Thermoplastic elastomer for infusion bag and preparation method thereof

A thermoplastic elastomer and thermoplastic elastomer technology, applied in the field of thermoplastic elastomer and its preparation, can solve the problems of increasing the difficulty of lamp inspection, environmental impact of dioxins, inability to reach infusion bags, etc., so as to avoid pollution and degradation of polymer materials. , The effect of reducing drug safety risks and improving sterility guarantee value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

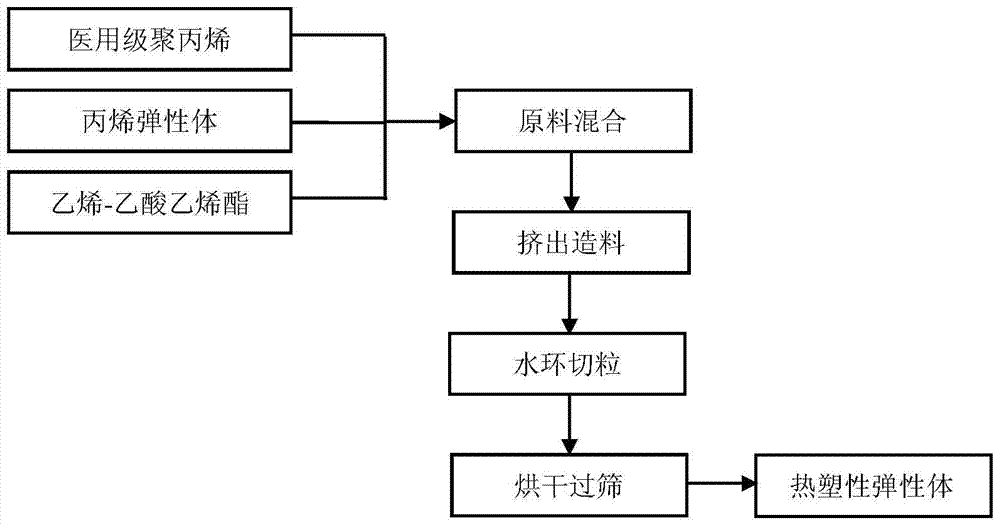

[0032] A kind of thermoplastic elastomer preparation method for infusion bag of the present invention comprises the following steps:

[0033] (1), above-mentioned raw material is weighed according to weight percentage;

[0034] (2) Mix the weighed raw materials evenly in a high-speed mixer, and the mixing time is 3-6min;

[0035] (3) Extrude the mixed raw materials through a twin-screw extruder to make materials. The melting temperature of the materials is 170-210°C, and the screw speed is 250-400rpm; Thermoplastic elastomers for infusion bags are available.

[0036] According to the content of components, mixing time, extrusion temperature and screw speed, the thermoplastic elastomer of the present invention and its preparation method can have many different implementations, and Table 1 shows the selected examples of four combinations.

[0037] Table 1 The specific implementation of various formulation processes

[0038] A component content B component conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com