A kind of thickening powder specially used for mechanical spraying mortar

A technology of mechanical spraying and thickened powder, which is applied in the field of building materials, can solve the problems of rising labor costs, low construction efficiency, astonishing material consumption, etc., and achieve the effects of long storage period, good effect, outstanding economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

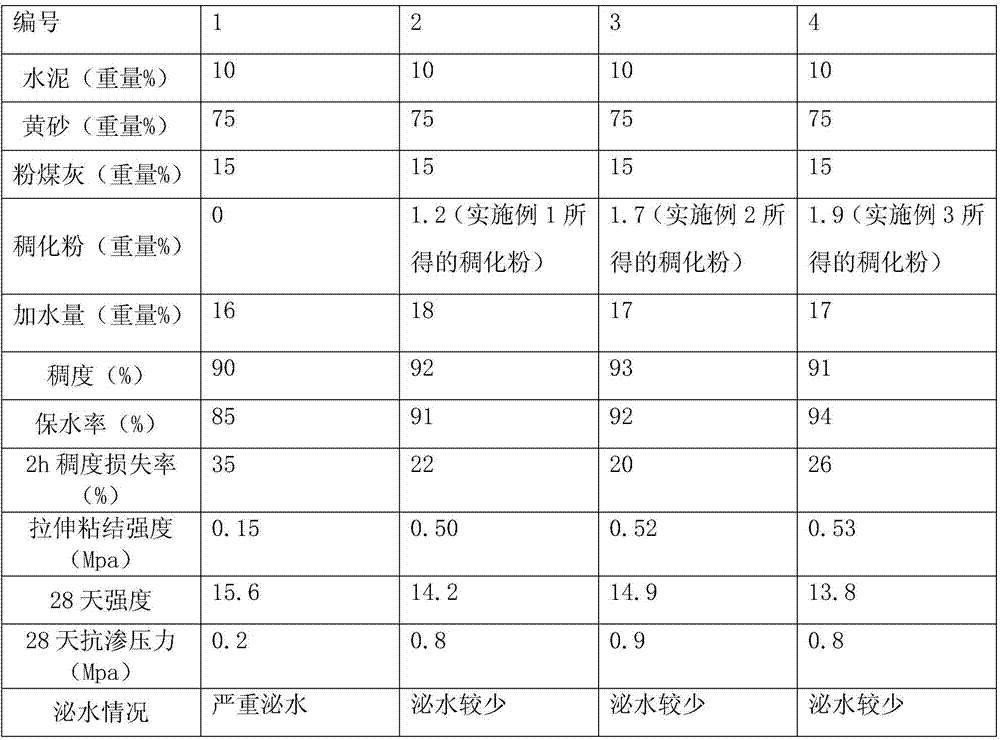

Examples

Embodiment 1

[0048] Composition and proportioning and preparation of embodiment 1 thickened powder

[0049] A thickening powder specially used for mechanical spraying mortar, including 5 parts of modified cellulose ether, 300 parts of kaolin, 2 parts of air-entraining agent, 2 parts of foam stabilizer, 10 parts of naphthalene-based water reducer, modified polyvinyl alcohol 6 parts, 5 parts of wood fiber, 20 parts of polyethylene oxide, 20 parts of modified latex powder, and 626 parts of fly ash. The preparation method is to mix each component according to the weight parts.

Embodiment 2

[0050] Embodiment 2 Composition, proportioning and preparation of thickened powder dedicated to mechanical spraying mortar

[0051] A thickening powder specially used for mechanical spraying mortar, including 7.5 parts of modified cellulose ether, 400 parts of kaolin, 1 part of air-entraining agent, 1 part of foam stabilizer, 6 parts of naphthalene-based water reducer, modified polyvinyl alcohol 10 parts, 10 parts of wood fiber, 5 parts of polyethylene oxide, 50 parts of modified latex powder, and 509.5 parts of fly ash. The preparation method is to mix the components according to the stated parts by weight.

Embodiment 3

[0052] Embodiment 3 Composition, proportioning and preparation of thickened powder specially used for mechanical spraying mortar

[0053] A thickening powder specially used for mechanical spraying mortar, including 7 parts of modified cellulose ether, 380 parts of kaolin, 1 part of air-entraining agent, 3 parts of foam stabilizer, 8 parts of naphthalene-based water reducer, modified polyvinyl alcohol 8 parts, 6 parts of wood fiber, 12 parts of polyethylene oxide, 28 parts of modified latex powder, and 547 parts of fly ash. The preparation method is to mix each component according to the weight parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com