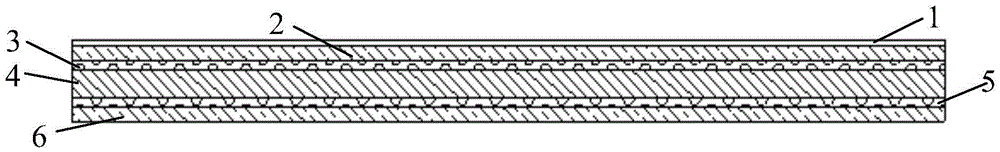

[0023] Such as figure 1 The non-woven fabric shown includes a 6-layer structure, the middle layer is a non-woven fabric layer 4, and the two sides of the non-woven fabri...

Embodiment 2

[0026] The preparation of mildew-resistant microcapsules: take by weighing 500g beta-cyclodextrin, 80g octadecyl dimethyl benzyl ammonium chloride and 100g thymol, the above-mentioned raw materials are passed microcapsule conventional method (such as polymerization reaction method, phase separation method, physical and mechanical method) to make anti-mildew microcapsule powder.

[0027] Preparation of the anti-mildew layer: the obtained anti-mold microcapsule powder is mixed with glue, and directly made into a sheet to obtain the anti-mold layer loaded with the anti-mold microcapsules.

[0028] Such as figure 1 The non-woven fabric shown includes a 6-layer structure, the middle layer is a non-woven fabric layer 4, and the two sides of the non-woven fabric layer 4 are respectively bonded with the first mildew-proof layer 3 and the second mildew-proof layer prepared in this embodiment 5. The first moisture-proof layer 2 is provided on the outside of the first mildew-proof layer...

Embodiment 3

[0031] The preparation of mildew-proof microcapsules: take by weighing 300g methyl methacrylate, 140g octadecyltrimethylammonium chloride and 300g triclosan, above-mentioned raw material is passed microcapsule conventional method (such as polymerization reaction method, phase separation method) , physical and mechanical methods) to make anti-mildew microcapsule powder.

[0032] Preparation of the anti-mildew layer: after mixing the obtained anti-mold microcapsule powder with glue, immerse the sponge into the above-mentioned mixture and take it out to obtain the anti-mold layer loaded with the anti-mold microcapsules.

[0033] Such as figure 1 The non-woven fabric shown includes a 6-layer structure, the middle layer is a non-woven fabric layer 4, and the two sides of the non-woven fabric layer 4 are respectively bonded with the first mildew-proof layer 3 and the second mildew-proof layer prepared in this embodiment 5. The first moisture-proof layer 2 is provided on the outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com