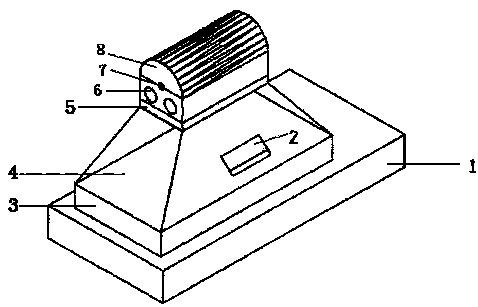

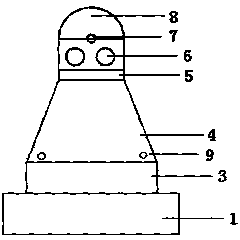

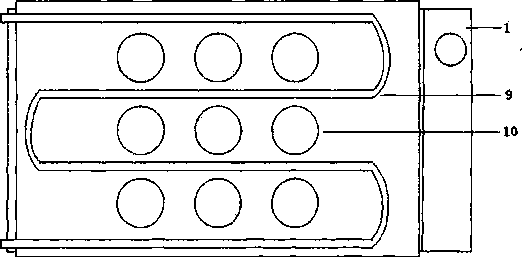

Water treatment photocatalytic reaction device

A photocatalytic reaction and water treatment technology, applied in the direction of light water/sewage treatment, etc., can solve the problems of difficult single batch experiment, low light energy utilization efficiency, in the initial stage, etc., to achieve temperature controllable, stable evaluation index, The effect of avoiding distractions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the experimental materials are a perfluorooctane sulfonate (PFOS) aqueous solution with an initial concentration of 100 μg / L and a homemade strontium-doped bismuth titanate visible light catalyst. Nine 100ml polypropylene plastic beakers were each loaded with 80ml of PFOS aqueous solution and 0.1g of strontium-doped bismuth titanate visible light catalyst, and magnetic stirring was used to uniformly mix the catalyst and the reaction solution, and the temperature of the reaction solution was kept at (20 ± 2 ) degrees, the xenon lamp intensity is 1000W. After 3 hours of reaction, the degradation rate of PFOS reached 70%, and the standard deviation of the degradation rate of pollutants in each beaker was 2.8%. This shows that the parallel sample analysis effect is ideal, and the device can provide good parallel sample analysis conditions.

Embodiment 2

[0031] The photocatalytic performance of different photocatalysts was evaluated by reliable parallel sample analysis results. Using PFOS aqueous solution with an initial concentration of 100 μg / L, 9 kinds (titanium, vanadium, manganese, iron, chromium, tungsten, nickel, antimony, strontium) doped bismuth titanate visible light catalysts were self-made. Nine 100ml polypropylene plastic beakers were each loaded with 80ml of PFOS aqueous solution and 0.1g of different kinds of doped bismuth titanate visible light catalysts, and magnetic stirring made the catalyst and the reaction solution evenly mixed, and the temperature of the reaction solution was maintained at (20 ± 2) degrees, the xenon lamp intensity is 1000W. After 3 hours of reaction, the degradation rates of PFOS were 0%, 80%, 0%, 5%, 0%, 5%, 10%, 5%, 65%. It can be seen that the multi-point photocatalytic reaction research device can evaluate the photocatalytic performance of various photocatalysts at a time, with high...

Embodiment 3

[0033] Use bismuth titanate visible light catalyst to degrade dye crystal violet and pentachlorophenol, respectively fill 80ml of 1mg / L dye crystal violet and pentachlorophenol solution in 2 100ml glass beakers, add 0.1g of each beaker Bismuth titanate visible light catalyst, magnetic stirring to uniformly mix the catalyst and the reaction solution, the temperature of the reaction solution is kept at (20±2)°C by a water bath, and the intensity of the xenon lamp is 1000W. After 3 hours of reaction, the degradation rates of the dye and pentachlorophenol reached 90% and 84% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com