Preparing method for synthesizing shape-controlled anisotropic particles through emulsion polymerization based on asymmetry monomer-swelling non-crosslinking seed particles

An anisotropic and emulsion polymerization technology, which is applied in the field of preparation of shape-controlled anisotropic particles based on emulsion polymerization of asymmetric monomers-swollen non-crosslinked seed particles, achieving the promotion of theoretical and technological development and wide application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

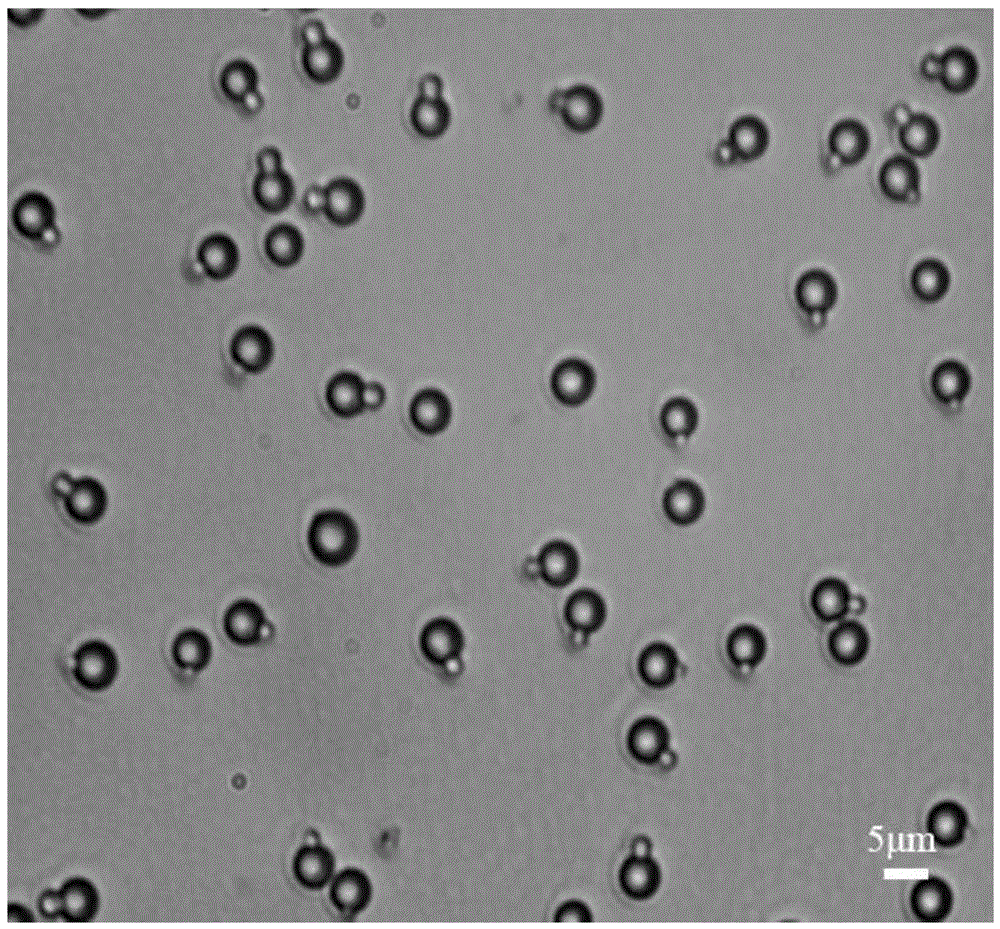

[0034] Example 1: Preparation of morphology-controllable anisotropic particles based on emulsion polymerization of asymmetric monomer-swelling non-crosslinked seed particles

[0035] (1) Preparation of monodisperse polyglycidyl methacrylate (PGMA) polymer seeds:

[0036] Prepare a polyvinylpyrrolidone alcohol / water solution with a mass fraction of 7%, wherein the volume ratio of alcohol to water is 10:1, and put it in a three-necked bottle equipped with a mechanical stirring and condensing device; add methyl alcohol dissolved in an initiator to the above solution. Glycidyl acrylate (GMA), wherein the initiator accounts for 1.0% of the GMA mass, and the volume ratio of GMA and alcohol / water solution is 1:7; then the system is warmed up to 80°C, and reacted for 12h under 100r / min mechanical stirring; The resulting product was washed three times with ethanol and water respectively, and dried to obtain PGMA polymer seeds;

[0037] (2) Preparation of asymmetric monomer-swelling pa...

Embodiment 2

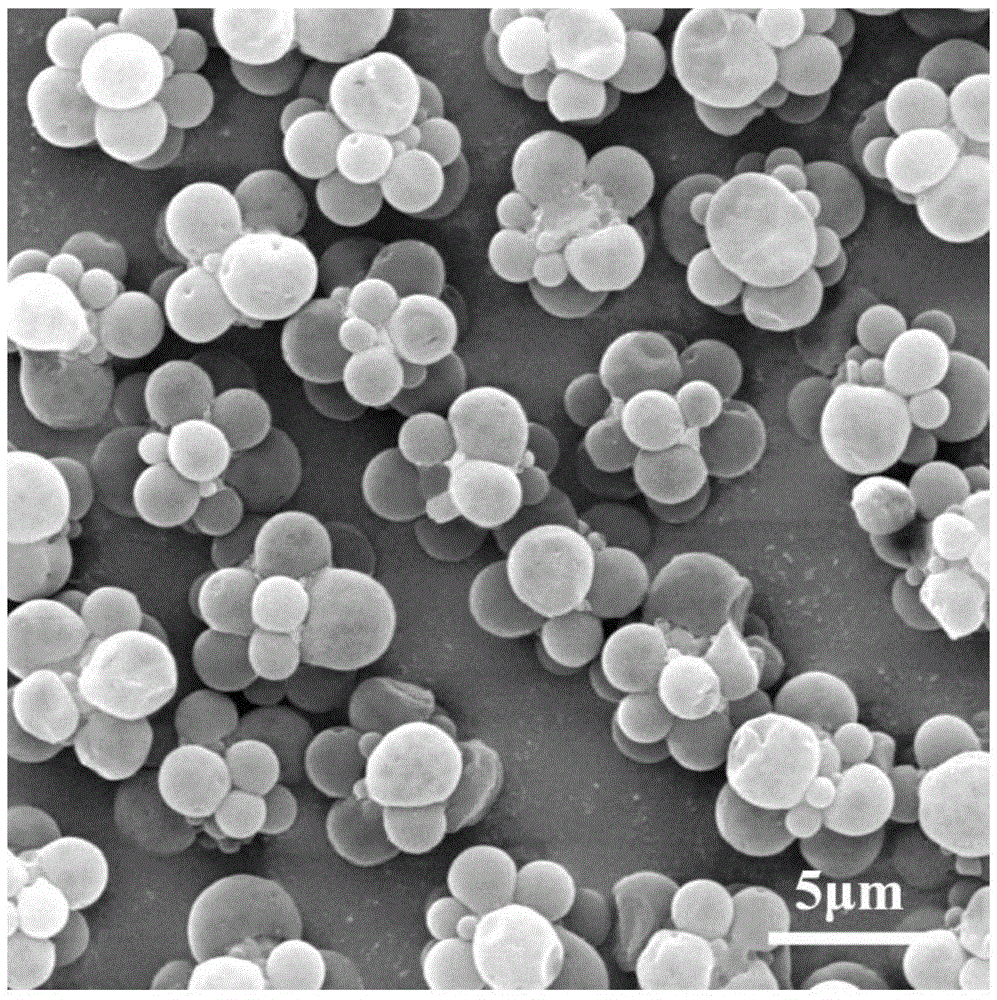

[0041] Example 2: Preparation of morphology-controllable anisotropic particles based on emulsion polymerization of asymmetric monomer-swelling non-crosslinked seed particles

[0042] (1) Preparation of monodisperse polyglycidyl methacrylate (PGMA) polymer seeds:

[0043] Prepare a polyvinylpyrrolidone alcohol / water solution with a mass fraction of 2%, wherein the volume ratio of alcohol to water is 2:1, and put it in a three-necked bottle equipped with a mechanical stirring and condensing device; add methyl alcohol dissolved in an initiator to the above solution Glycidyl acrylate (GMA), wherein the initiator accounts for 0.5% of the GMA mass, and the volume ratio of GMA and alcohol / water solution is 1:7; then the system is warmed up to 80°C and reacted for 12h under 100r / min mechanical stirring; The resulting product was washed three times with ethanol and water respectively, and dried to obtain PGMA polymer seeds;

[0044] (2) Preparation of asymmetric monomer-swelling parti...

Embodiment 3

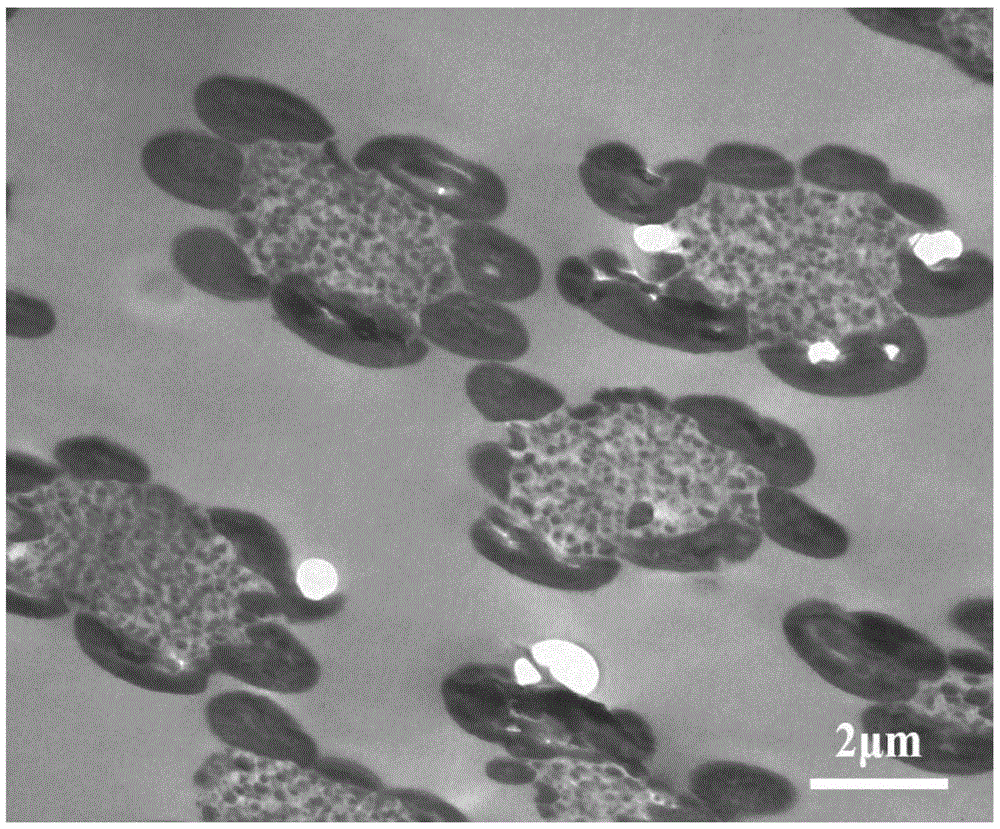

[0048] Example 3: Preparation of morphology-controllable anisotropic particles based on emulsion polymerization of asymmetric monomer-swelling non-crosslinked seed particles

[0049] (1) Preparation of monodisperse polyglycidyl methacrylate (PGMA) polymer seeds:

[0050] Prepare a polyvinylpyrrolidone alcohol / water solution with a mass fraction of 5%, wherein the volume ratio of alcohol to water is 9:1, and put it in a three-necked bottle equipped with a mechanical stirring and condensation device; add methyl alcohol dissolved in the initiator to the above solution. Glycidyl acrylate (GMA), wherein the initiator accounts for 1.0% of the GMA mass, and the volume ratio of GMA and alcohol / water solution is 1:5; then the system is warmed up to 80°C, and reacted for 8h under 200r / min mechanical stirring; The resulting product was washed three times with ethanol and water respectively, and dried to obtain PGMA polymer seeds;

[0051] (2) Preparation of asymmetric monomer-swelling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com