Ultra-light low-frequency wire or cable for aerospace use

A wire and cable, ultra-light technology, used in insulated cables, cable/conductor manufacturing, conductor/cable insulation, etc. small diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

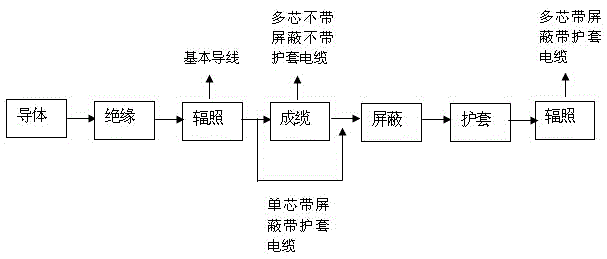

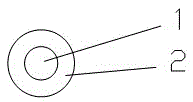

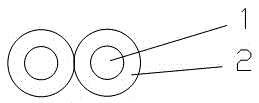

[0019] According to the accompanying drawings, the conductor is a compact stranded conductor, which is concentrically stranded on a wire and cable stranding machine with multiple strands of silver-plated copper monofilament or copper alloy monofilament, and is extruded through a mold after stranding;

[0020] The insulating layer is made of cross-linked-ethylene tetrafluoroethylene copolymer cross-linked material, and the ultra-thin cross-linked-ethylene tetrafluoroethylene copolymer cross-linked material is extruded on a high-temperature extruder by selecting a suitable extruded tube die, and is electronically Accelerator irradiation cross-linking;

[0021] The shielding layer is made of silver-plated copper wire, which is wound in one direction on a braiding machine or winding machine;

[0022] The sheath layer is made of cross-linked-ethylene tetrafluoroethylene copolymer cross-linked material, and the ultra-thin cross-linked-ethylene tetrafluoroethylene copolymer cross-lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com