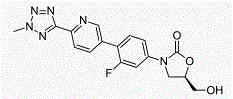

Stable tedizolid phosphate medicine composition

A technology of tedizolid and composition, applied in the field of tedizolid pharmaceutical composition and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

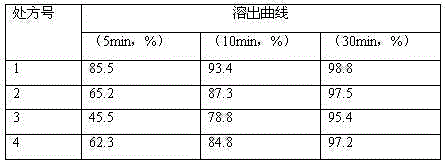

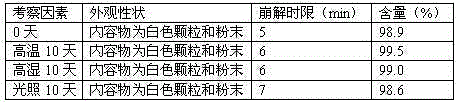

Examples

Embodiment 1

[0035] Tedizolid 200g

[0036] Croscarmellose Sodium 50g

[0037] Microcrystalline cellulose 70g

[0038] Micropowder silica gel 0.5g

[0039] Appropriate amount of 10% pregelatinized starch solution

[0040] Preparation

[0041] 1) Dry, pulverize and pass through a 100-mesh sieve to tedizolid, croscarmellose sodium and microcrystalline cellulose respectively to obtain tedizolid powder, croscarmellose sodium and microcrystalline cellulose respectively Cellulose powder;

[0042] 2) Take the prescribed amount of tedizolid, croscarmellose sodium and microcrystalline cellulose, mix well, then add 10% pregelatinized starch solution to make a soft material, pass through a 40-mesh sieve to granulate , to obtain tedizolid wet granules;

[0043] 3) Dry the above tedizolid wet granules at 60°C until the water content is less than 5%, to obtain tedizolid dry granules

[0044] 4) Pass the above-mentioned dry tedizolid granules through a 40-mesh sieve for granulation, then add a lub...

Embodiment 2

[0047] Tedizolid 400g

[0048] Croscarmellose Sodium 100g

[0049] Microcrystalline cellulose 140g

[0050] Micropowder silica gel 1g

[0051] Appropriate amount of 10% pregelatinized starch solution

[0052] Preparation

[0053] 1) Drying, pulverizing and passing tedizolid, croscarmellose sodium and microcrystalline cellulose respectively through a 100-mesh sieve to obtain tedizolid powder and microcrystalline cellulose powder respectively;

[0054] 2) Take the prescribed amount of tedizolid, croscarmellose sodium and microcrystalline cellulose, mix well, then add 10% pregelatinized starch solution to make a soft material, pass through a 40-mesh sieve to granulate , to obtain tedizolid wet granules;

[0055] 3) drying the above tedizolid wet granules at 60°C until the water content is less than 5%, to obtain tedizolid dry granules;

[0056] 4) Pass the above-mentioned dry tedizolid granules through a 40-mesh sieve for granulation, then add a lubricant, mix well, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com