A kind of easy peel film for medical packaging and preparation method thereof

A heat-sealing layer, ethylene technology, applied in the field of medical packaging materials, can solve the problems of easy migration into the packaging or adsorption by the packaging, the existence of drug safety risks, and the increase of film leaching substances, so as to reduce the treatment and drug safety risks. , to avoid particles and other pollution, the effect of low haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

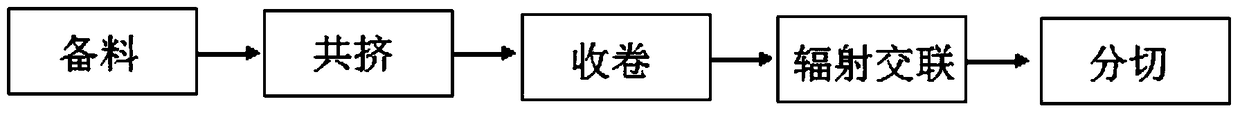

Method used

Image

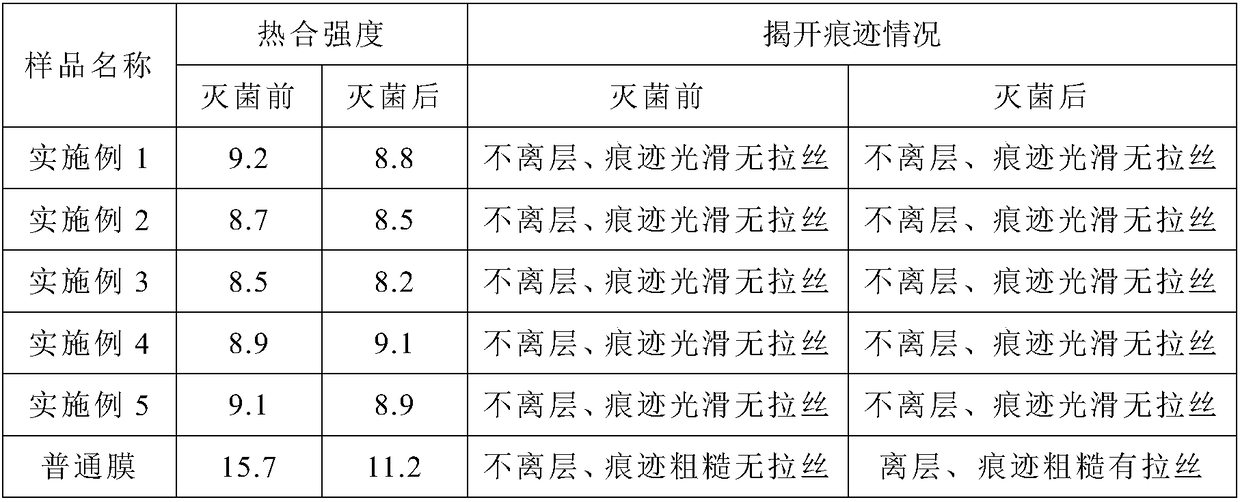

Examples

Embodiment 1

[0035] Embodiment 1: A kind of raw material component of easy peel-off film of medical packaging (substance measurement unit is all by weight percentage):

[0036] (1) heat sealing layer: polyethylene 30%, ethylene-vinyl acetate 40%, ethylene-methyl acrylate 30%, the melt flow index (190 ℃, 2.16kg) of polyethylene in the described heat sealing layer is 0.5g / 10min, melting point 80~120℃, density 0.89g / cm 3 The melt flow index (190°C, 2.16kg) of ethylene-vinyl acetate in the heat-sealing layer is 0.5g / 10min, wherein the vinyl acetate content is 5%; the melt flow index of ethylene-methyl acrylate in the heat-sealing layer The melt flow index (190°C, 2.16kg) is 0.5g / 10min, wherein the methyl acrylate content is 10%;

[0037] (2) Structural layer: polyethylene, the melt flow index (190°C, 2.16kg) of the polyethylene is 0.3g / 10min, the melting point is 90°C, and the density is 0.89g / cm 3 ;

[0038] (3) Adhesive layer: maleic anhydride modified ethylene octene copolymer, the melt...

Embodiment 2

[0043] Embodiment 2: A kind of raw material component of medical packaging easy-to-remove film (substance measurement unit is all by weight percentage):

[0044] (1) heat sealing layer: polyethylene 80%, ethylene-vinyl acetate 10%, ethylene-methyl acrylate 10%, the melt flow index (190 ℃, 2.16kg) of polyethylene in the heat sealing layer is 10g / 10min , with a melting point of 120°C and a density of 0.94g / cm 3 The melt flow index (190°C, 2.16kg) of ethylene-vinyl acetate in the heat-sealing layer is 5g / 10min, wherein the vinyl acetate content is 30%; the melt flow index of ethylene-methyl acrylate in the heat-sealing layer Body flow index (190°C, 2.16kg) is 10g / 10min, and the content of methyl acrylate is 35%;

[0045] (2) Structural layer: polyethylene, the melt flow index (190°C, 2.16kg) of the polyethylene is 8g / 10min, the melting point is 125°C, and the density is 0.96g / cm 3 ;

[0046] (3) Adhesive layer: maleic anhydride modified ethylene octene copolymer, the melt flow...

Embodiment 3

[0051] Embodiment 3: A kind of raw material component of easy peel-off film of medical packaging (substance measurement unit is all by weight percentage):

[0052] (1) heat sealing layer: polyethylene 50%, ethylene-vinyl acetate 30%, ethylene-methyl acrylate 20%, the melt flow index (190 ℃, 2.16kg) of polyethylene in the heat sealing layer is 8g / 10min , with a melting point of 80-120°C and a density of 0.9g / cm 3 The melt flow index (190°C, 2.16kg) of ethylene-vinyl acetate in the heat-sealing layer is 3g / 10min, wherein the vinyl acetate content is 20%; the melt flow index of ethylene-methyl acrylate in the heat-sealing layer The body flow index (190°C, 2.16kg) is 5g / 10min, and the content of methyl acrylate is 20%;

[0053] (2) Structural layer: polyethylene, the melt flow index (190°C, 2.16kg) of the polyethylene is 5g / 10min, the melting point is 100°C, and the density is 0.91g / cm 3 ;

[0054] (3) Adhesive layer: maleic anhydride modified ethylene octene copolymer, the mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com