Novel heat resistant coating and preparation method thereof

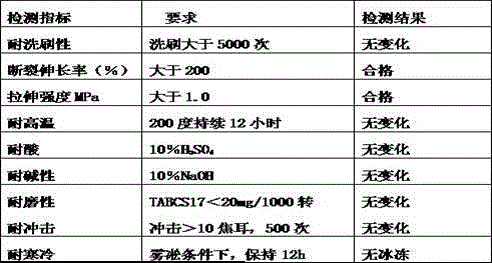

A heat-resistant paint, a new technology, applied in the field of paint, can solve the problems of incomplete compatibility of non-fluoride organic compositions, high manufacturing cost, application limitations, etc., and achieve improved heat resistance and water resistance, low cost, low cost. energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The present invention is a novel heat-resistant coating, which is made of the following raw materials in parts by weight: 3.5 parts of ultraviolet absorber, salicylate-based absorbent, 2 parts of diisooctylsuccinate sulfonate, 3 parts of - 4.3 parts of chloro-2-carboxypropyltrimethylammonium chloride, 4 parts of N-alkylacyl sarcosinate, 3.2 parts of sorbitan monooleate, 2.5 parts of bisoctyl zinc salt of thiophosphor , the emulsion is 8.5 parts of fluorocarbon emulsion, 0.1 part of anti-aging agent, and 0.15 part of sorbitol fatty acid ester.

[0020] The preparation method of above-mentioned novel heat-resistant paint, comprises the following steps:

[0021] 1) Weigh the UV absorber and diisooctyl succinate sulfonate according to the above formula, add 3-chloro-2-carboxypropyltrimethylammonium chloride and N-alkylacyl sarcosinate The last piece is placed in the reaction kettle, heated to 90°C, kept warm and cooled to room temperature after stirring for 4 hours;

[00...

Embodiment 2

[0027] The present invention is a novel heat-resistant coating, which is made of the following raw materials in parts by weight: 7.5 parts of ultraviolet absorber, i.e. copper benzyl series absorber, 5 parts of diisooctyl succinate sulfonate, 3 parts by weight - 5.6 parts of chloro-2-carboxypropyltrimethylammonium chloride, 6 parts of N-alkylacyl sarcosinate, 5.4 parts of sorbitan monooleate, 3.5 parts of phosphobisoctyl zinc salt , the emulsion is 10.8 parts of fluorocarbon emulsion, 0.2 part of anti-aging agent, and 0.32 part of sorbitol fatty acid ester.

[0028] The preparation method of above-mentioned novel heat-resistant paint, comprises the following steps:

[0029] 1) Weigh the UV absorber and diisooctyl succinate sulfonate according to the above formula, add 3-chloro-2-carboxypropyltrimethylammonium chloride and N-alkylacyl sarcosinate The last piece is placed in the reaction kettle, heated to 90°C, kept warm and cooled to room temperature after stirring for 5 hours...

Embodiment 3

[0035] The present invention is a novel heat-resistant coating, which is made of the following raw materials in parts by weight: 5.5 parts of ultraviolet absorber, i.e. copper benzyl series absorber, 3.4 parts of diisooctyl succinate sulfonate, 3 parts by weight - 4.8 parts of chloro-2-carboxypropyltrimethylammonium chloride, 5 parts of N-alkylacyl sarcosinate, 4.4 parts of sorbitan monooleate, 3.2 parts of bisoctyl zinc salt of thiophosphor , the emulsion is 9.2 parts of fluorocarbon emulsion, 0.15 part of anti-aging agent, and 0.22 part of sorbitol fatty acid ester.

[0036] The preparation method of above-mentioned novel heat-resistant paint, comprises the following steps:

[0037] 1) Weigh the UV absorber and diisooctyl succinate sulfonate according to the above formula, add 3-chloro-2-carboxypropyltrimethylammonium chloride and N-alkylacyl sarcosinate The last piece is placed in the reaction kettle, heated to 90°C, kept warm and cooled to room temperature after stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com