Electrogenic desalting device based on electronic regulation and control and method for treating ammonium sulfate-containing ptetrochemical wastewater by using device

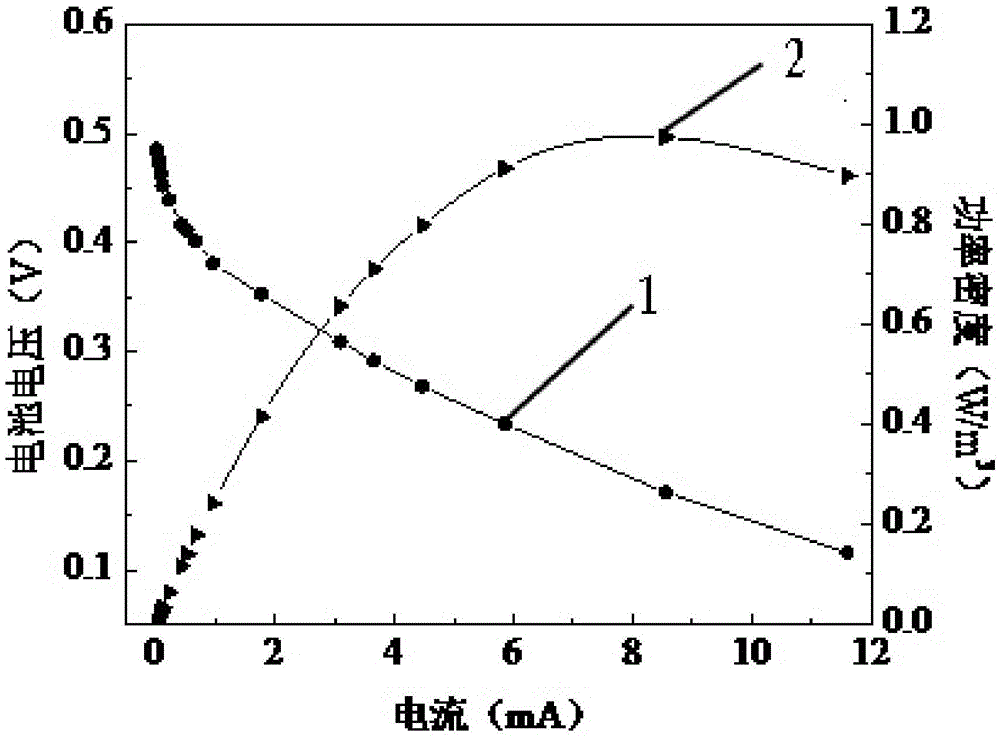

A refinery wastewater and electric desalination technology, which is applied in chemical instruments and methods, electrochemical and biological combined treatment, biological water/sewage treatment, etc., can solve the problems of difficult biochemical treatment, energy waste of industrial wastewater, and difficult industrial wastewater treatment, etc. problem, to achieve the effect of obvious and stable power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

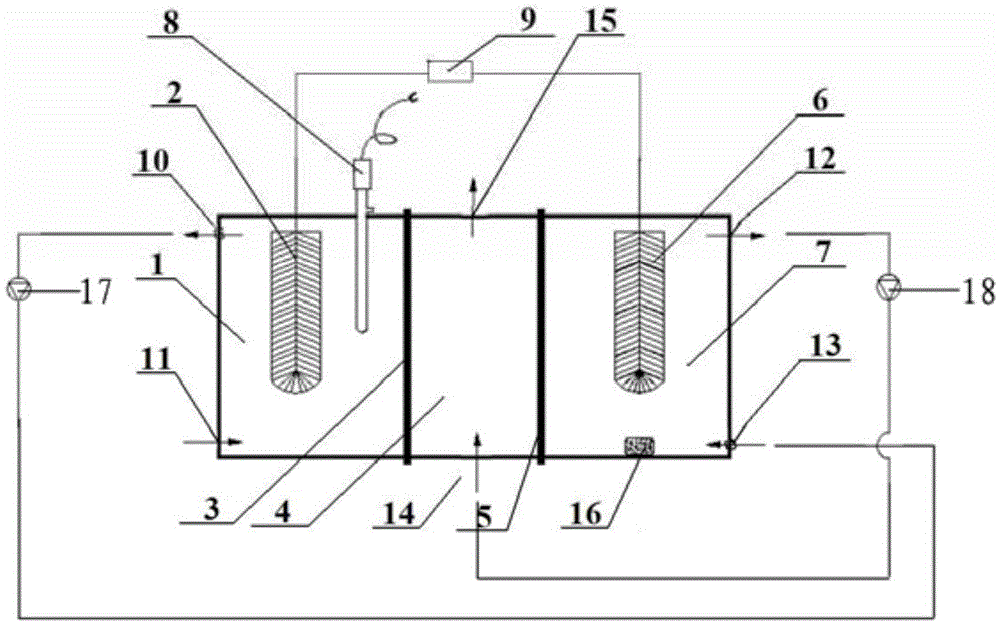

[0019] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the electricity generation and desalination device based on electronic control in this embodiment includes an anode chamber 1, an anode carbon brush 2, an anion exchange membrane 3, a desalination chamber 4, a cation exchange membrane 5, a cathode carbon brush 6, a cathode chamber 7, Reference electrode 8, external resistance 9 and aeration device 16; the desalination chamber 4 is arranged between the anode chamber 1 and the cathode chamber 7, and the left side of the desalination chamber 4 and the right side of the anode chamber 1 pass through an anion exchange membrane 3, the right side of the desalination chamber 4 is separated from the left side of the cathode chamber 7 by a cation exchange membrane 5; A water outlet 10, a first water inlet 11 is arranged on the lower left side of the anode chamber 1, and the reference electrode 8 penetrates through the upper wall of the anode chamber ...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the volumes of the anode chamber 1 and the cathode chamber 7 are the same. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

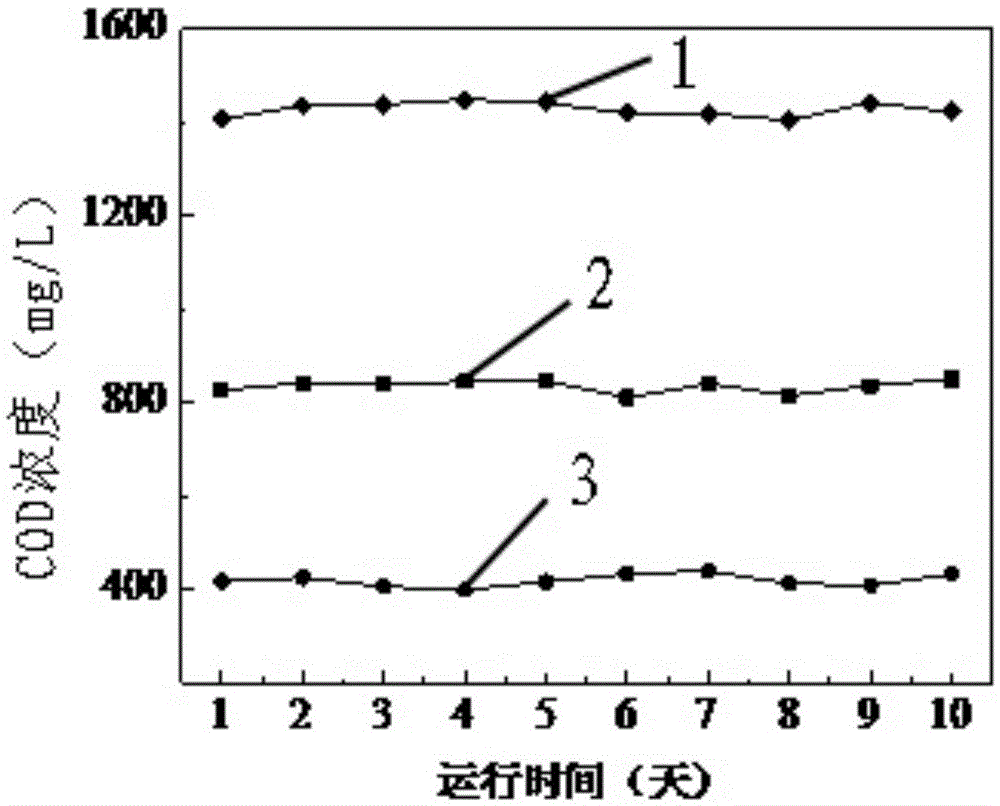

[0021] Specific Embodiment Three: The method of using the electronic regulation-based power generation desalination device of the present embodiment to treat sulfur-containing ammonium refinery wastewater is specifically carried out according to the following steps:

[0022] 1. Inject activated sludge capable of degrading refining wastewater into the anode chamber 1 and cathode chamber 7, respectively, and then add sulfur-containing ammonium refinery wastewater to the anode chamber 1 and cathode chamber 7 respectively until the anode chamber 1 is sealed. 18h-26h, the cathode chamber 7 is continuously aerated by the aeration device 16 for 18h-26h, and then the sulfur-containing ammonium refining waste water in the anode chamber 1 and cathode chamber 7 is discharged;

[0023] 2. Use an external resistor 9 to connect the anode carbon brush 2 and the cathode carbon brush 6, and then add PBS buffer solution to the anode chamber 1 and the cathode chamber 7 to a concentration of 18ppm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com