Ultra-high density oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid, ultra-high-density technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that it is difficult to adapt to long-term drilling and completion requirements, and the drilling displacement cannot meet the requirements of purifying the wellbore. , rheology and suspension ability are difficult to coordinate and other problems, to achieve good emulsion stability, expand the range of density use, and low preparation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

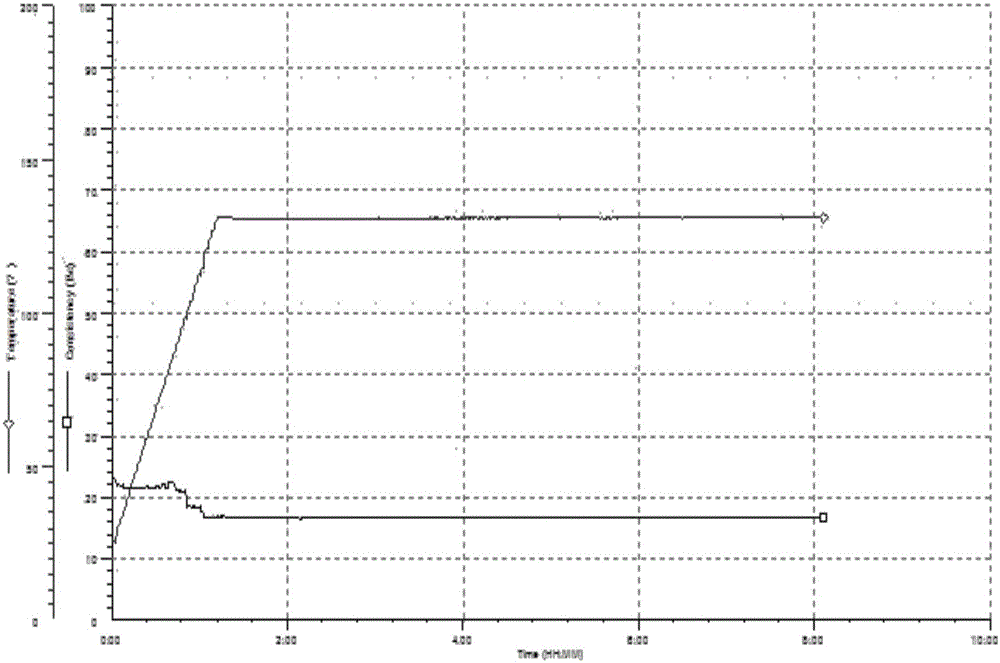

Image

Examples

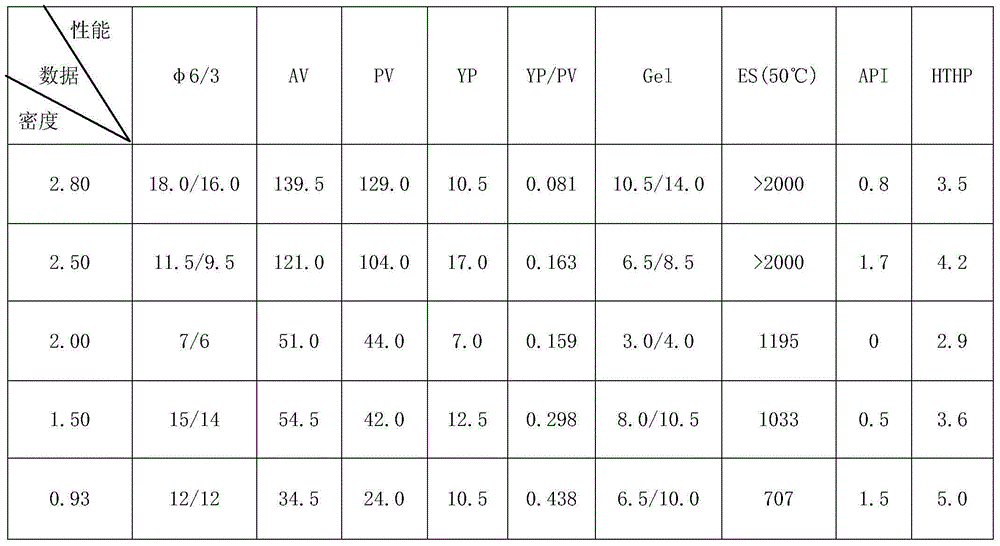

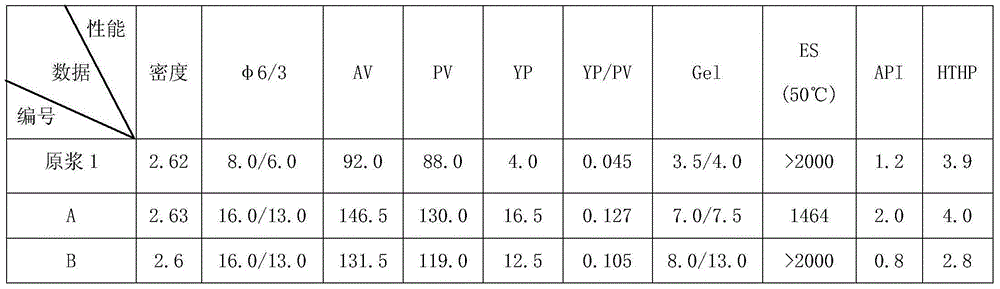

Embodiment 1

[0049] Example 1: A density of 2.80g / cm 3 , An ultra-high density oil-based drilling fluid with an oil-water ratio of 95:5. It is prepared from the following raw materials in weight percentage, base oil: 285.0ml; emulsifier: 6.0g; wetting agent: 4.8g; organic soil: 6.0g; fluid loss agent: 12.0g; cutting agent: 0.8g ; Alkalinity regulator: 6.0g; calcium chloride aqueous solution with a mass concentration of 20%: 15.0ml; weighting agent: 1382.0g.

[0050] The preparation method includes the following steps:

[0051] a. Add the base oil to the high mixing cup, then add the emulsifier and wetting agent, and stir at a high speed of 12000r / min for 10 minutes to make the system mix evenly;

[0052] b. Under the condition of maintaining stirring, add the alkalinity regulator and calcium chloride brine into the high stirring cup, and stir at 12000r / min for 10 minutes at a high speed to mix and stir the added components evenly;

[0053] c. Under the condition of maintaining stirring, add cutti...

Embodiment 2

[0057] Example 2: A density of 2.50g / cm 3 , An ultra-high density oil-based drilling fluid with an oil-water ratio of 9:1. It is prepared from the following raw materials in weight percentage, base oil: 270ml; emulsifier: 6.0g; wetting agent: 4.8g; organic soil: 7.2g; fluid loss agent: 12.0g; cutting agent: 0.5g; Alkalinity regulator: 6.0g; calcium chloride aqueous solution with a mass concentration of 20%: 30.0ml; weighting agent: 1125.0g.

[0058] The preparation method is the same as the preparation method described in Example 1.

Embodiment 3

[0059] Example 3: A density of 2.00g / cm 3 , An ultra-high density oil-based drilling fluid with an oil-water ratio of 9:1. It is prepared from the following raw materials in weight percentage, base oil: 270ml; emulsifier: 7.2g; wetting agent: 4.2g; organic clay: 5.1g; fluid loss agent: 12.0g; alkalinity regulator: 9.0g ; Calcium chloride aqueous solution with a mass concentration of 30%: 30.0ml; plugging agent: 6.0g; weighting agent: 600.0g.

[0060] The preparation method includes the following steps:

[0061] a. Add the base oil to the high mixing cup, then add the emulsifier and wetting agent, and stir at a high speed of 12000r / min for 10 minutes to make the system mix evenly;

[0062] b. While stirring at high speed, add the alkalinity regulator and calcium chloride brine into the high stirring cup, stir at 12000r / min for 10 minutes at a high speed to mix and stir the added components evenly;

[0063] c. Under high-speed stirring, add organic soil, fluid loss agent, and plugging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com