Casting nylon/graphene nanocomposite material and preparation method thereof

A technology of nanocomposite materials and cast nylon, which is applied in the field of polymers to achieve related performance improvements and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Put 500g of caprolactam in a 1000ml three-necked flask, heat it to about 80°C, and make it completely melted, then add 5mg of graphene powder, and disperse in an ultrasonic pulverizer for 20 minutes (power is 20%), Graphene is completely dispersed in the molten caprolactam monomer to form a mixed melt;

[0030] (2) Heat the mixed melt to 150°C, vacuumize and remove water for 30 minutes, then add 5g of sodium hydroxide and 2.5ml of 2,4-toluene diisocyanate (TDI), mix well, and open the solution by in-situ anion The ring polymerization process is used for casting, and the mold temperature is controlled at 160°C. After reacting for 15 minutes, it is cooled to obtain a cast nylon / pure graphene nanocomposite material.

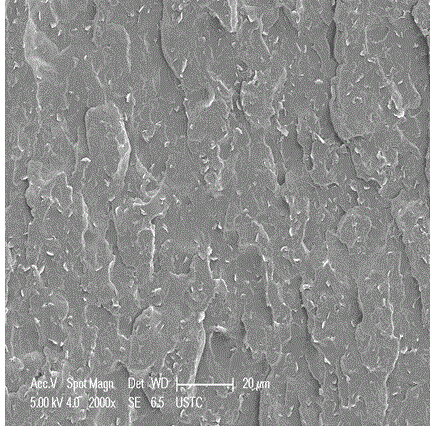

[0031] The electron microscope scanning image of the prepared cast nylon / pure graphene nanocomposite is as follows: figure 1 As shown, it can be seen from the figure that the dispersion of graphene in the matrix caprolactam is uniform and the dispersion ...

Embodiment 2

[0034] The preparation process and raw materials are the same as in Example 1, except that the addition of graphene powder is changed to 50 mg.

Embodiment 3

[0036] The preparation process and raw materials are the same as in Example 1, except that the addition of graphene powder is changed to 500 mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com