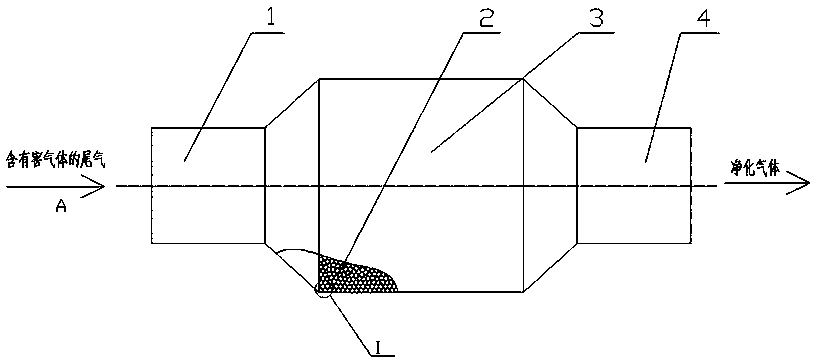

Catalyst for collecting particulate matter in diesel vehicle exhaust

A technology of exhaust particles and catalytic converters, which is applied in the field of diesel vehicle exhaust particulate matter capture catalytic converters, which can solve the problems of difficult device regeneration, large back pressure, and reduced specific surface area, and achieve strong adsorption effect, small ventilation resistance, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further illustrated below by specific examples.

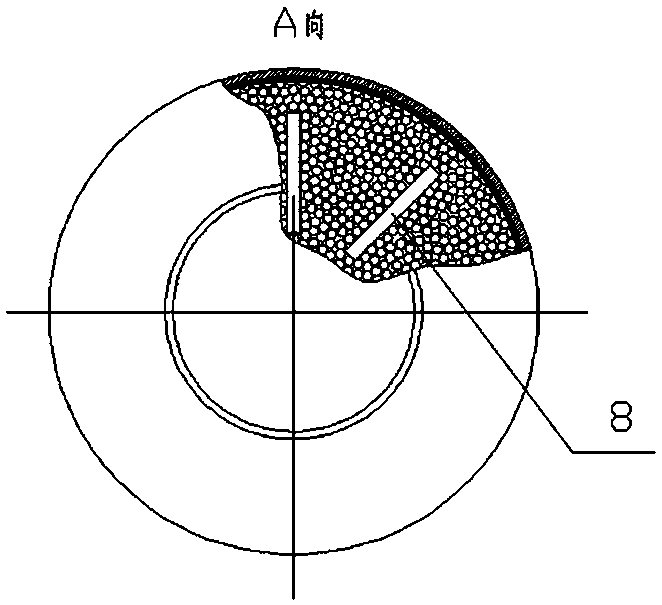

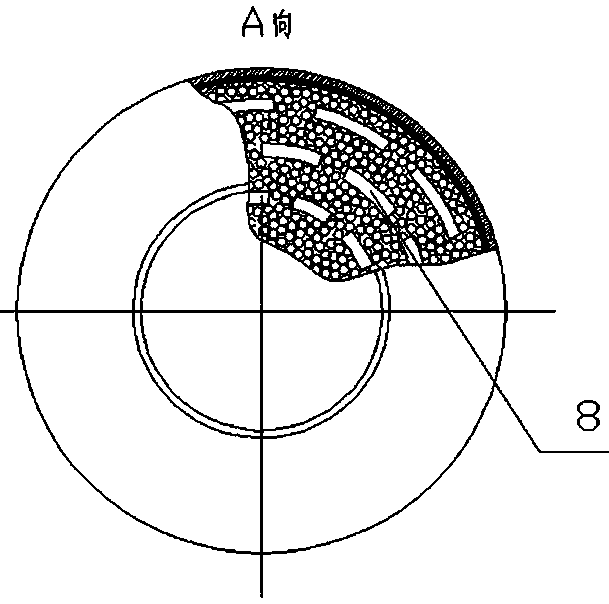

[0012] A kind of diesel vehicle exhaust particulate matter trapping catalytic converter according to the present invention, the main raw material used in a specific embodiment is inert alumina ceramic ball and bonding agent, inert alumina ceramic ball diameter 6mm, Al 2 o 3 Content 91%, corrosion resistance to acid, alkali and other organic solvents ≥ 95%. The adhesive composition and weight ratio are: titanium dioxide 53.7%, aluminum adhesive 23.33%, cerium zirconium oxide powder 11%, alumina powder 10.7%, sodium metavanadate 0.21%, monoethanolamine 0.15% %, 0.11% citric acid monohydrate, 0.8% palladium nitrate solution, the process of preparation is at first batching, mixing, then add appropriate amount of pure water to grind for 6 hours, and finally the concentration modulation, the weight ratio of pure water and other materials is 2.8: 1. The inner core of the collector in this embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com