Culture method of dendritic cells and dendritic cells

A dendritic cell and culture method technology, applied in the field of dendritic cell and dendritic cell culture, can solve the problems of low induction maturation rate, low cell proliferation rate, poor antigen presentation performance, etc. rate and maturation rate, promoting improvement, and improving the effect of antigen presentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The culture method of dendritic cells provided by the invention comprises the following steps:

[0046] S1a, obtaining dendritic cell precursor mononuclear cells;

[0047] Draw 3-5ml of peripheral venous blood, dilute it with normal saline 1:1, then slowly add it to 3-5ml of Ficoll-Hypaque lymphocyte separation medium with a specific gravity of 1.077±0.001g / ml along the tube wall, and centrifuge at 1500r / min for 15 minutes , isolate and obtain peripheral blood mononuclear cells, and suspend the cells in RPMI1640 medium (purchased from Gibco) containing 10% fetal bovine serum, 100 U / mL penicillin, and 100 U / mL streptomycin at a concentration of 4×10 6 / ml, transferred to a six-well plate, 2ml / well, put the six-well plate at 37°C, 5% CO 2 Incubate in an incubator for 2 hours, remove the medium and suspended cells, put fresh RPMI1640 medium in each well, blow gently to blow up the cells on the wall, and collect the cell suspension, that is, a single dendritic cell precurs...

Embodiment 2

[0057] The difference from Example 1 is that the second inducer used in this example includes: 1000 U / ml rhTNF-α and 10 μg / ml tomato water-soluble extract.

[0058] Wherein, the preparation method of tomato water-soluble extract is:

[0059] Accurately weigh 0.5g of tomato powder in a 100mL polytetrafluoroethylene microwave extraction tube, add 25mL of ethanol extraction solution, fix the microwave extraction tube in the microwave extraction device, and connect it to a temperature sensor; set the heating program according to the experimental design, Heat to the predetermined extraction temperature of 55°C within 5 minutes. After the sample is extracted for 1 hour, it is cooled for 10 minutes, and then centrifuged at 4000 rpm for 5 minutes. Under the same conditions, the extraction residue was repeated twice, and the combined supernatant was passed through a 0.2 μm PTFE filter membrane for later use.

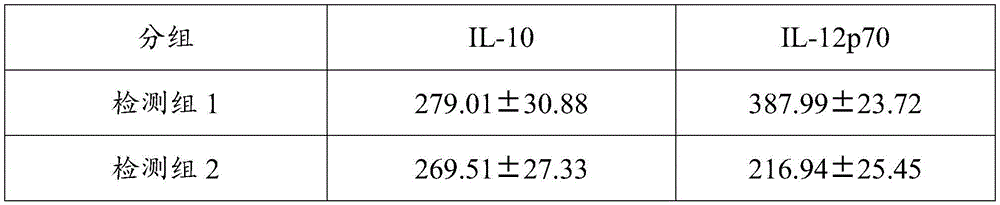

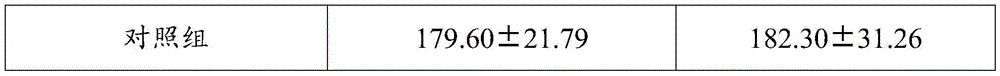

[0060] In order to further verify that the method for culturing dendritic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com