A kind of purification method of long-chain dicarboxylic acid

The technology of a long-chain dicarboxylic acid and a purification method is applied in the purification field of long-chain dicarboxylic acid, which can solve the problems of low yield of dicarboxylic acid product, low alkane recovery rate, complicated operation steps, etc., and achieves equipment saving and purity. The effect of high and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

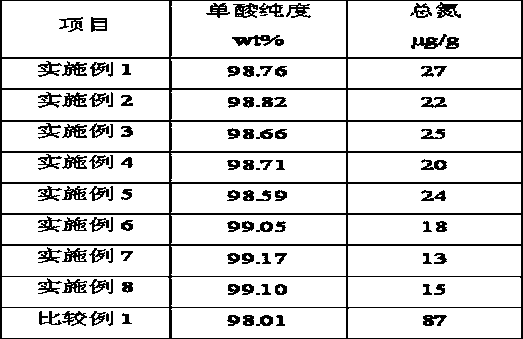

Examples

Embodiment 1

[0026] Using n-dodecane as substrate, use Candida tropicalis to ferment and produce dodecanedicarboxylic acid. At the end of the fermentation, the dicarboxylic acid concentration was 164.3 g / L and the pH was 7.4. Take 1000ml of fermentation broth, heat it to 80°C, let it stand for 2 hours, recover unreacted alkanes in the upper layer, and use a membrane with a pore size of 10 -2 Filter through a μm membrane to remove bacterial cells and debris. Add 5% polyethylene glycol with a mass fraction of 4000 molecular weight and 8% dextran with a molecular weight of 300 000 to the fermentation broth, and stir to dissolve each substance in the fermentation broth to form an aqueous two-phase system. Send the system into the high-gravity equipment for high-gravity treatment. The high-gravity level is 150g, and the average residence time of the high-gravity treatment is 5s. The system after the high-gravity treatment is left still for 20 minutes. The upper and lower phases are separated, ...

Embodiment 2

[0028] Using n-dodecane as substrate, use Candida tropicalis to ferment and produce dodecanedicarboxylic acid. At the end of the fermentation, the dicarboxylic acid concentration was 158 g / L and the pH was 7.3. Take 1000ml of fermentation broth, heat it to 95°C, let it stand for 2h, recover the unreacted alkanes in the upper layer, and use a membrane with a pore size of 10 -1 μm microfiltration membrane to remove bacterial cells and debris. 3% polyethylene glycol with a molecular weight of 20,000 and 5% dextran with a molecular weight of 500,000 were added to the fermentation broth, and stirred to dissolve each substance in the fermentation broth to form an aqueous two-phase system. Send the system into the high-gravity equipment for high-gravity treatment. The high-gravity level is 200g, and the average residence time of the high-gravity treatment is 8s. The system after the high-gravity treatment is left still for 30 minutes, the upper and lower phases are separated, and th...

Embodiment 3

[0030] Using n-tridecane as substrate, use Candida tropicalis to ferment and produce tridecanedicarboxylic acid. At the end of the fermentation, the dicarboxylic acid concentration was 154.3 g / L and the pH was 7.5. Take 1000ml of fermentation broth, heat it to 80°C, let it stand for 2 hours, recover unreacted alkanes in the upper layer, and use a membrane with a pore size of 10 -2 μm ultrafiltration membrane to remove bacterial cells and debris. 4% polyethylene glycol with a molecular weight of 10 000 and 6% dextran with a molecular weight of 400 000 were added to the fermentation broth, and stirred to dissolve the substances in the fermentation broth to form an aqueous two-phase system. Send the system into the high-gravity equipment for high-gravity treatment. The high-gravity level is 300g, and the average residence time of the high-gravity treatment is 3s. The system after the high-gravity treatment is left still for 30 minutes. The upper and lower phases are separated, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com